Missouri is a state known for its rich manufacturing history. The “Show Me State” hosts a diverse array of companies that contribute significantly to various industries. Among the many manufacturing processes available, insert molding has gained particular prominence in Missouri.

But what exactly do Missouri insert molding companies do? Why is insert molding an essential process for so many businesses? In this blog, we’ll delve into the fascinating world of insert molding, exploring its applications, advantages, and the role it plays in Missouri’s manufacturing landscape.

Understanding What Missouri Insert Molding Companies Do

Insert molding is a specialized injection molding process that combines plastic and metal or other materials into a single, integrated product. This method is commonly used to create complex, multi-material components that feature metal inserts or other substrates. By melting the plastic around an insert, insert molding forms a strong, durable bond, resulting in a seamless, one-piece assembly.

The versatility of insert molding is one of its most appealing aspects. It can be used with a wide range of insert materials, such as metal, plastic, ceramics, or even electronics, allowing manufacturers to produce parts with enhanced functionalities and characteristics. To fully grasp the significance of Missouri insert molding services, let’s explore some of the key applications and benefits of this process.

Key Applications for Missouri Insert Molding Companies

Insert molding serves a multitude of applications across various industries. The following are just a few areas where insert molding has proven indispensable:

- Automotive Industry

Missouri insert molding companies play a crucial role in the automotive sector. It’s used to manufacture a wide range of components, including electrical connectors, sensor housings, and interior parts like dashboard switches. These parts require a combination of metal and plastic elements, which insert molding efficiently delivers.

- Medical Devices

The medical industry relies heavily on insert molding to create complex devices with precision and consistency. Components like syringe plungers, catheters, and surgical instruments often incorporate metal or ceramic inserts within plastic housings to ensure safety, reliability, and functionality.

- Electronics

In the world of electronics, compactness and precision are paramount. Missouri insert molding companies are used to encapsulate delicate electronic components within plastic housings, providing protection against environmental factors and physical damage. This is particularly important in applications like connectors, relays, and sensor enclosures.

- Consumer Goods

Many everyday products benefit from the capabilities of insert molding. These range from kitchen appliances and power tools to toys and sporting equipment. Insert molding allows manufacturers to create user-friendly, durable, and aesthetically pleasing products by combining various materials effectively.

- Aerospace and Defense

The aerospace and defense sectors rely on Missouri insert molding services to produce components that meet stringent standards. Items such as avionics housings, drone parts, and defense system components often utilize this process to maintain durability and precision under demanding conditions.

Advantages of Using Missouri Insert Molding Companies

Insert molding offers several advantages for many Missouri manufacturers. Here are some of the key benefits associated with insert molding in Missouri:

- Enhanced Component Strength

The combination of plastic and metal, or other materials, results in components that are stronger and more resilient. This is particularly advantageous in applications where mechanical stress, temperature variations, or exposure to harsh environments are concerns.

- Improved Design Flexibility

Missouri insert molding companies allow for intricate and innovative product designs. By integrating diverse materials, manufacturers can create components with varying textures, colors, and properties. This flexibility can enhance the aesthetics and functionality of the final product.

- Cost-Efficiency

The initial tooling costs for Missouri insert molding services may be higher than traditional methods. However, the overall cost-effectiveness becomes evident in the long run. The ability to combine multiple components into a single part can reduce:

- Assembly Costs

- Labor Costs

- Material Costs

- Streamlined Production

The integration of multiple processes into a single step simplifies production and reduces lead times. Missouri insert molding services can produce complex components efficiently, ensuring a quicker time-to-market for their products.

- Enhanced Precision

Insert molding delivers precise and consistent results, making it ideal for applications where tight tolerances and accuracy are crucial. This is particularly valuable in industries like healthcare and aerospace.

The Role of Missouri Insert Molding Companies

Missouri, with its strong manufacturing history and a skilled workforce, has become a hub for insert molding companies. These companies play a pivotal role in supporting various industries. At LeVic Plastics, we offer solutions that meet the unique demands of our clients. So, what exactly do insert molding companies do? And why is their presence in Missouri significant?

