CNC Machining in Missouri: 26 Commonly Used Terms from A to Z — Missouri, often referred to as the “Show-Me State,” has a thriving manufacturing industry. CNC (Computer Numerical Control) machining plays a pivotal role in it. Whether you’re a seasoned professional or a curious novice when it comes to CNC machining in Missouri, understanding the terminology is crucial.

In this blog, our team at LeVic Plastics will explore CNC machining terms from A to Z. We’ll offer valuable insights into the world of precision CNC machining in Kansas City and throughout Missouri.

A – Automation:

CNC machining in Missouri leverages automation to increase productivity and consistency. Automated systems handle tasks like tool changes and material loading, reducing the need for manual intervention.

B – Ball Screw:

A critical component of CNC machining in Missouri, the ball screw converts rotary motion into linear motion, ensuring precise movement of the cutting tool.

C – Chip Control:

Effective chip control is essential to maintain the quality of CNC-machined parts. In Missouri, manufacturers employ various methods to manage and remove chips generated during the machining process.

D – Die Casting:

Often used in conjunction with CNC machining in Missouri, die casting produces complex metal parts that can then be further refined using CNC techniques.

E – Endmill:

An endmill is a cutting tool with distinct edges used for milling operations. Missouri CNC machinists rely on endmills to shape and finish parts.

F – Feeds and Speeds:

Optimizing feeds and speeds is crucial for achieving the desired surface finish and prolonging tool life for CNC machining in Kansas City and throughout the Show Me State. Missouri shops calculate these parameters.

G – G-Code:

G-Code is the language CNC machines understand. It contains instructions for tool movement, speed, and other machining operations.

H – Horizontal Machining Center (HMC):

These CNC machines in Missouri have a horizontal spindle orientation, making them ideal for applications requiring heavy material removal.

I – Inspection:

Quality control is paramount for CNC machining in Missouri. Inspection involves measuring and verifying the accuracy of machined parts to meet strict tolerances. At LeVic Plastics, we follow strict inspection guidelines to ensure that every project is completed with the utmost detail.

J – Jig:

A fixture or jig is used to hold workpieces securely during machining, ensuring consistent and precise results in Missouri CNC shops.

K – Keyway:

A keyway is a slot or groove machined into a part to accept a key, which ensures proper alignment or rotation of components. CNC machines in Missouri create keyways with precision.

L – Lathe:

CNC lathes are indispensable when it comes to CNC machining in Missouri, especially for turning cylindrical parts. They rotate workpieces while a cutting tool shapes them.

M – Missouri:

The state itself is a significant hub for CNC machining, housing numerous machining facilities and skilled professionals. LeVic Plastics is proud to conduct business with many wonderful companies and individuals throughout the state of Missouri.

N – Non-Ferrous Metals:

CNC machining in Missouri processes various materials, including non-ferrous metals like aluminum, brass, and copper, which are prized for their corrosion resistance and lightweight properties.

O – Operator:

Skilled operators for CNC machining in Kansas City and throughout Missouri are responsible for setting up machines, loading materials, and monitoring the machining process to ensure quality and efficiency.

P – Prototyping:

CNC machining in Missouri is invaluable for creating prototypes of new products, allowing manufacturers to refine designs before full-scale production.

Q – Quick Change Tooling:

Missouri CNC shops like LeVic Plastics employ quick change tooling systems to reduce setup time and increase productivity.

R – Rapid Prototyping:

CNC machining in Missouri enables rapid prototyping, facilitating swift development and testing of new concepts and products.

S – Swiss Machining:

This precision machining technique is popular in Missouri for producing small, intricate parts with tight tolerances, often used in medical and aerospace applications.

T – Tolerance:

CNC machining in Missouri demands strict adherence to specified tolerances, ensuring parts fit together precisely as intended.

U – Ultrasonic Machining:

An advanced machining process used in Missouri for brittle materials, where ultrasonic vibrations assist in material removal.

