5 Items a Shop Must Have for Plastic Injection Molding in Kansas

Running a successful plastic injection molding shop in Kansas requires a range of essential items to ensure smooth operations and high-quality output. From machinery and molds to auxiliary equipment and safety tools, this article will outline the must-have items for any shop specializing in plastic injection molding in Kansas.

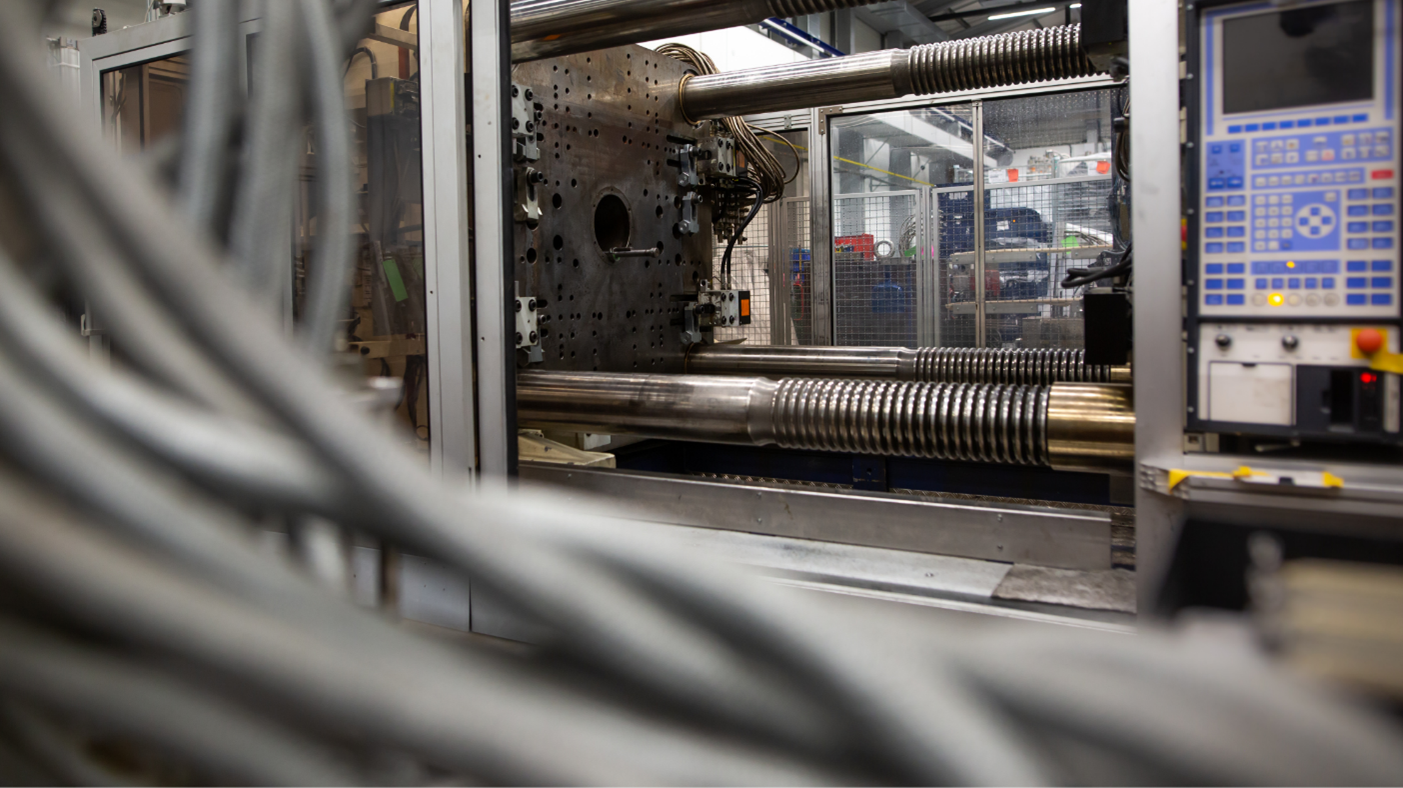

Injection Molding Machines; the Most Important Component of Plastic Injection Molding in Kansas

The heart of any shop that is centered around plastic injection molding in Kansas is the injection molding machines. These machines use high-pressure to inject molten plastic material into a mold, creating precise and intricate parts.

Selecting the right machines with appropriate tonnage, shot size, and clamping force is crucial to meet the production demands. Options like electric, hydraulic, and hybrid machines should be considered based on factors such as energy efficiency, cycle time, and cost-effectiveness.