- Customized Solutions

Insert molding companies in Missouri specialize in providing customized solutions to businesses of all sizes. They can tailor their services to meet your specific requirements. It doesn’t matter whether you’re a small startup business in Missouri or a massive multinational corporation. Their ability to create intricate, multi-material components allows them to cater to a wide range of industries. Offering custom solutions makes them indispensable for businesses seeking unique solutions.

- Material Expertise

Missouri insert molding companies have a deep understanding of materials and their behavior during the molding process. They can advise clients on the best combination of materials to use. Insert molding companies in Missouri can help you achieve the desired properties for a given application. This expertise is particularly valuable in numerous industries. The automotive industry is where performance and durability are crucial.

- Quality Assurance

Quality is a top priority for Missouri insert molding companies. They implement rigorous quality control processes. These are in place to ensure that each component meets or exceeds industry standards. This commitment to quality is essential in industries like aerospace and medical. Product reliability can truly have life-or-death implications.

- Collaboration and Innovation

Insert molding companies in Missouri often collaborate with clients to drive innovation. They work closely with businesses to develop new designs. Insert molding companies also optimize existing designs while finding cost-effective solutions. This spirit of collaboration and innovation is invaluable. This is especially true for companies looking to stay ahead in competitive markets.

- Local Support and Quick Turnaround

Missouri insert molding companies provide businesses with local support and quick turnaround times. This proximity can be advantageous, allowing for close communication, rapid prototyping, and shorter lead times, all of which contribute to efficient project management.

- A Skilled Workforce

Missouri has a rich history of manufacturing. The Missouri workforce is known for being well-trained and experienced. This hold true for the machinists, engineers, and technicians working in insert molding companies. These valuable workers are skilled in operating machinery and managing the production process.

The Sustainability Aspect of Missouri Insert Molding Services

In recent years, sustainability has gained significant importance in manufacturing. Many Missouri insert molding companies are adopting environmentally friendly practices, such as recycling and reducing material waste. By optimizing production processes and using eco-friendly materials, they are contributing to a greener and more sustainable future.

Missouri insert molding companies are integral to the state’s thriving manufacturing landscape. They offer innovative, customized solutions for a wide range of businesses. Their expertise in creating components that seamlessly combine different materials is invaluable. These companies are responsible for ensuring product strength, precision, and durability.

As Missouri continues to be a hub for manufacturing, insert molding companies will play a vital role. These companies help to drive innovation, improve product design, and contribute to the growth of local industries. Their commitment to quality, sustainability, and collaboration makes them an essential part of the state’s economic development. Whether you’re in the automotive, medical, electronics, or aerospace sector, insert molding companies in Missouri are ready to meet your demands, providing you with efficient and cost-effective solutions.

