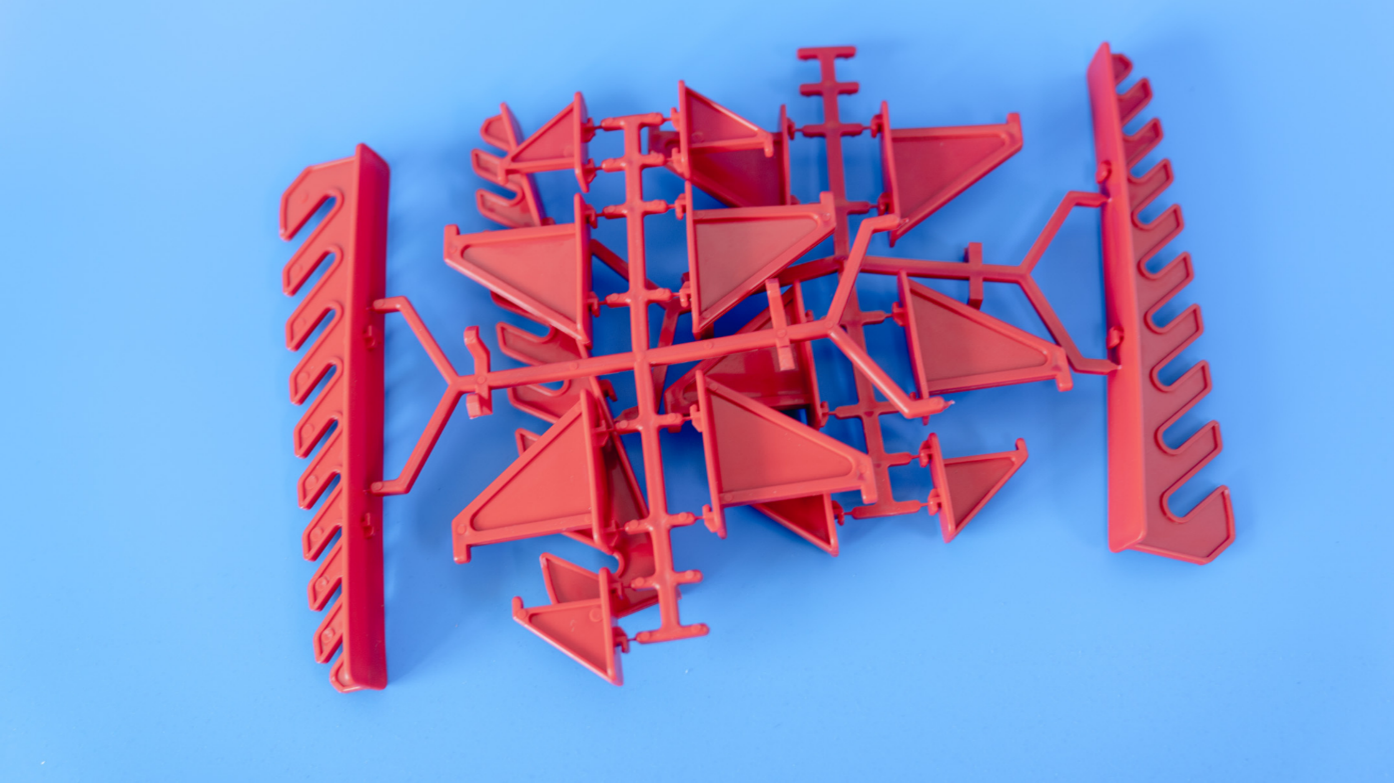

In order to have a successful company that focuses on injection molding assembly in Missouri, that company must use high-quality materials for the parts. At LeVic Plastics, we use high-grade plastics to ensure that each project is done with the utmost quality and precision.

There are a wide variety of plastics that companies will use for custom plastic injection molding in Missouri. This article will list some of the most popular injection mold plastics and a little bit of information about each one.

Acrylic

Acrylic is widely known for its strength, durability, and ability to withstand significant loads. This particular plastic does not absorb odors, so keep that in mind if you choose acrylic for your next project involving plastic injection molding services in Missouri.

Acrylonitrile Butadiene Styrene

This thermoplastic has one of the lowest melting grades when compared to other plastics. A lower melting grade means that ABS is easier to mold than other similar plastics. ABS can support different colorants and comes in different finishes and textures.

Nylon Polyamide

Polyamides can be both natural and synthetic, but nylon polyamides are always made of synthetic materials. Nylon polyamides are considered to be one of the more difficult plastics to work with because they have the tendency to shrink, which can cause inconsistent results.

Polyethylene

One of the most popular plastics used for injection molding assembly in Missouri is polyethylene. It comes in three different types:

- Low Density

- High Density

- Polyethylene Terephthalate

This plastic is selected based on its density, mainly because density controls other material properties. Polyethylene is typically a lower-cost plastic that is both water and chemical-resistant.

Polypropylene

Although it is very similar to polyethylene, polypropylene is a harder material and more heat-resistant. It is still one of the most popular plastics used for custom plastic injection molding in Missouri, mainly because it does well at keeping its shape and it is very chemical-resistant.

Polyoxymethylene

Also known to many as acetal, polyoxymethylene is used for insert molding services in Missouri that require a low amount of friction. Acetal is also used for projects which consist of parts that need high stiffness and well-rounded dimensional stability.

Polystyrene

There are two types of polystyrene used for plastic injection molding projects. They are general purpose polystyrene and high impact polystyrene. Both of these plastics are a great choice for injection molding because manufacturers know what the plastic will shrink during production. The amount of shrinkage is very consistent, so manufacturers know how to adapt or adjust to make each part the correct size and shape.

Polycarbonate

This strong and tough plastic can maintain its strength even when exposed to a wide range of temperatures. Polycarbonate’s strength is truly what it is known for, as it is estimated to be more than 250 times stronger than glass. It’s no wonder that it is one of the most common plastics used for custom injection molding in Missouri.

If you need a longtime trusted company in the Kansas City area for your next plastics project, contact LeVic Plastics today. You can reach us at (800) 231-1232, or you can contact us online to receive a free quote.