When it comes to manufacturing processes in Kansas City, there are a few key methods that stand out: CNC machining, EDM machining, and plastic injection molding. Each of these processes has its own set of pros & cons, and understanding them can help you make informed decisions about which process is right for your business needs.

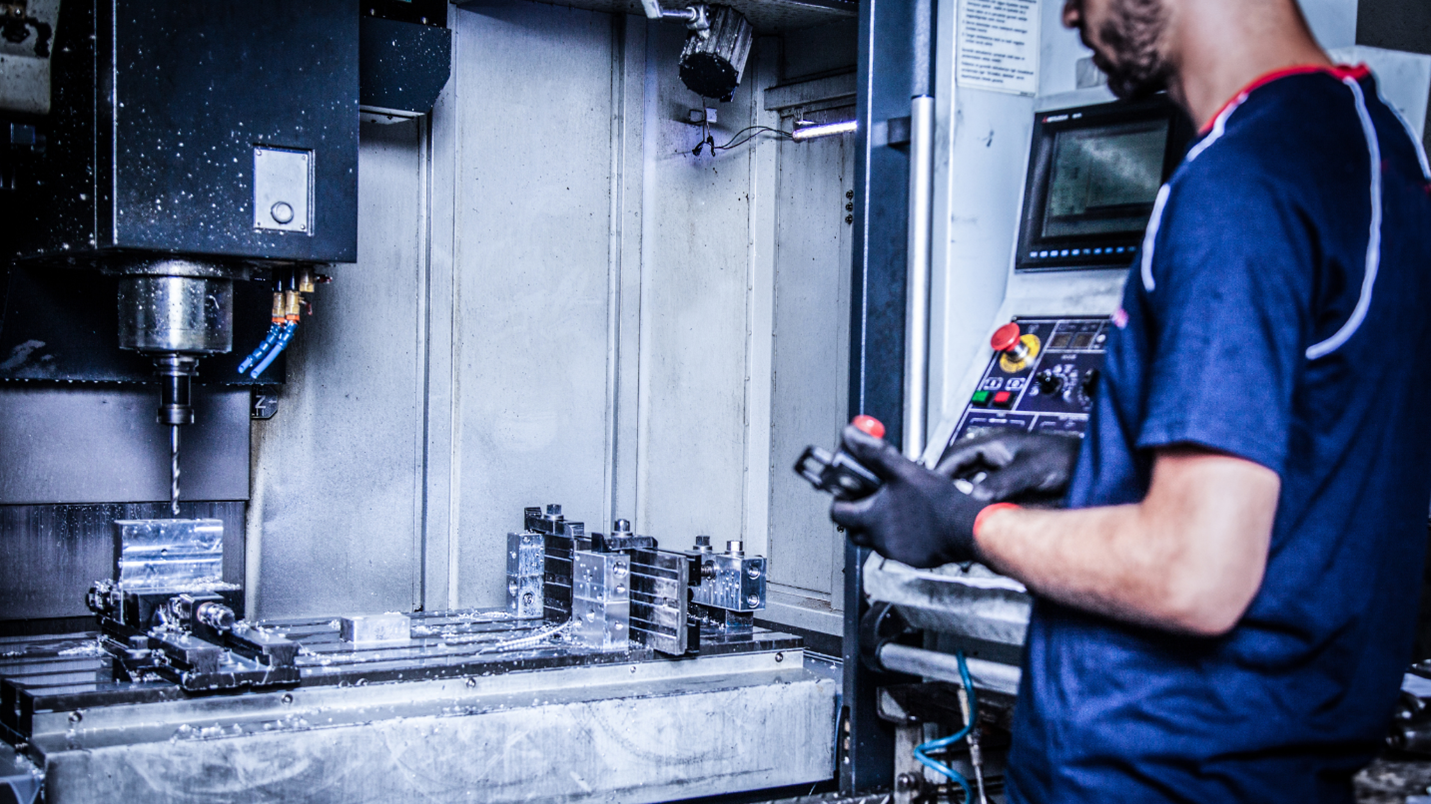

CNC Machining in Kansas City

CNC (Computer Numerical Control) machining is a versatile manufacturing process that uses automated tools to shape and cut metal and other materials. The process is precise, efficient, and customizable, making it ideal for a wide range of production needs.

Pros of CNC Machining in Kansas City:

- CNC machining is highly accurate, allowing for complex and precise shapes and cuts.