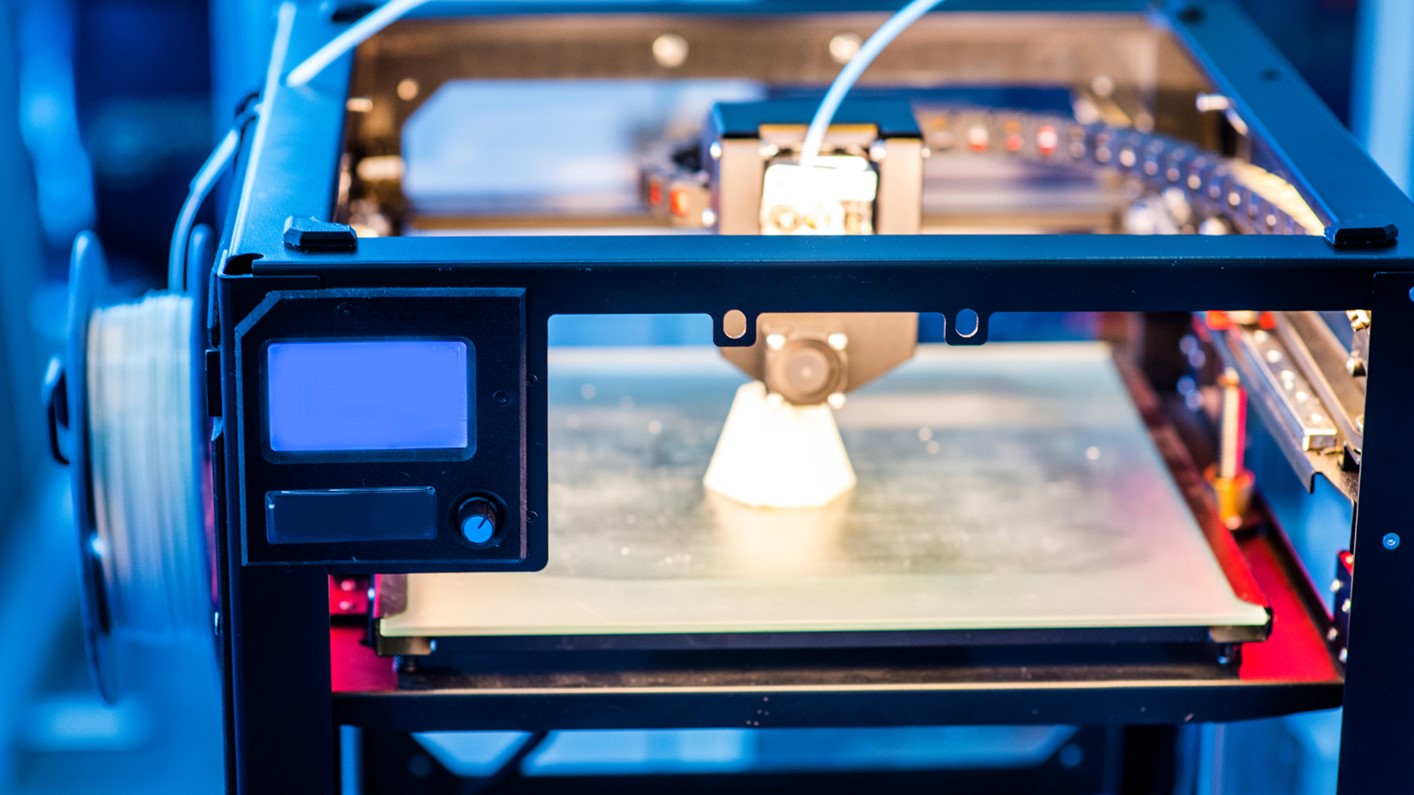

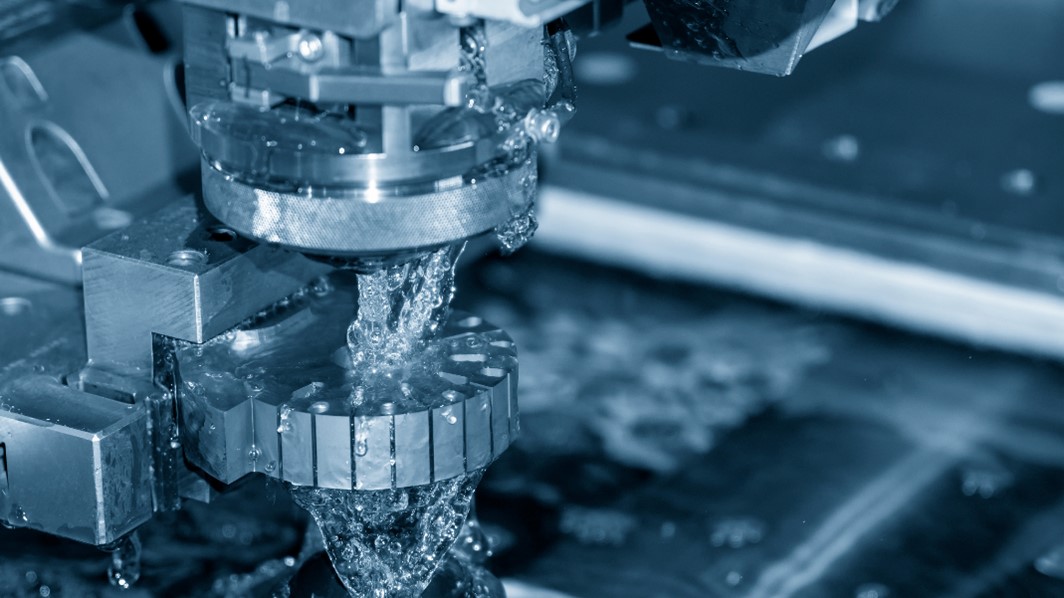

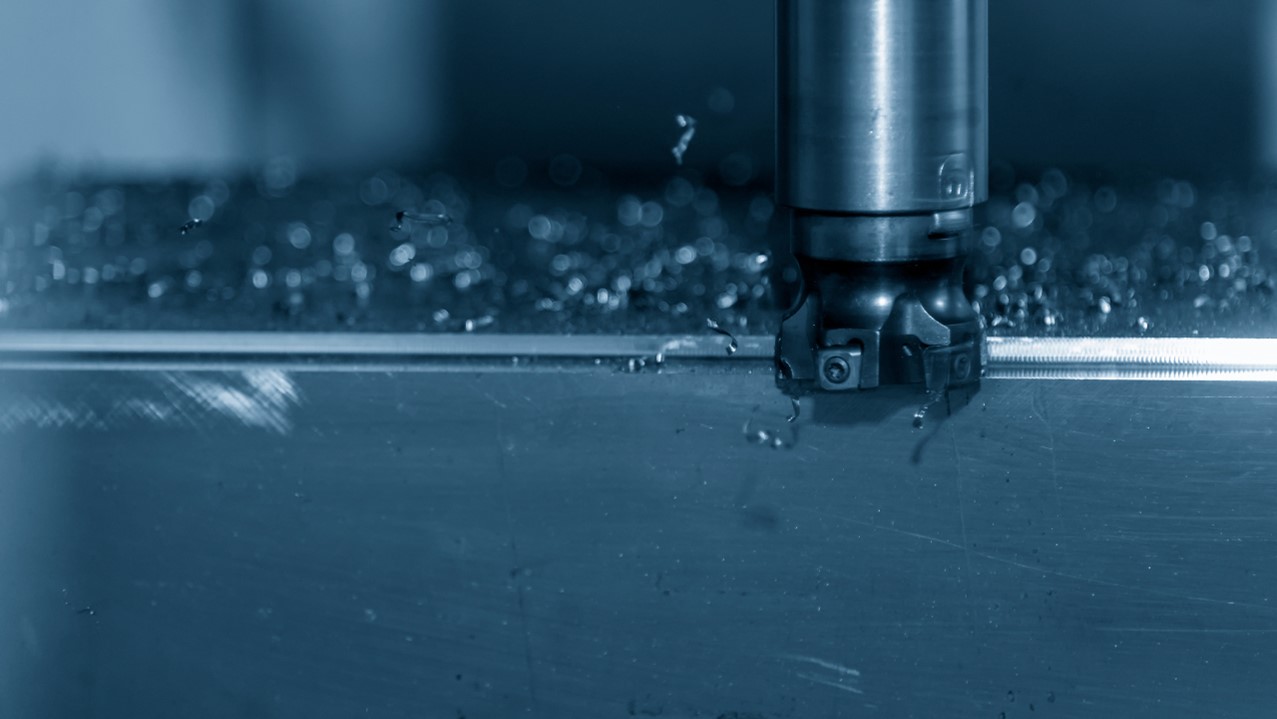

Are you searching for top-notch injection molding services in Kansas City? Look no further than LeVic Plastics. Our team of injection molding professionals provide the best quality and fastest production run possible. We offer EDM machining in Missouri, CNC machining, and other tooling services to ensure your project is completed properly and on time. At LeVic Plastics, we have the staff, expertise, and equipment to assist with your next project.

From large-scale orders to limited production runs in Missouri, our LeVic team will complete your order with the utmost service, quality, and efficiency. We are located just outside the Kansas City area in Grandview, MO, and would love the opportunity to assist with your next project.

We specialize in numerous production methods, including injection molding, CNC machining in Missouri, and other tooling services in Missouri. We’ll work closely with you to find the best option for your next production run.

To get started, call (800) 231-1232 or click here to get a free quote.

We look forward to hearing from you soon!