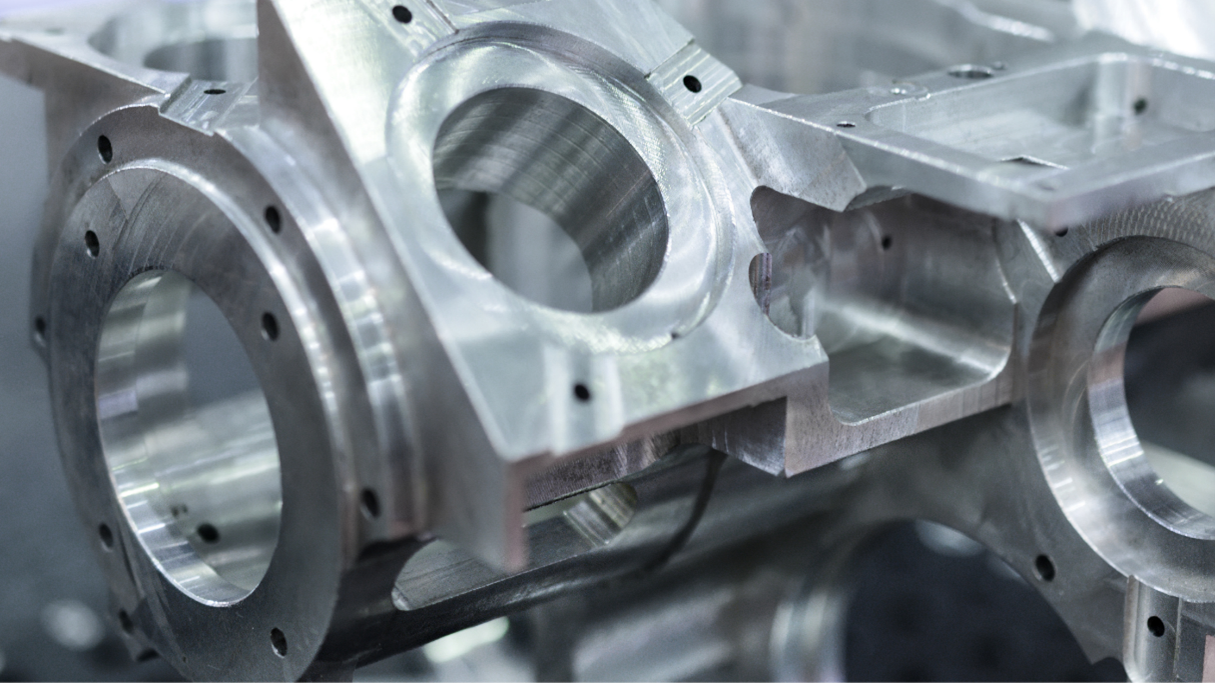

The two most common types of molds used for injection molding are steel and aluminum molds in Kansas City. Immediately when you start comparing the two options in your head, it might be easy to think that steel is the far better option.

In some ways, you would be correct; steel molds in Kansas City are very strong and tend to hold up well during large production runs. However, you should not immediately dismiss the possibility of using aluminum molds in Missouri. You may have received some bad information in the past about aluminum molds, but this article will put those negative thoughts to rest.

Here are some of the most common myths you may have heard regarding aluminum molds in Missouri.

Myth #1 – Aluminum is Only Used for Low Production Quantities

Although steel molds are typically used for the largest production runs, aluminum molds can absolutely hold their own. Many people think that aluminum is only ideal for limited production runs in Missouri; however, it is quite common for aluminum molds to have the durability to last for 100,000 plastic parts.

That sure seems like a pretty large production run. So don’t immediately rule out the possibility of using aluminum for your next large plastics project.

Myth #2 – Aluminum is Not a Good Option for Complex Designs

Complex designs are not as much about the material used to make the mold; it has more to do with the quality of the design and the manufacturing. Both of these aspects rely heavily on each other. As long as your project is in the hands of an experienced specialist for injection molding assembly in Kansas City, you should be in good hands, no matter if you use steel or aluminum molds for your project.

Myth #3 – Aluminum Molds in Kansas City Have Limited Textures

Nearly any type of finish that can be applied to steel molds can also be used for aluminum. Many people are under the impression that aluminum molds are more difficult to work with because they often include small, closed-in features that make it challenging to apply texture. If you choose to use steel molds, that’s fine; just make sure you know that aluminum molds in Missouri are still capable of providing similar textures as steel.

Myth #4 – High-Temperature Resins Can’t Be Used Successfully with Aluminum

Some of the highest temperature resins, like Ultem and Vectra, have been used successfully with aluminum molds. Highly abrasive resins require a little bit of extra care, like using hardened aluminum alloy.

Contact LeVic Plastics for Your Next Plastic Injection Molding Project

No matter if you choose aluminum or steel molds for your next production run, LeVic Plastics has you covered. Our team of experts will oversee your project and make sure all your parts or products are made with the utmost quality and care. Let us prove it to you!

Give our team a call today at (800) 231-1232, or you can contact us online to receive a free quote on your next project. We look forward to working with you!