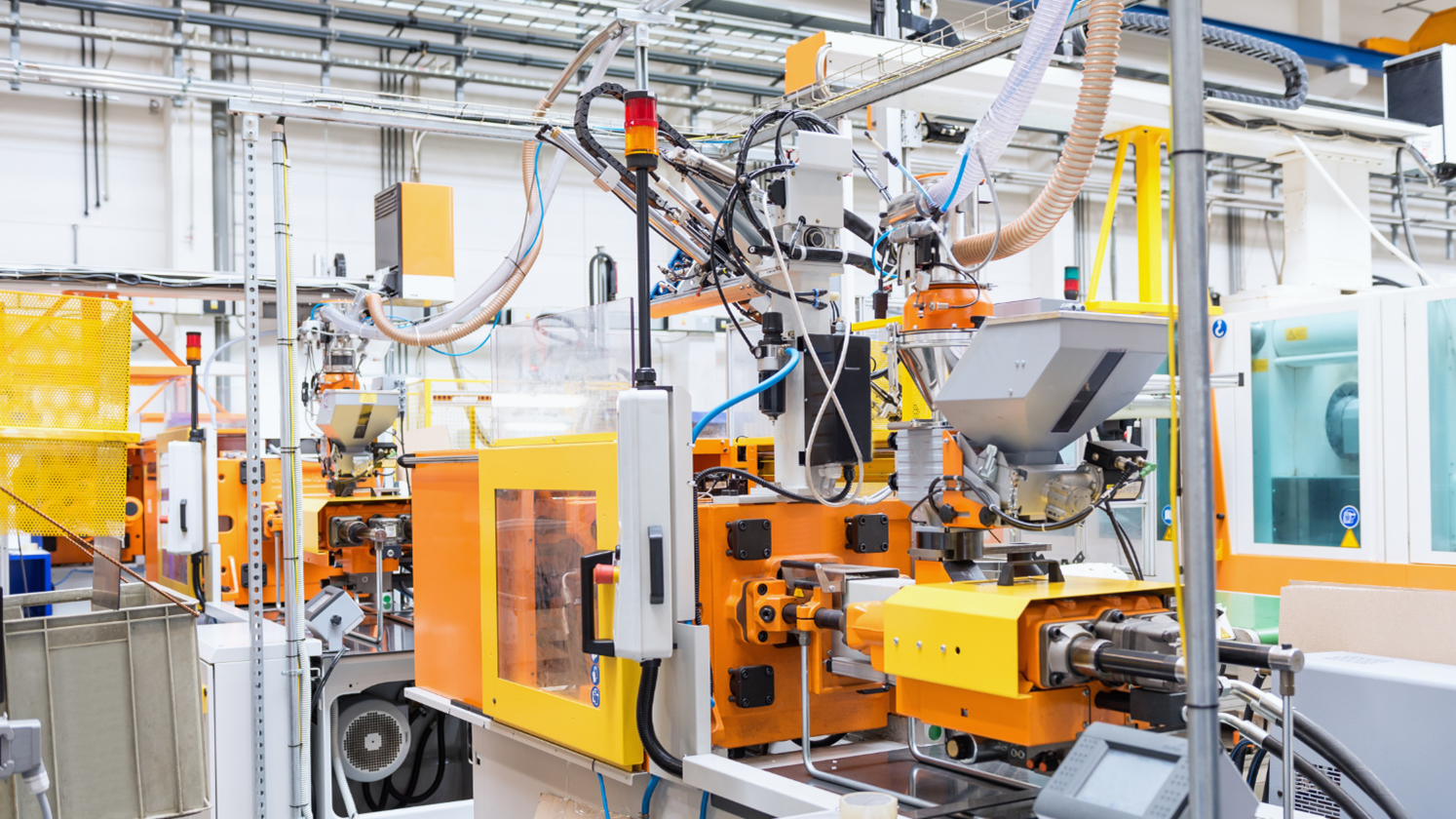

7 Similarities of Plastic Injection Molding and CNC Machining in Kansas — Although CNC machining in Kansas and plastic injection molding are two different processes, they share some similarities, especially in Kansas. Here are a few similarities between CNC machining and plastic injection molding in Kansas:

Use of Computer-Aided Design (CAD)

Both CNC machining in Kansas and plastic injection molding in Kansas use computer-aided design (CAD) software to create precise and complex designs. This allows for accuracy and consistency in the manufacturing process.

Material Selection for Injection Molding and CNC Machining in Kansas

Both CNC machining and plastic injection molding involve the selection of materials that meet specific requirements. For example, in CNC machining, the material may need to be strong, durable, and resistant to wear and tear. In plastic injection molding, the material must be able to withstand the molding process and produce a finished product that meets specific criteria.

Precision and Accuracy for CNC Machining and Plastic Injection Molding in Kansas

Both processes require precision and accuracy in the production of parts. CNC machines and plastic injection molding machines are capable of producing highly precise parts, with tolerances as small as thousandths of an inch. This level of accuracy is important in industries such as aerospace, medical device manufacturing, and automotive manufacturing, where even small deviations can have significant consequences.

Quality Control

Both processes require rigorous quality control measures to ensure that the finished product meets the required specifications. For CNC machining in Kansas, this may involve inspecting the parts with precision measuring equipment such as micrometers or calipers. For plastic injection molding, this may involve inspecting the parts for defects, such as flash or warping, before they are sent for further processing or assembly.

Skilled Workforce

Both CNC machining and plastic injection molding require a skilled workforce to operate the machines and carry out the necessary tasks. In Kansas, there are vocational training programs and apprenticeships available for both CNC machining and plastic injection molding, which help to develop the skills needed for these industries.

Versatility of Injection Molding and CNC Machining in Kansas

Both CNC machining and plastic injection molding offer versatility in terms of the types of parts that can be produced. CNC machines can be used to produce parts from a variety of materials, including metal, plastic, and wood. Plastic injection molding can produce parts in a range of sizes and shapes, from small intricate components to large parts such as automotive body panels.

Efficiency and Cost-Effectiveness

Both processes offer efficiency and cost-effectiveness benefits. CNC machining in Kansas can produce parts with high precision and accuracy in a shorter amount of time than traditional machining methods, leading to faster production times and reduced costs. Similarly, plastic injection molding in Kansas can produce large quantities of parts quickly and efficiently, reducing the overall cost of production.

Overall, CNC machining and plastic injection molding share similarities in terms of their reliance on CAD software, material selection, precision, accuracy, quality control, and the need for skilled workers. By understanding these similarities, individuals in these industries can leverage their knowledge and skills to improve their performance and contribute to the success of their organizations.

Are you searching for top-notch injection molding services in Kansas? Look no further than LeVic Plastics. Our team of injection molding professionals provide the best quality and fastest production run possible. We offer EDM machining in Kansas, CNC machining, and other tooling services to ensure your project is completed properly and on time. At LeVic Plastics, we have the staff, expertise, and equipment to assist with your next project.

From large-scale orders to limited production runs in Kansas, our LeVic team will complete your order with the utmost service, quality, and efficiency. We are located just outside the Kansas area in Grandview, MO, and would love the opportunity to assist with your next project.

We specialize in numerous production methods, including injection molding, CNC machining in Kansas, and other tooling services in Kansas. We’ll work closely with you to find the best option for your next production run.

To get started, call (800) 231-1232 or click here to get a free quote.

We look forward to hearing from you soon!