4 Common Terms Used for Plastic Mold Manufacturing in Missouri – At LeVic Plastics, we don’t expect our clients to be experts in the world of Missouri plastic mold manufacturing – that’s our job. In fact, there are plenty of terms we use for plastics manufacturing that most people are unfamiliar with.

In this blog, we’ll list some of the most commonly used terms used for plastic mold manufacturing in Missouri. This info could come in handy for your next production run.

What is “The Mold” When Discussing Plastic Mold Manufacturing in Missouri?

Mold isn’t just a term for that nasty green stuff that grows on old food or in areas with excess moisture. The mold is possibly the most critical piece of the plastic manufacturing process. Molds are hollow in shape so that plastic resin can be injected into them to create the desired part.

Each mold requires precision designing to ensure the part is made to the exact specifications the customer needs. Engineers and manufacturers will work diligently to ensure that the measurements of each mold are precise before beginning a Missouri plastic mold manufacturing project.

What is “Insert Molding” When Discussing Plastic Mold Manufacturing in Missouri?

The process of injection plastic resin into a mold with a metal insert is referred to as insert molding. The end result of insert molding services in Missouri is a single plastic part with a metal insert that is completely surrounded by plastic.

Insert molding can be used for various applications, including filters, insert molded couplings, threaded fasteners, and much more. Overall, insert molding services are most widely used for heavy machinery and several other industrial applications.

What is “Flash” During Plastic Mold Manufacturing in Missouri?

During production there are hiccups that can occasionally take place. One of the most common is excess “flash” or “Burrs.” This occurs when some of the molten resin escapes the mold cavity. When the molten resin escapes, it is typically along the ejector pin.

Flashes can also occur when over-injection, excessively high injection speed, and degraded molds take place. Excessive heat can also lead to burrs or flashes, so monitoring the temperature is very important for all aspects of plastic mold manufacturing.

How is the “Hopper” Used for Plastic Mold Manufacturing in Missouri?

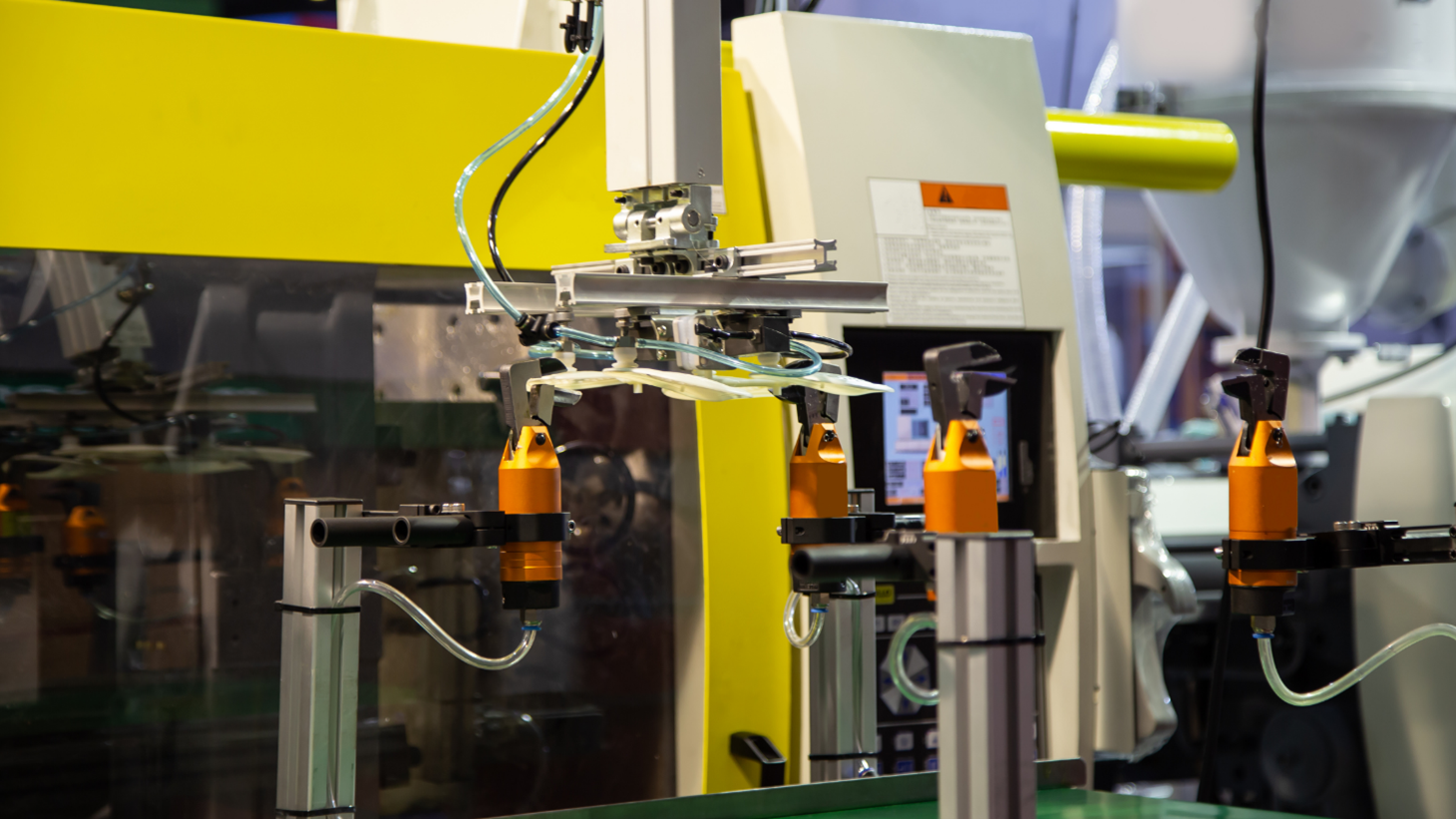

A hopper is an extremely important tool that is used for plastic mold manufacturing and injection molding. The hopper is used to store the plastic resins before they are used for the molding process.

There are different units that are added to the hopper in order to keep the properties of the resin intact. Nylon and ABS require a dryer unit to ensure the integrity of the material. The dryer unit keeps all moisture out of the plastic resin to make sure it meets the required standards. In some cases, small magnets are inserted into the hopper to remove all magnetic impurities.

Do You Need Help with Your Next Project?

Contact LeVic Plastics Today!

At LeVic Plastics, we have the staff, expertise, and equipment to assist with your next project. From large-scale orders to limited production runs in Missouri, our LeVic team will complete your order with the utmost service, quality, and efficiency. We are located just outside the Kansas City area in Grandview, MO, and would love the opportunity to assist with your next project.

We specialize in numerous production methods, including injection molding, EDM machining in Missouri, and CNC machining in Missouri. We’ll work closely with you to find the best option for your next production run.

To get started, call (800) 231-1232 or click here to get a free quote. We look forward to hearing from you soon!