For any project that will be done using CNC machining in Missouri, the decision has to be made as to what to specific style of machining you will be using. There are several different options to choose from, but two of the most common methods are turning and milling.

Although both methods have proven to be very reliable and successful over the years, it may be hard to decide which of the two methods are best suited for a given project. As a leader in CNC machining in Kansas City, LeVic Plastics is here to help you determine which method is best for your production needs.

Defining Turning

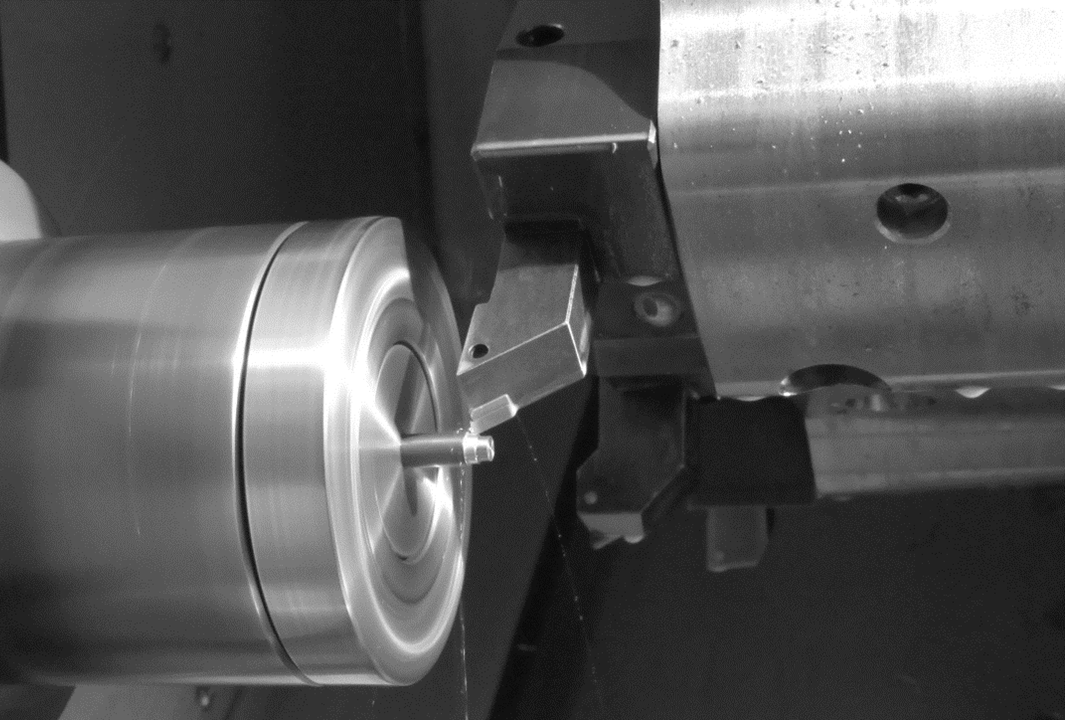

The simplest way to define turning when it comes to CNC machining in Missouri, it’s a process involving a CNC machine or lathe and a cutting tool to remove materials from a workpiece. During this procedure, the workpiece will move while the cutting tool remains locked in the same position.

The friction between the workpiece and the cutting tool will remove the outside edges of the workpiece while it continuously spins. Although turning is similar to other processes like “boring,” it differs because boring is used to extract materials on the inner areas of a workpiece, while turning removes the exterior layers.

Defining Milling

What makes milling different than turning is that the two most important parts of this process serve opposite roles. The workpiece remains stationary during milling while the cutting tool is the object that is constantly moving. Two of the main classifications for milling during CNC machining in Kansas City are face milling and peripherals milling.

Face milling involves cutting using the corners of the cutting tool, while peripherals milling does its cutting along the diameter of the cutting tool. Some common items made using milling include engine parts for cars and accessories that require lots of customizations.

Which Should I Pick: Turning? or Milling?

There is truly not a clear-cut answer on which of these CNC machining options is best. However, milling is typically used when working with flat, irregular surfaces. Turning is likely the best option for parts or products that will be round or cylindrical. Before beginning a large project, it is always best to speak to an expert when it comes to CNC machining in Missouri so that you can make an informed decision.

For over 40 years, LeVic Plastics has been making dependable products and parts for our valued customers, and we would love to assist you with your next big project. Give our team a call at (800) 231-1232, or contact us online to receive a free estimate. We look forward to working with you.