Welcome to the fascinating world of EDM (Electrical Discharge Machining) right here in the heart of Kansas City! In this blog, our team at LeVic Plastics will take you on a journey through the basics of EDM machining in Kansas City. We’ll explore what it is, how it works, its applications, and why it’s a game-changer in the manufacturing industry. So, buckle up and get ready to dive into the electrifying world of EDM machining in Kansas City!

What is EDM Machining?

Let’s start with the basics. EDM machining in Kansas City is also known as:

- Spark Machining

- Spark Eroding

- Wire Burning

- Wire Erosion

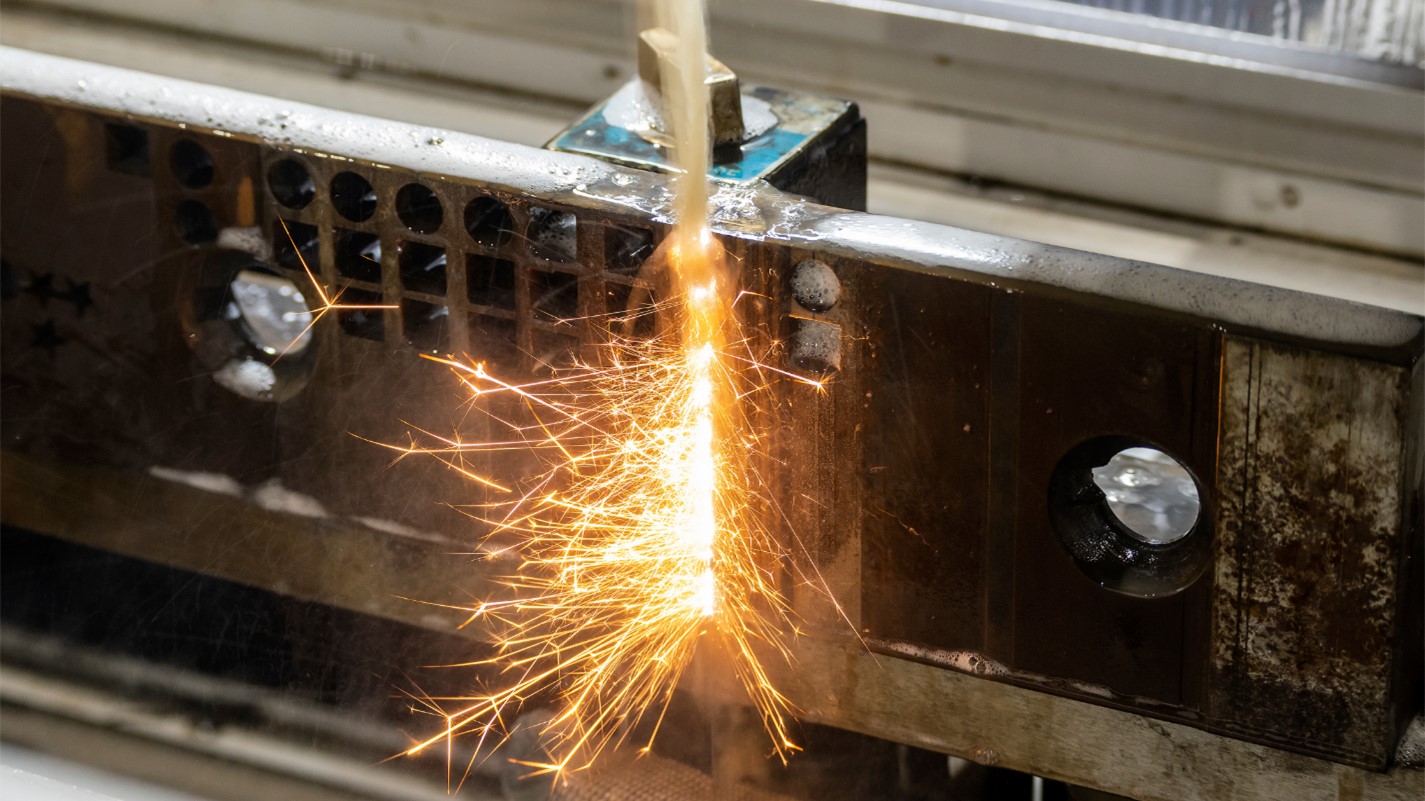

It is a non-traditional machining process used to shape hard materials, primarily metals, using electrical discharges. It’s like sculpting with lightning!

Unlike traditional machining methods that rely on physical contact between a cutting tool and the workpiece, Kansas City EDM machining uses electrical discharges to remove material from the workpiece. This makes it ideal for machining intricate shapes, tight tolerances, and hardened materials that are difficult to machine using conventional methods.

How Does EDM Machining Work?

Now, let’s get into the nitty-gritty of how EDM machining in Kansas City actually works. The process involves creating electrical discharges, or sparks, between an electrode (also known as a tool or a wire) and the workpiece. These electrical discharges generate intense heat, melting and vaporizing tiny particles of the workpiece material.

Here’s a simplified breakdown of the EDM machining process:

Tool and Workpiece Setup: The workpiece, typically made of a conductive material such as steel or titanium, is submerged in a dielectric fluid, such as oil or deionized water. The dielectric fluid acts as a medium for the electrical discharges and helps flush away debris from the machining area.

Electrode Selection: Depending on the desired shape and geometry of the final part, an electrode is selected. The electrode can be either a solid piece (for sinker EDM) or a thin wire (for wire EDM).

Electric Discharge: An electric potential difference is applied between the electrode and the workpiece, creating a series of high-frequency electrical discharges. These discharges generate intense heat, melting and vaporizing small portions of the workpiece material.

