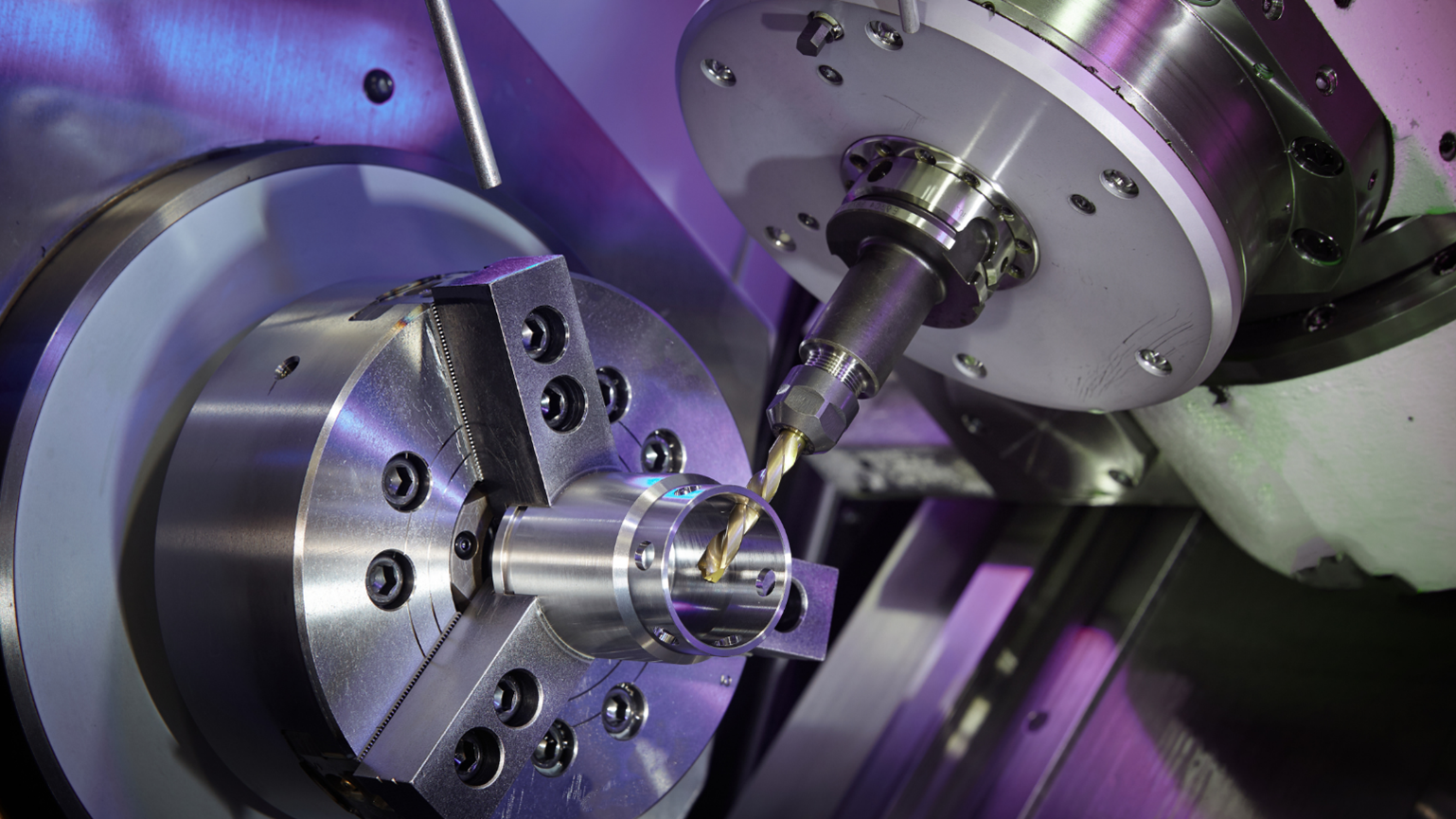

In order to be a highly respected company for CNC machining in Kansas City, the staff must take immense pride in their work. That’s precisely what we do at LeVic Plastics. We leave no stone unturned when it comes to creating high-quality parts and products using our advanced CNC machining methods.

Through our years of experience with CNC machining in Missouri, we have completed countless production runs using a wide range of materials. Our projects range from high-volume production runs to limited production runs in Kansas City. Each project requires the proper materials to ensure that all parts and products are made to the highest possible standards.

In this article, we’ll discuss four of the most commonly used materials for CNC machining in Kansas City. We hope you’ll find this information helpful and can use it to assist with your next project.

Materials for CNC Machining in Kansas City

Carbon Steel

For those who aren’t very familiar with carbon steel, it is a steel alloy that can contain up to 1% carbon and 1.6% manganese by weight. Many people who specialize in CNC machining in Missouri prefer carbon steel because of its affordability. You can find many cutting tools that are made with carbon steel at fair prices, and they offer high-quality machinability. Carbon steel tools are a great choice when working with magnesium, brass, and aluminum.

High-Speed Steel

When you hear the term “high-speed steel,” just know that it is just a slightly different form of carbon steel. High-speed steel is alloyed with extra materials like tungsten, chromium, vanadium, cobalt, and molybdenum. These elements give HSS its elevated temperature, durability, and abrasion resistance. All cutting tools made with high-speed steel will work well for constant high-speed cutting. Cutting tools with high-speed steel can be used to cut non-ferrous and ferrous metals.

Carbide

Carbide is a popular choice for CNC machining in Kansas City because of its durability. Cutting tools made with carbide tend to be very resistant to scratches, rusting, and heat. Many experts prefer carbide because it holds up better than steel when working in extreme conditions. Carbide is a combination of both carbon and tungsten.

Ceramic

Another durable choice for cutting tools is ceramic. All cutting tools made primarily with ceramic will boast superior heat and corrosion resistance. These cutting tools will also be chemically stable due to the fact that ceramic does not react with most metals that are used as workpieces. Ceramic tools are very productive, have a high cutting efficiency, and work well for high-speed finishing. Materials like hard steels, cast iron, and superalloys work best with ceramic tools.

Contact LeVic Plastics for All Your CNC Machining Needs

For over 50 years, LeVic Plastics has been a trusted source for a wide range of tooling services in Kansas City and throughout Missouri. We can assist with limited production runs in Kansas City or even the most massive production projects. We focus on creating high-quality parts and products to fit the needs of every client by using CNC machining, EDM machining, and plastic mold manufacturing in Kansas City.

Give us a call today at (800) 231-1232 or contact us online to find out more. We look forward to working with you soon!