- The process is efficient and can be automated, reducing labor costs, and increasing production speed.

- CNC machines can be programmed to produce a wide range of products, making it a versatile production method.

- CNC machining can be used for a range of materials, including metal, plastic, and wood.

Cons of CNC Machining in Kansas City:

- CNC machines can be expensive to purchase and maintain.

- The setup time for CNC machines can be lengthy and costly.

- CNC machines require skilled operators, which can be difficult to find and retain.

- Production runs can be limited by the size of the CNC machine’s work area.

EDM Machining in Kansas City

EDM (Electrical Discharge Machining) is a manufacturing process that uses electrical sparks to shape metal and other materials. The process is very technical and can produce intricate shapes and cuts.

Pros of EDM Machining in Kansas City:

- EDM machining is highly precise, allowing for complex and intricate shapes and cuts.

- The process can be used for a range of materials, including metal, graphite, and ceramics.

- EDM machines can be used to produce small or large parts.

- The process can be used to make parts that are too difficult to produce with other manufacturing processes.

Cons of EDM Machining in Kansas City:

- EDM machines can be costly to purchase and maintain.

- The process can be slow, especially for larger parts.

- EDM machines require skilled operators, which can be difficult to find and retain.

- The process can produce small burrs and require additional finishing work.

Plastic Injection Molding in Kansas City

Plastic injection molding is a manufacturing process that uses a mold to shape plastic into a desired shape. This process is widely used in the production of consumer goods, medical devices, and other products.

Pros of Plastic Injection Molding in Kansas City:

- Plastic injection molding is a highly efficient process, allowing for fast and cost-effective production runs.

- The process can be used to produce high-quality and precise parts.

- Injection molding can be used for a range of plastic materials.

- The process can produce complex shapes and cuts.

Cons of Plastic Injection Molding in Kansas City:

- The setup time for injection molding can be lengthy and costly.

- Tooling costs for injection molding can be expensive.

- The process generates waste material, which can be costly to dispose of.

- Injection molding is limited to producing parts that can fit within the mold’s size and shape limitations.

All three of these manufacturing processes – CNC machining, EDM machining, and plastic injection molding – offer unique benefits and challenges. Depending on the specific needs of your business, one of these processes may be a better fit than the others. Understanding the pros and cons of each process can help you make informed decisions about which method to use for your next production run.

When deciding between CNC machining, EDM machining, and plastic injection molding, it’s important to consider not only the advantages and disadvantages of each process but also the specific needs of your business. Factors such as production volume, material type, and part complexity can all play a role in determining which process is right for your needs.

For businesses that require a high degree of precision and complex shapes and cuts, CNC machining may be the best option. The process is highly customizable and accurate, making it ideal for industries such as aerospace or medical devices. However, due to the cost of CNC machines and the specialized skill set required to operate them, it may not be the most cost-effective option for smaller businesses or low-volume production runs.

EDM machining, on the other hand, is an excellent choice for industries that require intricate shapes and cuts that cannot be achieved through traditional cutting or machining methods. While it is a slower process than CNC machining, the high level of precision and capability to work with materials such as graphite or ceramics make it an asset for advanced production needs.

Plastic injection molding, on the other hand, is best suited for high-volume production runs of parts with a consistent shape and size. The process is highly efficient and cost-effective for producing large quantities of parts, making it ideal for industries such as automotive or consumer goods. However, the tooling costs associated with injection molding can be significant, making it less practical for small-scale production runs.

Overall, each of these manufacturing processes has its own strengths and weaknesses. Understanding the specific needs of your business and production needs can help guide your decision-making process and ensure that you are making the most informed choices for your production needs.

Are you searching for top-notch injection molding services in Kansas City? Look no further than LeVic Plastics. Our team of injection molding professionals provide the best quality and fastest production run possible. We offer EDM machining in Kansas City, CNC machining, and other tooling services to ensure your project is completed properly and on time. At LeVic Plastics, we have the staff, expertise, and equipment to assist with your next project.

From large-scale orders to limited production runs in Kansas City, our LeVic team will complete your order with the utmost service, quality, and efficiency. We are located just outside the Kansas City area in Grandview, MO, and would love the opportunity to assist with your next project.

We specialize in numerous production methods, including injection molding, CNC machining in Kansas City, and other tooling services in Kansas City. We’ll work closely with you to find the best option for your next production run.

To get started, call (800) 231-1232 or click here to get a free quote.

We look forward to hearing from you soon!