QUALITY PARTS

ON TIME AT

A FAIR PRICE

We provide a complete service

program for all your injection molding needs.

QUALITY PARTS

ON TIME AT

A FAIR PRICE

We provide a complete service

program for all your injection molding needs.

MOLD DESIGN

Utilizing full 3-D capabilities enables us to reduce costs and lead times while communicating detailed design intent with our customers.

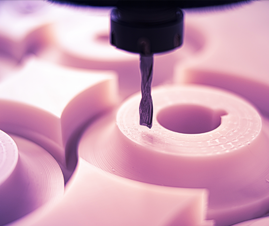

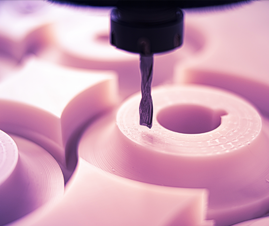

TOOLING SERVICES

No limit of classifications of mold, we are capable of simple pre-production to complex production molds

INJECTION MOLDING

No minimum order quantities. We have the ability to mold many types of inserts and match any color.

SECONDARY OPERATIONS

Our objective is to work with you and for you by also offering sonic welding, hot stamping, assembly, packaging & drop shipping per customer requirements.

MOLD DESIGN

Utilizing full 3-D capabilities enables us to reduce costs and lead times while communicating detailed design intent with our customers.

TOOLING SERVICES

No limit of classifications of mold, we are capable of simple pre-production to complex production molds

INJECTION MOLDING

No minimum order quantities. We have the ability to mold many types of inserts and match any color.

SECONDARY OPERATIONS

Our objective is to work with you and for you by also offering sonic welding, hot stamping, assembly, packaging & drop shipping per customer requirements.

Since 1971, LeVic Plastics has continually strived to offer the most precise, workable and economical prototype research and production facilities available.

Since 1971, LeVic Plastics has continually strived to offer the most precise, workable and economical prototype research and production facilities available.

ONE VENDOR ADVANTAGE

What is the “One Vendor Advantage?”

- It is when you vertically integrate your Custom Plastic Injection Mold from 3-5 stops to ONE smooth trackable process! Leveraging LeVic to manage your processes ensuring the best possible product every time.

NO MINIMUM ORDER QUANTITY

MAKING

“JUST IN TIME INVENTORY”

POSSIBLE

WE ARE YOUR ONE STOP SHOP

We Build the Mold

We Make the Part

We Paint the Part

We Assemble the Part

We Ship the Part

NO MINIMUM ORDER QUANTITY

MAKING

“JUST IN TIME INVENTORY”

POSSIBLE

WE ARE YOUR ONE STOP SHOP

We Build the Mold

We Make the Part

We Paint the Part

We Assemble the Part

We Ship the Part

WHY WE USE ALUMINUM MOLDS:

- The cost of machining is significantly less than with hardened steel molds.

- Modifications are easier, faster and less expensive.

- Delivery is typically at one-fourth to one-third the cost of a standard production mold.