The 7 Short Chapters of Plastic Injection Molding Services in Kansas — In a world where plastics reign supreme, plastic injection molding is the unsung hero of manufacturing. It’s the process behind the countless plastic products that surround us. At LeVic Plastics, we know that everyday items are crafted using plastic injection molding services in Kansas. Thes include everything from toothbrushes and bottle caps to complex components in automotive and medical devices.

Today, we’re going to embark on a journey to unravel the secrets of plastic injection molding, with LeVic Plastics – one of the top plastic injection molding services in Kansas – as our guide.

Chapter 1: The Prelude – What are Plastic Injection Molding Services in Kansas?

Let’s keep things simple – so we’ll begin with the basics. Plastic injection molding in Kansas is a manufacturing process that involves injecting molten plastic material into a mold cavity. This cavity is the inverse of the desired part. So, that means when the plastic cools and solidifies, it takes on the shape of the mold. Sounds simple, right? Well, there’s more to it than meets the eye.

Chapter 2: The Cast of Characters – Essential Components for Plastic Injection Molding Services in Kansas

Before we dive into the nitty-gritty, let’s meet the key players in this production:

The Injection Molding Machine: This is the star of the show, responsible for melting and injecting plastic material into the mold.

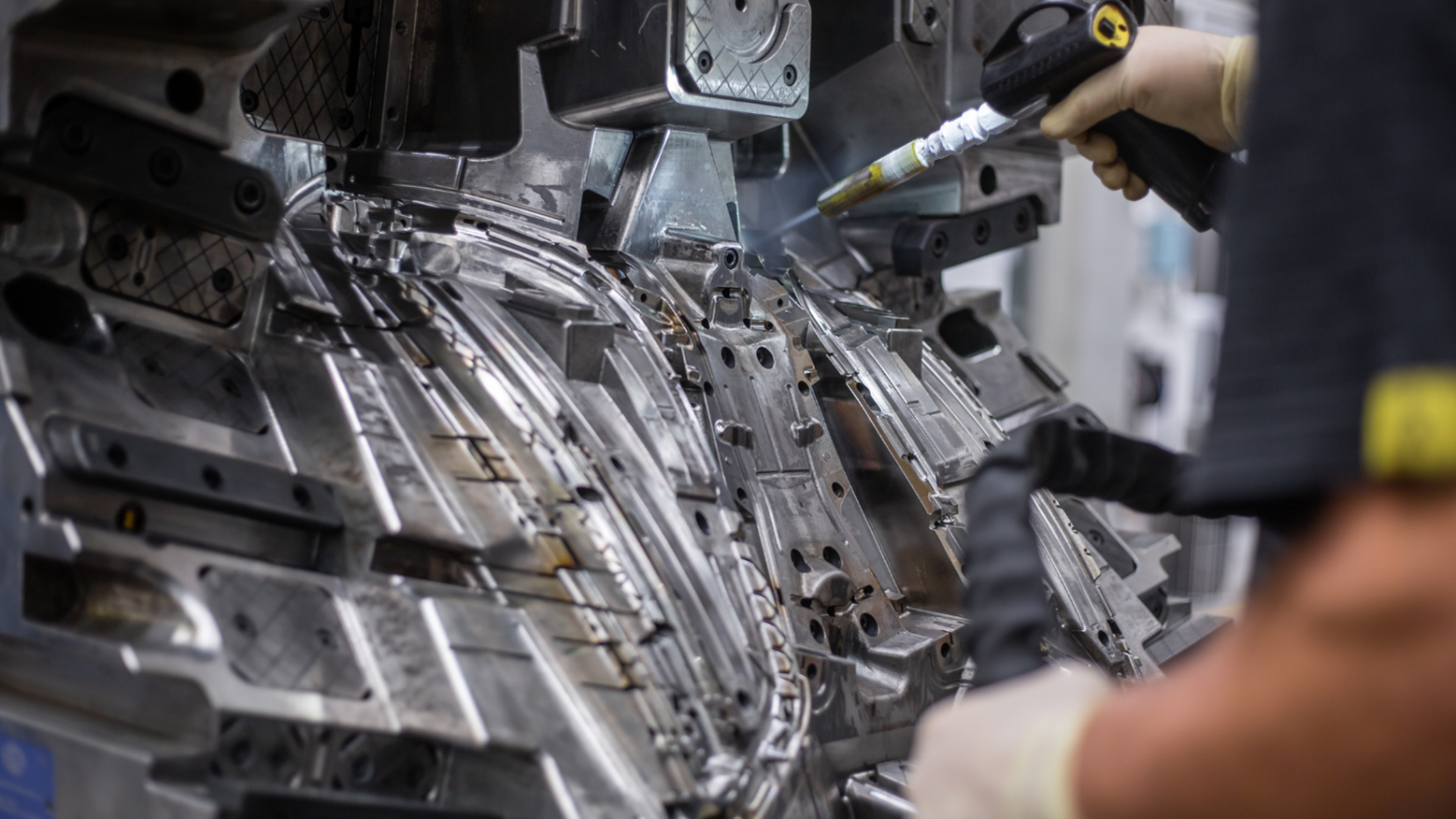

The Mold: Think of the mold as the costume designer; it shapes the plastic into the desired form.

