Types of Costs When Working With a Kansas City Plastic Injection Molding Company – Are you comparing the prices of different Kansas City plastic injection molding companies? If so, that’s probably a good idea. You should always check with other businesses to see how their rates compare with others in the injection molding industry.

When you’re comparing prices, is your Kansas City plastic injection molding company giving you a breakdown of where each dollar is going? After all, there’s the cost of materials, equipment costs, labor, and other factors. Here at LeVic Plastics, we have completed countless projects for our customers over the years. Whether it’s a massive order or limited production runs in Kansas City, we know that each project will have its own unique breakdown of expenses.

In this article, we’ll be discussing some of the different things you can expect to pay for to complete your next project with a Kansas City plastic injection molding company.

The Equipment Costs of a Kansas City Plastic Injection Molding Company

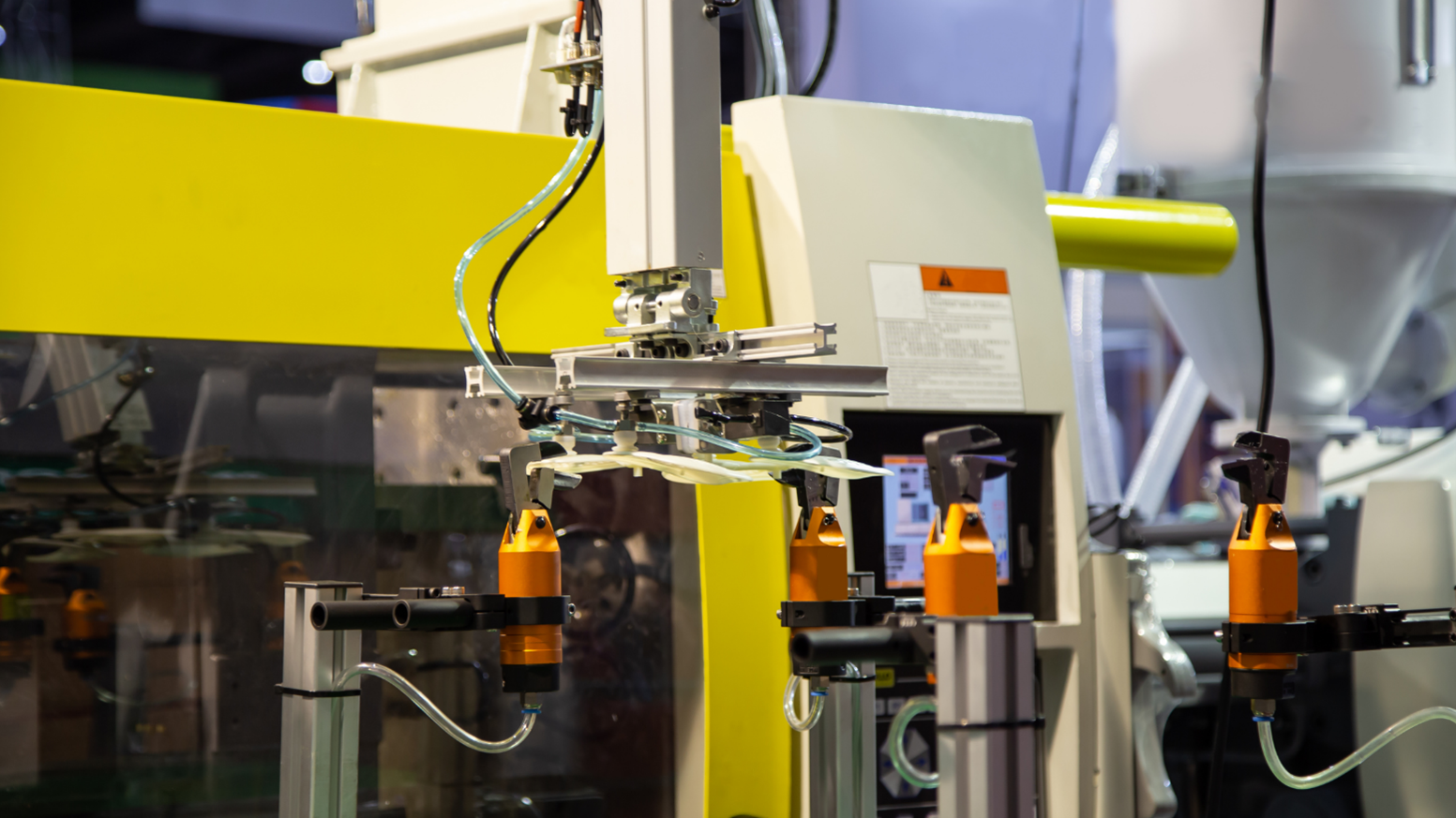

Different projects have their own unique equipment demands. Some projects can be completed with smaller desktop injection molding machines, while others require larger machines. No matter what size machine is used, there are costs to purchase, maintain, and use the machines.

If you are getting quotes from different Kansas City plastic injection molding companies for your project, you can expect to see a fee for equipment usage. These sometimes fall into the category of “service costs.”

Mold Costs

One of the largest expenses you’ll encounter during a plastic injection molding project is the cost of the mold. Molds can vary in overall price because they can be made using different methods, which directly impacts the pricing.

The mold can be made using 3D printing, EDM machining, or CNC machining in Kansas City. If your plastic injection molding company doesn’t offer one or more of these production methods, don’t stress. Many injection molding companies will outsource these projects to other facilities that have the necessary equipment already in place.

Labor Costs

Although a lot of the processes are automated at a typical Kansas City plastic injection molding company, there is still some manual labor to account for. There is the initial setup of the project, which means configuring the equipment to produce the desired mold. Next, there are repairs costs if the equipment were to malfunction during the project. Last, there are monitoring costs to account for. A professional needs to be on site during production to make sure the project runs seamlessly.

Injected Material Costs

There are various plastics that can be used to complete a production run. Some plastics cost more than others, which can affect the overall bottom line of your project. Also, the amount of material used will greatly determine the final price of the project. The final cost of the materials is usually defined by the model design, the material selected, and the size of the order.

Do You Need Help with Your Next Project?

Contact LeVic Plastics Today!

At LeVic Plastics, we have the staff, expertise, and equipment to assist with your next project. From large-scale orders to limited production runs in Kansas City Missouri, our LeVic team will complete your order with the utmost service, quality, and efficiency. We are located just outside the Kansas City area in Grandview, MO, and would love the opportunity to assist with your next project.

We specialize in numerous production methods, including injection molding, EDM machining in Kansas City, and CNC machining in Kansas City. We’ll work closely with you to find the best option for your next production run.

To get started, call (800) 231-1232 or click here to get a free quote. We look forward to hearing from you soon!