Material Removal: As the electrical discharges occur, material is removed from the workpiece in the form of tiny craters or craters. This process continues until the desired shape or feature is achieved.

Control and Precision: The entire process is carefully controlled by CNC (Computer Numerical Control) programming, which dictates the path and intensity of the electrical discharges. This allows for precise control over the machining process, ensuring that the final part meets the required specifications.

Types of EDM machining in Kansas City:

Here LeVic Plastics, we know that EDM machining can be categorized into two main types. There is sinker EDM (also known as conventional EDM) and wire EDM.

Sinker EDM: In sinker EDM, a solid electrode is used to create the desired shape or cavity in the workpiece. The electrode is lowered into the dielectric fluid, and electrical discharges occur between the electrode and the workpiece, eroding material from the workpiece.

Wire EDM: In wire EDM, a thin, electrically conductive wire is used as the electrode. The wire is fed through the workpiece, creating a precise cut or shape. Wire EDM is often used for cutting intricate shapes and profiles in hardened materials.

Applications of EDM machining in Kansas City:

Now that we understand how Kansas City EDM machining works, our team at LeVic Plastics will now explore some of its key applications across various industries:

Tool and Die Making: EDM machining is widely used in the production of molds, dies, and tooling for various manufacturing processes. Its ability to machine complex shapes and hardened materials makes it ideal for creating intricate molds and dies used in plastic injection molding, die casting, and stamping operations.

Aerospace and Defense: The aerospace and defense industries rely on EDM machining for manufacturing critical components with tight tolerances and complex geometries. EDM machining is used in the production of turbine blades, engine components, aerospace fasteners, and precision gears, among other applications.

Medical Devices: In the medical device industry, EDM machining is used to produce precision components for surgical instruments, implantable devices, and medical implants. Its ability to machine biocompatible materials such as titanium and stainless steel makes it well-suited for medical applications.

Electronics and Microfabrication: EDM machining is used in the production of electronic components, microelectronics, and microfabricated devices. Its ability to machine small features with high precision makes it ideal for producing micro-sized components used in electronic devices, sensors, and microfluidic devices.

Automotive Industry: The automotive industry utilizes EDM machining for producing precision components used in engines, transmissions, fuel systems, and vehicle chassis. EDM machining is particularly useful for machining hardened materials such as tool steels and carbide inserts used in automotive tooling and dies.

Why Choose EDM machining in Kansas City?

Now that we’ve explored the basics of EDM machining and its applications, our experts at LeVic Plastics will outline why it’s such a popular choice in the manufacturing industry:

Precision: EDM machining in Kansas City offers exceptional precision and accuracy, making it ideal for machining complex shapes, tight tolerances, and hardened materials.

Versatility: EDM machining can be used to machine a wide range of materials, including metals, alloys, and exotic materials such as titanium and inconel.

Surface Finish: EDM machining produces excellent surface finishes, with minimal burrs and no tool marks, eliminating the need for secondary finishing operations.

No Tool Wear: Since EDM machining does not rely on physical contact between the tool and the workpiece, there is no tool wear, allowing for consistent performance and dimensional accuracy over time.

Cost-Effective: While EDM machining in Kansas City may have higher upfront costs compared to conventional machining methods, it often proves to be cost-effective in the long run, especially for machining complex shapes and hardened materials.

EDM Machining in Kansas City and LeVic Plastics: Precision Redefined

At LeVic Plastics, we understand the importance of precision and reliability in manufacturing. That’s why we offer state-of-the-art Kansas City EDM machining services to meet the diverse needs of our clients across various industries.

Our Capabilities for EDM Machining in Kansas City:

Advanced EDM Machinery: We utilize the latest EDM machining technology, including sinker EDM and wire EDM machines, to produce precision components with tight tolerances.

Experienced Machinists: Our team of experienced machinists in Kansas City are well-versed in EDM machining techniques, ensuring optimal performance and quality for every project.

Quality Assurance: We adhere to strict quality control measures throughout the EDM machining process, ensuring that every component meets or exceeds industry standards.

Custom Solutions: Whether you need prototypes, small batches, or large-scale production runs, we offer custom EDM machining solutions in Kansas City that are tailored to your specific requirements.

Electrifying Innovation in Kansas City

In conclusion, EDM machining in Kansas City is a versatile, precise, and reliable machining process that has revolutionized the manufacturing industry. From aerospace components to medical devices and automotive parts, EDM machining plays a crucial role in producing precision-engineered components across various industries.

At LeVic Plastics, we’re proud to offer advanced Kansas City EDM machining services that deliver exceptional precision and quality for our clients in Kansas City and beyond. With state-of-the-art machinery, experienced machinists, and a commitment to excellence, we’re redefining precision machining one spark at a time.

So, whether you’re looking to prototype a new design, produce precision components, or streamline your manufacturing process, consider the electrifying innovation of EDM machining at LeVic Plastics. Let’s spark creativity and precision together!

Are you searching for top-notch injection molding services in Kansas City? Look no further than LeVic Plastics. Our team of injection molding professionals provide the best quality and fastest production run possible. We offer EDM machining in Kansas City, CNC machining, and other tooling services to ensure your project is completed properly and on time. At LeVic Plastics, we have the staff, expertise, and equipment to assist with your next project.

From large-scale orders to limited production runs in Kansas City, our LeVic team will complete your order with the utmost service, quality, and efficiency. We are located just outside the Kansas City area in Grandview, MO, and would love the opportunity to assist with your next project.

We specialize in numerous production methods, including injection molding, CNC machining in Kansas City, and other tooling services in Kansas City. We’ll work closely with you to find the best option for your next production run.

To get started, call (800) 231-1232 or click here to get a free quote.

We look forward to hearing from you soon!