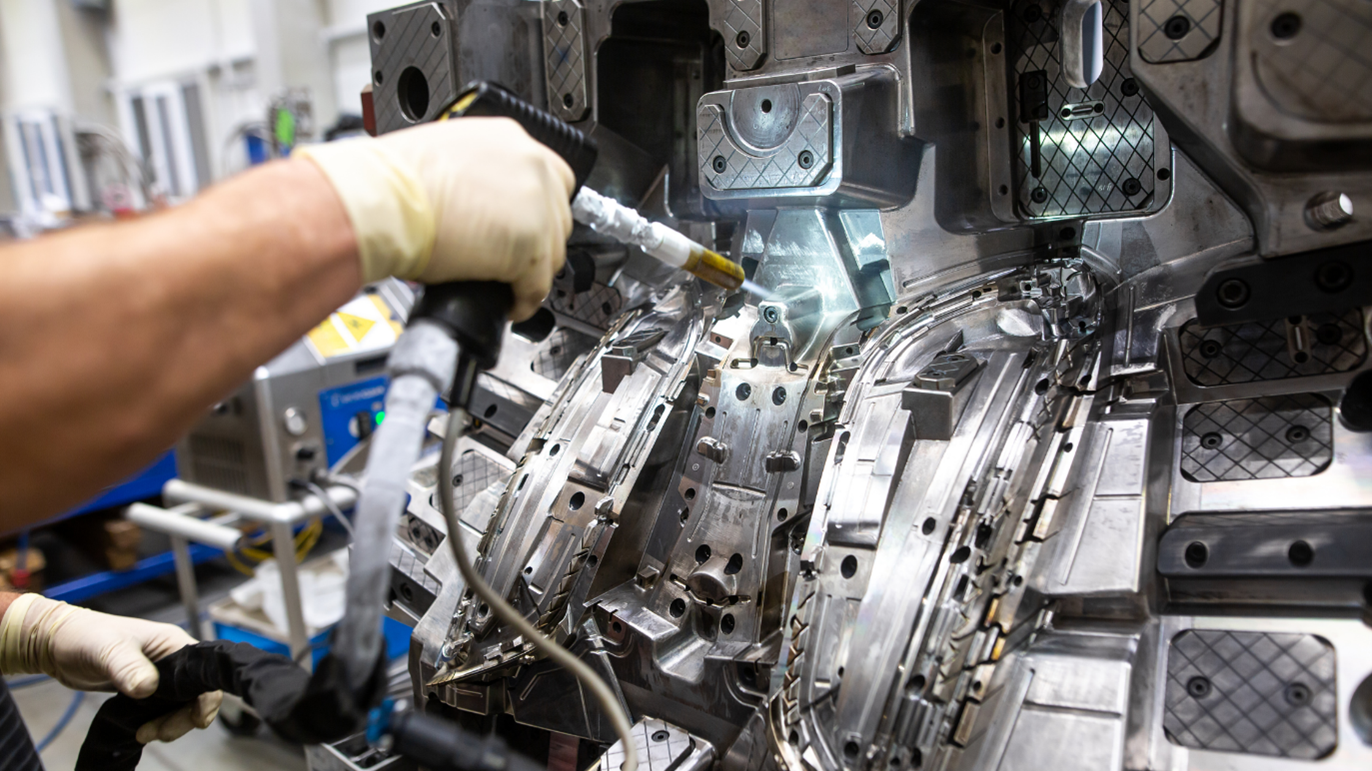

Quality Molds Are a Necessity for Plastic Injection Molding in Kansas

Top-notch molds are indispensable for producing accurate and consistent plastic parts. The molds are custom-made to fit the specific design requirements and are typically crafted from high-quality materials like steel or aluminum.

Collaborating with reputable mold manufacturers who have expertise in creating intricate designs can help ensure optimal results. Regular maintenance and repairs are also essential to prolong the lifespan of molds and maintain the quality of the produced parts.