The Plastic Material: The raw material, typically in the form of pellets, is the very essence of your future product.

The Operator: Skilled individuals who set up, monitor, and troubleshoot the process of plastic injection molding in Kansas.

Chapter 3: The Script – Plastic Injection Molding in Kansas: The Process

Imagine you’re at a theater, and the curtains rise. Here’s how the injection molding process unfolds:

Mold Setup

Before the show begins, the mold is prepared. This includes clamping the two halves of the mold (the stationary side and the movable side) together. The mold also needs to be cooled, as temperature control is crucial throughout the process.

Material Loading

The plastic material, in the form of pellets, is loaded into the machine’s hopper. From here, it’s gravity-fed into a heated barrel.

Melting and Injection – A Key Part of Plastic Injection Molding Services in Kansas

Inside the barrel, the plastic pellets are subjected to heat and pressure. This transforms them into a molten state. Once ready, a screw mechanism drives the molten plastic into the mold’s cavity. The pressure ensures the plastic fills every nook and cranny of the mold.

Cooling

As the molten plastic enters the mold, it starts to cool and solidify, taking on the mold’s shape. Cooling is a precise dance, controlled by a network of cooling channels within the mold.

Ejection

Once the plastic has cooled and solidified, it’s time for the big reveal. The mold opens, and the newly formed plastic part is ejected. This ejection can be assisted by ejector pins or air pressure.

Post-Processing

Sometimes during plastic injection molding in Kansas, the freshly molded part needs a bit of polishing or trimming. This can involve removing excess material or fine-tuning the part’s appearance.

Chapter 4: The Drama Unfolds – The Challenges and Considerations of Plastic Injection Molding Services in Kansas

Like any great performance, plastic injection molding comes with its share of challenges and considerations:

Material Selection

Choosing the right plastic material is paramount for plastic injection molding in Kansas. Factors like durability, flexibility, and heat resistance must align with the product’s intended use.

