In part one of our blog series, we covered a few different aspects of plastic mold manufacturing in Kansas City. We discussed a general overview of this method, some of the most common parts and products that are made using plastic mold manufacturing, and the four basic steps of the manufacturing process.

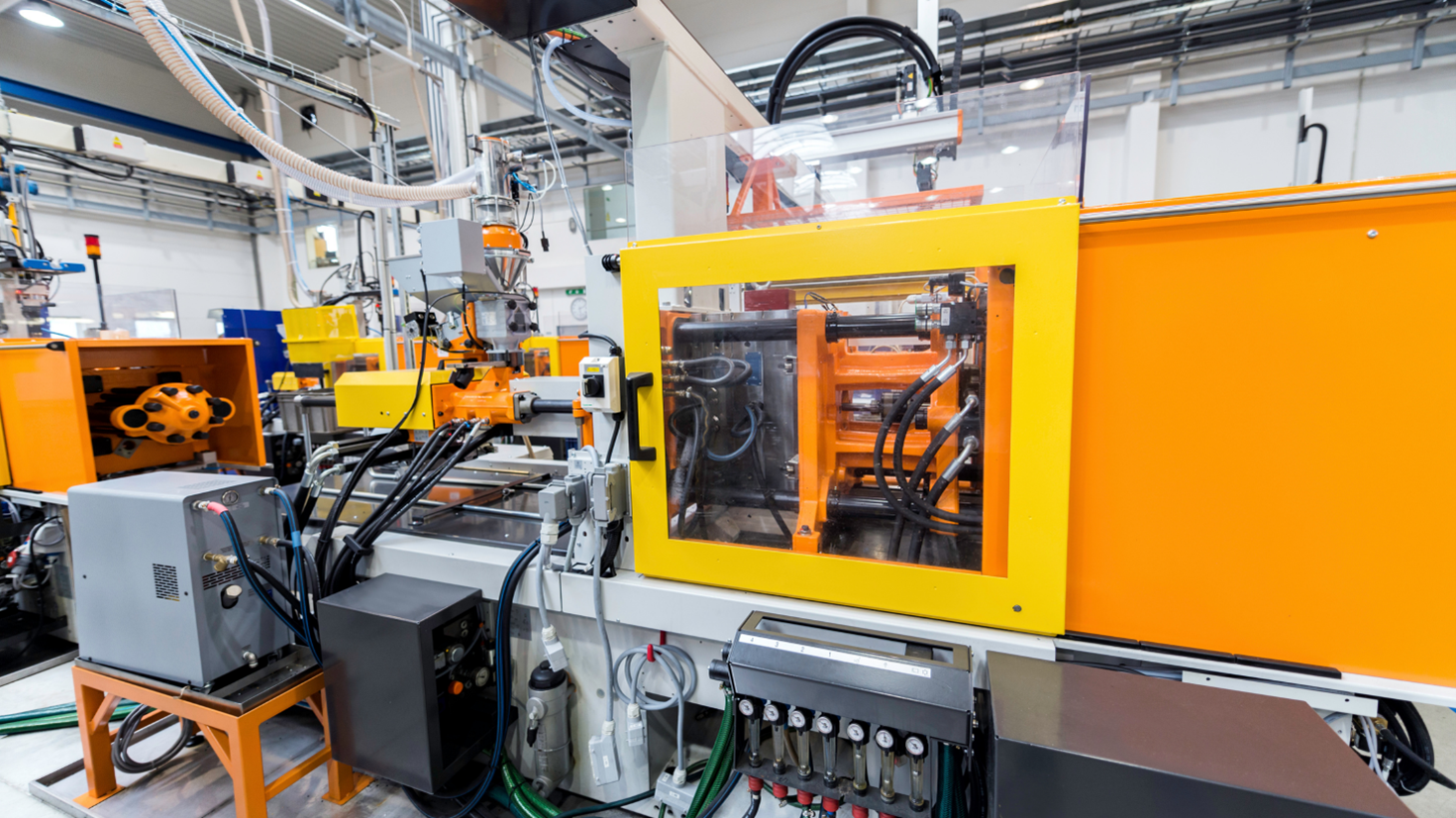

Today, we’ll wrap up this two-part series by describing some of the different plastics used during plastic mold manufacturing in Kansas City. We’ll also talk about some of the benefits that this production method offers and why it is considered one of the most reliable tooling services in Kansas City.

What are the Best Plastics for Plastic Mold Manufacturing in Kansas City?

Many plastic part manufacturers use thermoplastics for injection molding projects. A thermoplastic is a polymer that becomes a molten consistency once it is exposed to high temperatures. The molten then solidifies under cool temperatures. One reason why thermoplastics are popular amongst plastic mold manufacturers is that it can be heated and cooled multiple times before it eventually degrades. Most thermoset plastic materials will burn if reheated, making thermoplastics a better choice in most cases.

The Benefits of Plastic Mold Manufacturing in Kansas City

There are numerous reasons why plastic mold manufacturing is one of the most popular tooling services in Kansas City. The benefits are significant; including:

Less Waste – On average, there is around 20% waste when using plastic mold manufacturing compared to much higher waste rates when using other methods, such as CNC machining in Kansas City.

Make Complex Parts – Some parts and products require multiple pieces before they are complete. Plastic mold manufacturing can often be used to create very intricate shapes and designs using just one workpiece and eliminating the need for secondary operations.

Lower Costs – Since there is less waste and the materials are less expensive than other production methods, plastic mold manufacturing in Kansas City ends up being one of the most cost-effective production methods. Unused materials can also be recycled and used for future projects.

Consistent Quality – Plastic mold manufacturing is a very repeatable process. Manufacturers can create hundreds or thousands of parts in just a few hours. You can expect high-quality, consistent, and durable parts as long as the initial mold design is accurate.

That wraps up our two-part series on plastic mold manufacturing in Kansas City. We hope you found this information useful for your next production run.

Contact LeVic Plastics Today!

At LeVic Plastics, we have the staff, expertise, and equipment to assist with your next project. From large-scale orders to limited production runs in Kansas City, our LeVic team will complete your order with the utmost service, quality, and efficiency. We are located just outside the Kansas City area in Grandview, MO, and would love the opportunity to assist with your next project.

We specialize in numerous production methods, including injection molding, EDM machining in Kansas City, and CNC machining in Kansas City. We’ll work closely with you to find the best option for your next production run.

To get started, call (800) 231-1232 or click here to get a free quote. We look forward to hearing from you soon!