One of the most proven manufacturing methods is using custom plastic injection molds in Missouri. Plastics are a significant component for countless products that we use today, and one of the most efficient ways to construct these products is by using plastic injection molding services in Missouri.

Although the manufacturing process for any product is very detail-oriented, this article will help provide the basic steps of custom plastic injection molding in Missouri. The process can be broken down into three different steps, which are:

- Designing the Product

- Designing the Mold

- Manufacturing the Product

Designing the Product

All three parts of injection molding are important to making a quality product, but the design process is a critical step when it comes to saving time, effort, and money. When designing the product, the designer should focus heavily on:

- Manufacturability

- Aesthetics

- Function

- Assembly

Using computer–aided design software is the most common way to work on the specifications of the product. Many companies specializing in custom injection molding in Missouri will use a team of design engineers to work together to improve a specific project’s complexities. Having multiple people reviewing the design will help find more improvements for potential manufacturing flaws in the future.

Designing the Mold

Once the product design phase is complete, a mold will be designed and manufactured so that the product can be produced. Custom plastic injection molds in Missouri are typically comprised of one of the following materials:

- Hardened Steel – Most expensive but most durable mold option, smart choice for large orders

- Pre-Hardened Steel – Not quite as durable as hardened steel, but less expensive

- Aluminum – Typically used for smaller order quantities, less expensive than steel options

During the mold design process, it is another opportunity for engineers to fix any defects before the molds are manufactured. Those involved with the design process will consider many factors, including order size and complexity of the product design.

Manufacturing the Product

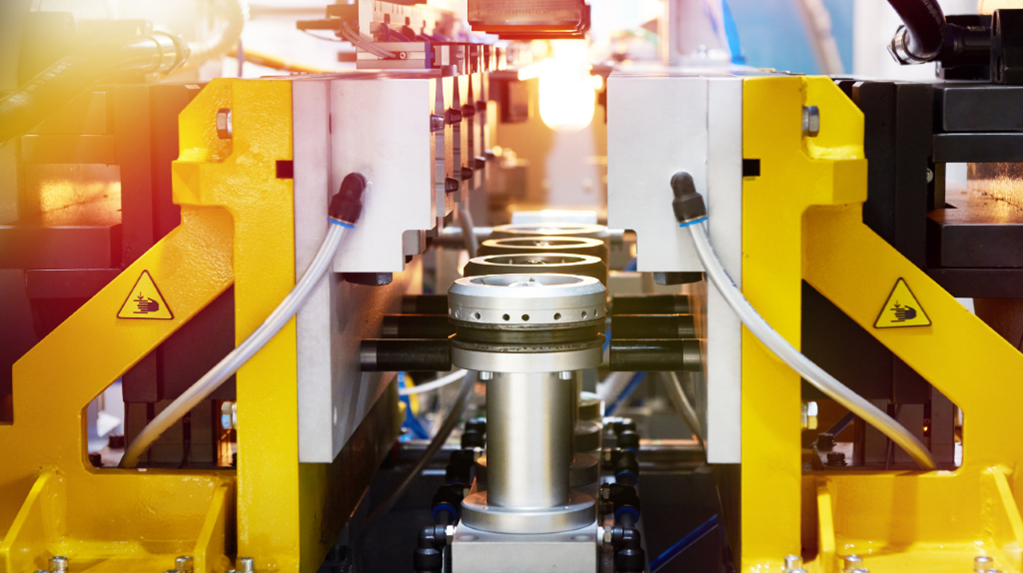

Once the product and mold designs are completed and approved, then production can begin. Plastic is heated to the desired temperature and then fed through a gate and on to the mold. Once the mold is filled with plastic, a machine places pressure on the plastic and mold for the required time to shape the product and then let it cool.

This process is repeated numerous times until the entire project is complete. In a nutshell, that’s how custom injection molding in Missouri works!

If you need parts or a product manufactured and are interested in plastic injection molding services in Missouri, give LeVic Plastics a call at (816) 761-8484 or contact us online. Since 1971, LeVic Plastics has specialized in providing customers with complete service programs for all their injection molding needs.

We look forward to working with you!