Mold Design

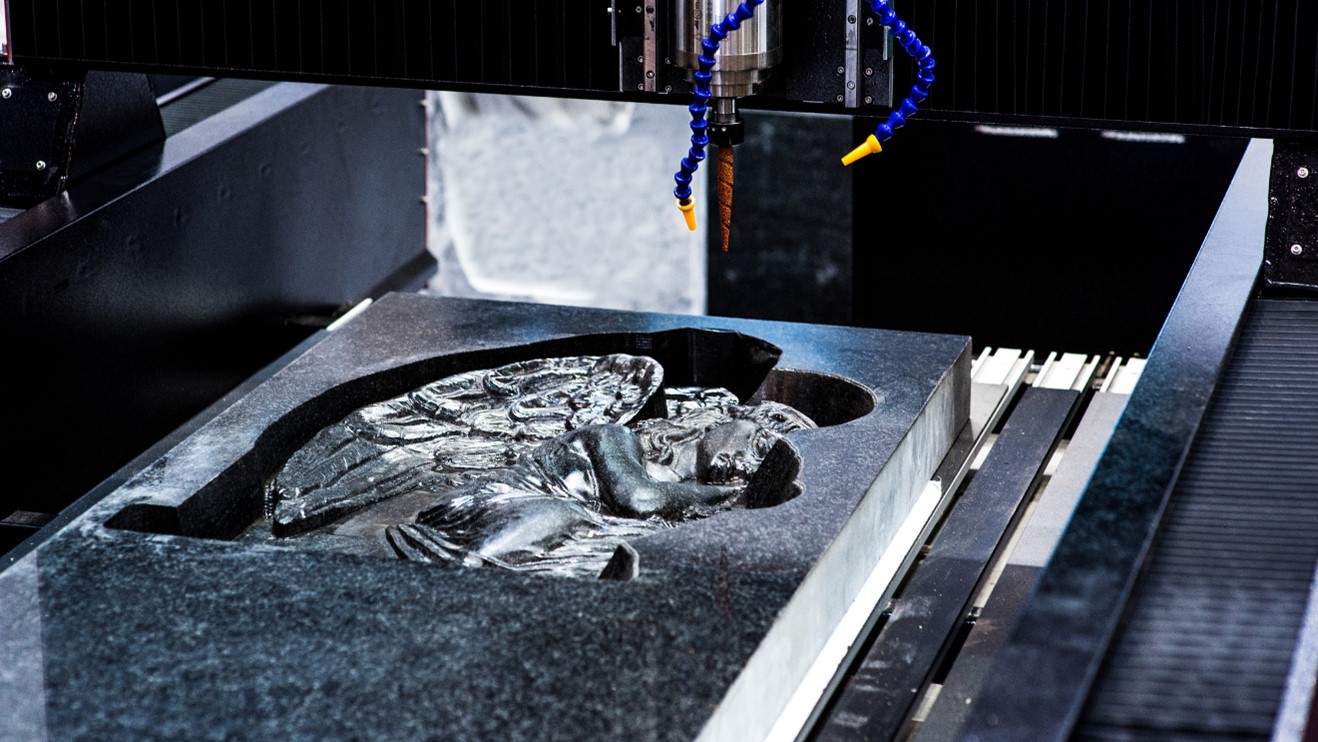

The mold design determines the part’s quality. It’s a delicate art, considering factors like part geometry, cooling efficiency, and ease of ejection.

Quality Control

Precision is the name of the game when it comes to plastic injection molding services in Kansas. Quality control measures ensure that each part meets the desired specifications, with no defects or imperfections.

Environmental Impact

Plastic waste is a concern. Many injection molding companies, like LeVic Plastics, are taking steps to reduce their environmental footprint by recycling and using eco-friendly materials.

Production Volume for Plastic Injection Molding Services in Kansas

The production volume can range from a few pieces to millions. Tooling costs and cycle times play a significant role in deciding the most cost-effective production strategy.

Chapter 5: The Grand Finale – Industries and Applications

The plastic injection molding industry is a versatile performer, catering to various sectors and applications:

Automotive

From intricate interior components to durable exterior parts, the automotive industry relies heavily on plastic injection molding services in Kansas for its production needs.

Medical Devices

Critical medical devices require precision and reliability, making plastic injection molding a trusted choice for manufacturing components like syringes, IV connectors, and surgical instruments.

Consumer Goods

From toys and household appliances to packaging materials, consumer goods come in all shapes and sizes thanks to plastic injection molding.

Electronics

Precision and compactness are vital in electronics. Injection molding helps create custom enclosures, connectors, and components.

Aerospace

Aerospace applications demand lightweight yet durable parts, making plastic injection molding services in Kansas a key player in the production of aircraft components.

Chapter 6: The Standing Ovation – LeVic Plastics

Our team at LeVic Plastics deserves the spotlight for our excellence in plastic injection molding. As a reputable company for plastic injection molding in Kansas, LeVic brings years of experience, cutting-edge technology, and a commitment to quality to the stage. Our services encompass:

Prototyping: For those seeking to test their designs before full-scale production.

Custom Mold Design: Crafting molds that ensure precision and efficiency.

Production: Offering high-volume production capabilities with strict quality control.

Material Expertise: Knowledgeable in a wide range of plastic materials, helping clients choose the perfect fit for their needs.

Sustainability: Implementing environmentally responsible practices in their operations.

Customer Collaboration: Working closely with clients to turn their visions into reality.

Chapter 7: The Curtain Falls – Conclusion

And so, our journey through the fascinating world of plastic injection molding services in Kansas comes to an end. It’s a process that combines art and science, innovation and precision, to bring everyday items and intricate components to life. LeVic Plastics, with its dedication to quality and sustainability, is a shining example of excellence in the field.

The next time you pick up a plastic object, we have a job for you. Take a moment to appreciate the intricate process that brought it into existence. It’s a testament to human ingenuity and the marvel of modern manufacturing.

Are you searching for top-notch injection molding services in Kansas? Look no further than LeVic Plastics. Our team of injection molding professionals provide the best quality and fastest production run possible. We offer EDM machining in Kansas, CNC machining, and other tooling services to ensure your project is completed properly and on time. At LeVic Plastics, we have the staff, expertise, and equipment to assist with your next project.

From large-scale orders to limited production runs in Kansas, our LeVic team will complete your order with the utmost service, quality, and efficiency. We are located just outside the KC area in Grandview, MO, and would love to assist with your next project.

We specialize in numerous production methods. If you need injection molding, CNC machining in Kansas, or one of our other tooling services in Kansas, we can help! We’ll work closely with you to find the best option for your next production run.

To contact our friendly LeVic team, call (800) 231-1232 or click here to get a free quote.

We look forward to hearing from you soon!