At LeVic Plastics, we use different techniques to help create the highest quality parts and products for our customers. Although we are widely known for custom injection molding, we use two other popular methods for certain projects; EDM machining and CNC machining in Kansas City.

In this article, we’ll explain the biggest differences between CNC machining and EDM machining in Kansas City, so that you can have a better idea of what types of projects each method is best suited for. We’ll provide some other information about each method that you may find helpful.

EDM Machining

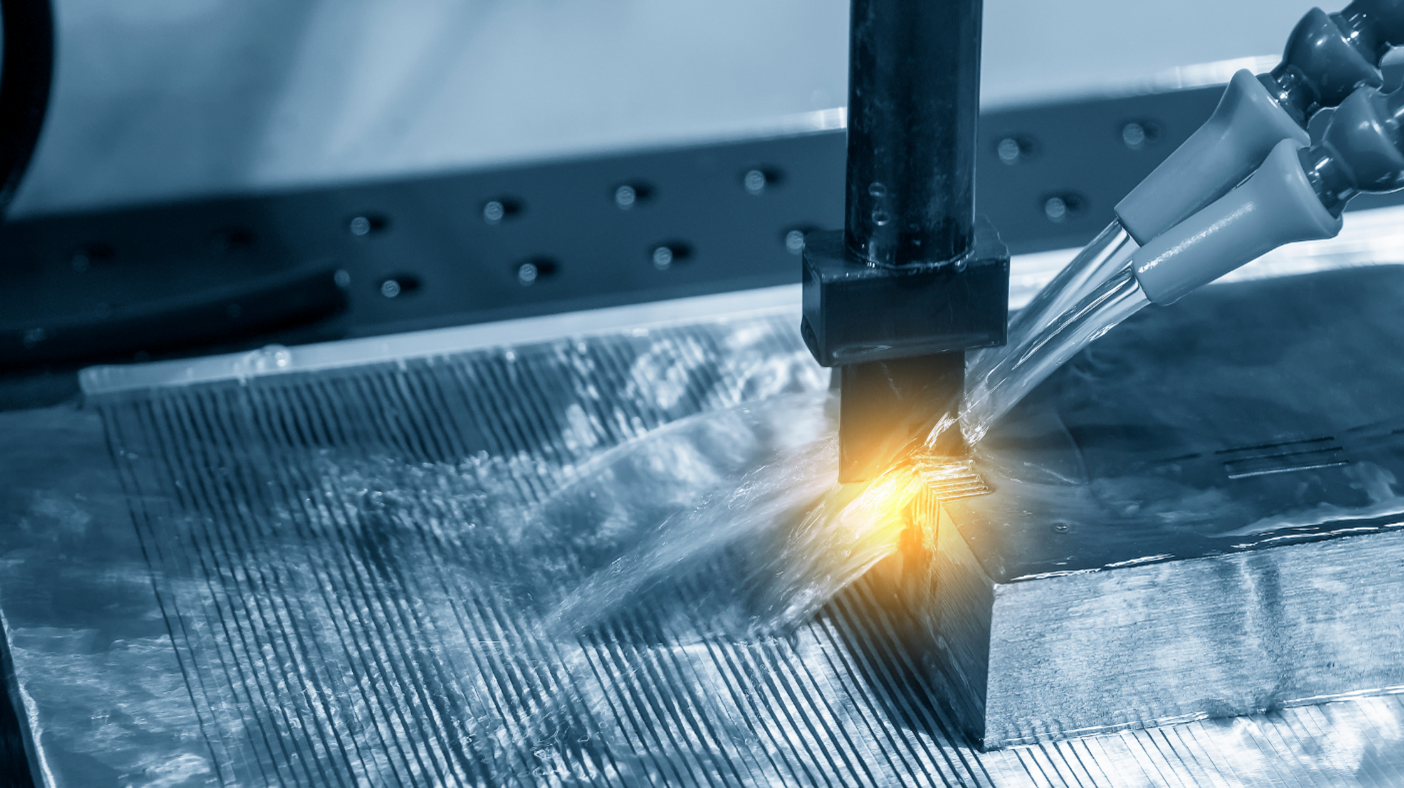

EDM stands for Electrical Discharge Machining. Other common names for this method are spark machining or arc machining. The basic process of EDM machining in Missouri involves using an electrical current to pass through an electrode and a workpiece that is separated by liquid. The electrode creates a spark, which helps form the workpiece into its final shape.

EDM Benefits

If your workpiece needs to be configured into a very complex shape, then EDM machining in Kansas City is the best method to use. When you use EDM, you will get very effective and refined milling. The entire process does not place a lot of stress on the workpiece, so if you are working with very light, delicate, and fragile materials, EDM machining is an excellent option to consider.

CNC Machining

CNC is short for Computer Numerical Control Machining. By using controlled computers, workpieces can be milled into the desired shape and size. This technology has made a significant impact on numerous businesses. CNC machining in Kansas City is a key part of why many companies are now able to produce more parts, products, and equipment at a much faster rate than they could by using previous methods.

CNC Benefits

The equipment for CNC machining in Missouri looks very similar to the equipment used for EDM machining. The biggest difference is that the CNC equipment is all controlled by computers. The CNC mill has a cutting tool that moves in multiple dimensions and will cut or polish pieces to the setting that is put in place on the computer.

The computer controls the cutting tool, cutting block, and makes the necessary turns and adjustments to get the final result. Overall, the biggest benefit of CNC machining is that no human operator is needed, so it significantly reduces a company’s labor costs, risk of accidents, and eliminates any possible injuries.

One of the most important things to do when deciding between EDM machining and CNC machining is allow yourself time to do some research. There are benefits to each method, so make sure you have considered all the factors and then make an educated decision.

If you are still not sure which is best, contact the experts at LeVic Plastics. With our extensive knowledge of production methods like EDM machining, CNC machining, and injection molding assembly in Missouri, we’ll be able to answer any questions you have regarding your next production run.

Contact us online today to get a quote on your project, or you can call us at (800) 231-1232. We look forward to working with you soon!