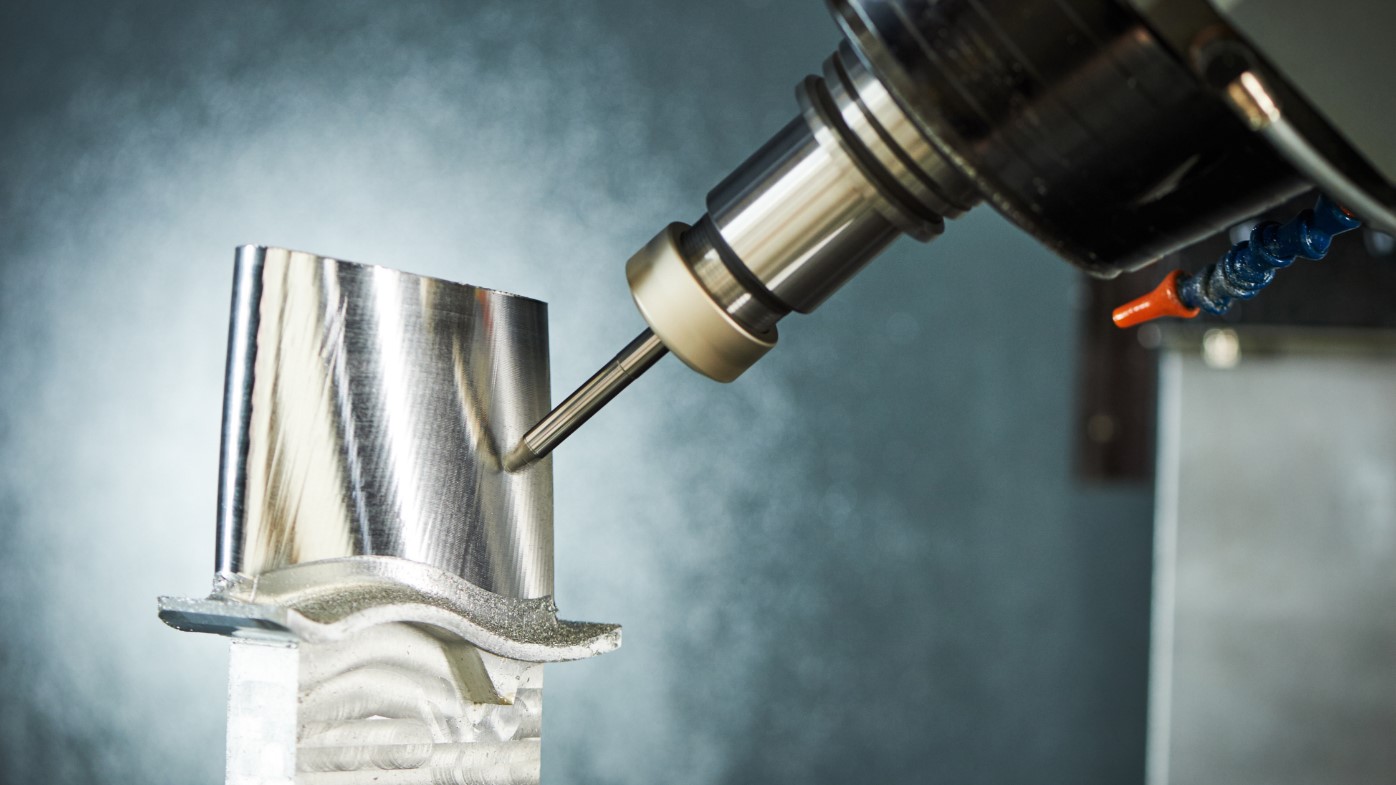

V – Vertical Machining Center (VMC):

VMCs have a vertical spindle orientation and are commonly used in Missouri for tasks that require precision and versatility.

W – Wire EDM (Electrical Discharge Machining):

In Missouri, wire EDM is employed to create complex shapes in conductive materials using electrical discharges.

X – X-Axis:

One of the primary axes of CNC machines, the X-axis controls horizontal movement, crucial for precision CNC machining in Kansas City and throughout Missouri.

Y – Y-Axis:

The Y-axis controls the vertical movement of the tool, allowing for multi-dimensional machining in Missouri’s CNC facilities.

Z – Zero Point:

The reference point from which all measurements and movements are made. Ensuring accurate zero points is fundamental in Missouri’s CNC machining processes.

As CNC machining continues to advance in Missouri, understanding these terms is essential for anyone involved in the industry. Whether you’re a manufacturer, engineer, or enthusiast, this A-to-Z glossary provides a valuable glimpse into the precision world of CNC machining in the Show-Me State.

Are you searching for top-notch injection molding services in Missouri? Look no further than LeVic Plastics. Our team of injection molding professionals provide the best quality and fastest production run possible. We offer EDM machining in Missouri, CNC machining, and other tooling services to ensure your project is completed properly and on time. At LeVic Plastics, we have the staff, expertise, and equipment to assist with your next project.

From large-scale orders to limited production runs in Missouri, our LeVic team will complete your order with the utmost service, quality, and efficiency. We are located just outside the Kansas City area in Grandview, MO, and would love the opportunity to assist with your next project.

We specialize in numerous production methods, including injection molding, CNC machining in Missouri, and other tooling services in Missouri. We’ll work closely with you to find the best option for your next production run.

To get started, call (800) 231-1232 or click here to get a free quote.

We look forward to hearing from you soon!