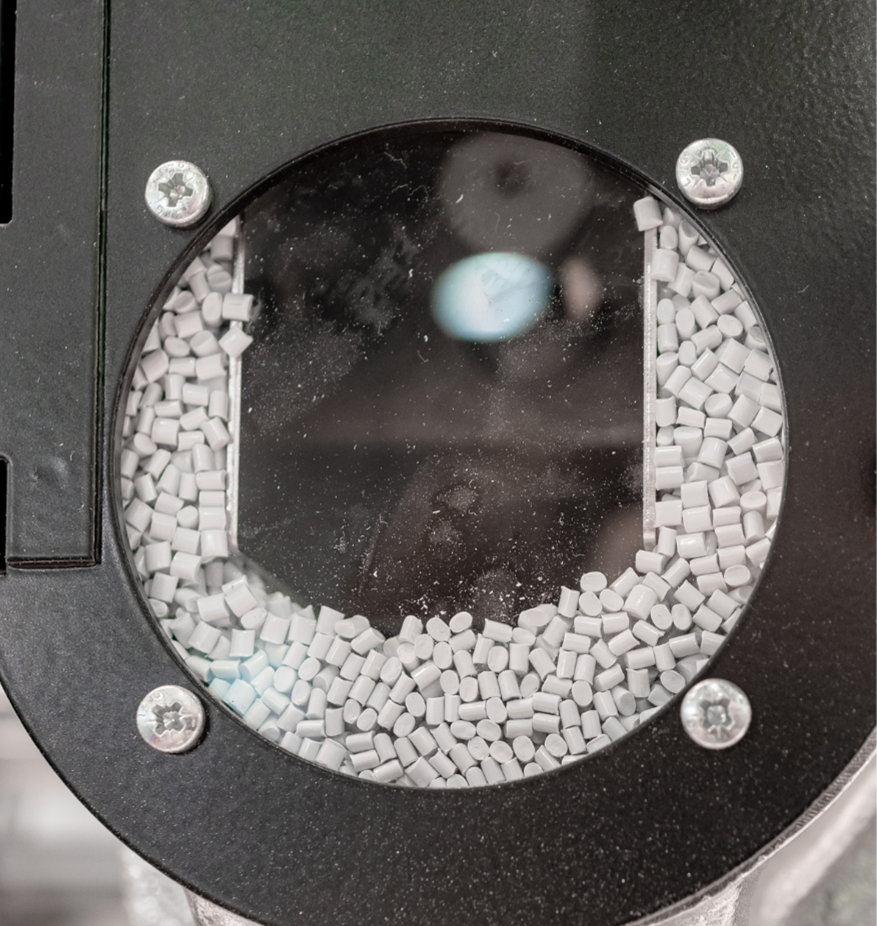

Kansas Plastic Injection Molding Companies Need High-Quality Auxiliary Equipment

In addition to injection molding machines and molds, various auxiliary equipment is necessary to support the molding process. These include material handling equipment like hoppers and loaders, temperature controllers to regulate mold and material temperatures, granulators for recycling scrap plastic, and dryers to remove moisture from raw materials.

The selection of auxiliary equipment should align with the specific production requirements of the shop to enhance efficiency, minimize waste, and maximize productivity. Any business focused on high-quality plastic injection molding in Kansas should seriously consider choosing the best auxiliary equipment possible.

Plastic Injection Molding in Kansas Would Be Northing Without Quality Control Tools

Maintaining consistent quality is vital for any plastic injection molding shop. Quality control tools such as calipers, micrometers, and gauges are essential for measuring and inspecting the dimensions and tolerances of the molded parts. Additionally, color spectrophotometers can ensure accurate color matching, while moisture analyzers help monitor and control material moisture content. Implementing a comprehensive quality control process ensures that every part meets the specified standards and customer expectations.

Kansas Plastic Injection Molding Companies Take Safety Equipment Very Seriously

Safety should be a top priority in any manufacturing environment, including plastic injection molding shops. Proper safety equipment, such as safety glasses, gloves, and ear protection, must be provided to the employees to protect them from potential hazards.

Fire extinguishers, emergency eyewash stations, and proper ventilation systems are critical for maintaining a safe working environment. Adequate training programs and protocols should be in place to educate employees about safety procedures and promote a culture of safety awareness when partaking in plastic injection molding in Kansas.

Well-equipped shops that focus on plastic injection molding in Kansas require a range of must-have items to ensure efficient production and high-quality output. From injection molding machines and molds to auxiliary equipment, quality control tools, and safety equipment, each component plays a vital role in achieving success and customer satisfaction. Investing in these essential items will set the foundation to be one of the top Kansas plastic injection molding companies.

Are you searching for top-notch injection molding services in Kansas? Look no further than LeVic Plastics. Our team of injection molding professionals provide the best quality and fastest production run possible. We offer EDM machining in Kansas, CNC machining, and other tooling services to ensure your project is completed properly and on time. At LeVic Plastics, we have the staff, expertise, and equipment to assist with your next project.

From large-scale orders to limited production runs in Kansas, our LeVic team will complete your order with the utmost service, quality, and efficiency. We are located just outside the Kansas City area in Grandview, MO, and would love the opportunity to assist with your next project.

We specialize in numerous production methods, including injection molding, CNC machining in Kansas, and other tooling services in Kansas. We’ll work closely with you to find the best option for your next production run.

To get started, call (800) 231-1232 or click here to get a free quote.

We look forward to hearing from you soon!