Explaining Kansas Insert Molding Services

Insert molding is a highly efficient and versatile manufacturing process that combines injection molding and insert placement into a single operation. It involves the injection of molten material around or over pre-placed inserts, creating a strong, integrated component. This technique is widely used across various industries to enhance product performance, reduce assembly costs, and improve overall design flexibility.

Initial Processes of Kansas Insert Molding Services

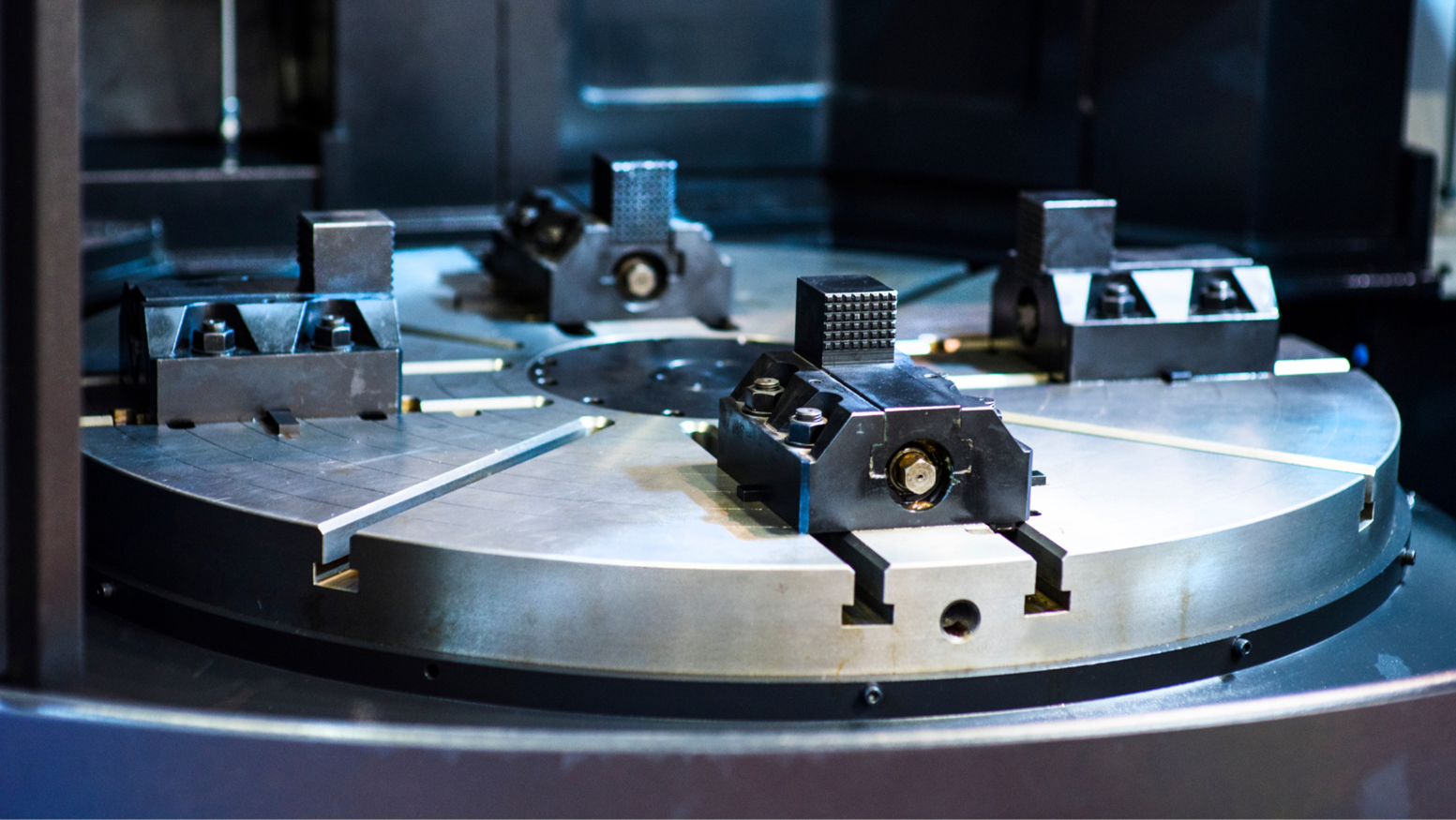

The process of Insert molding services in Kansas begins with the preparation of the inserts. Inserts can be metallic, plastic, or even electronic components that are strategically placed into the mold cavity before the injection molding cycle. These inserts serve different purposes, such as providing reinforcement, adding functionality, or enabling electrical conductivity within the finished product.

Once the inserts are in place, the mold closes, and the molten material, typically thermoplastic, is injected into the mold cavity. The material encapsulates the inserts, bonding with them during the solidification process. This creates a robust mechanical interlock between the insert and the surrounding material, ensuring secure integration.

Benefits of Kansas Insert Molding Services

One of the primary advantages of inserting molding is its ability to streamline the manufacturing process. By combining multiple steps into a single operation, it eliminates the need for secondary assembly processes, such as fastening or welding inserts. This results in reduced labor costs, shorter production cycles, and improved overall efficiency.

Insert molding services in Kansas also offer enhanced product reliability. The strong bond between the insert and the surrounding material ensures increased structural integrity, minimizing the risk of part failure or detachment. Additionally, the encapsulation of inserts protects them from environmental factors, such as corrosion or vibration, extending their lifespan and improving the durability of the final product.

Design flexibility is another key benefit of Kansas insert molding services. The technique allows for the integration of various inserts into complex shapes and geometries, enabling the creation of innovative and compact designs. It opens up new possibilities for product functionality, as inserts can be used to incorporate features like threaded inserts for assembly, electronic components for circuitry, or even decorative elements.

Financial Information About Insert Molding Services in Kansas

Furthermore, inserting molding supports cost savings through material reduction. By using inserts strategically placed only where needed, manufacturers can minimize the amount of expensive material required for the component. This optimization of material usage reduces overall material costs and contributes to a more sustainable manufacturing process.

Insert molding services in Kansas are used for applications across a wide range of industries. In the automotive sector, it is commonly used for manufacturing connectors, sensor housings, and interior components. The medical field benefits from insert molding for producing surgical instruments, catheters, and drug delivery devices. Consumer electronics leverage the technique for creating compact and robust components such as connectors, switches, and wearables.

In conclusion, Kansas insert molding services are highly efficient and combine injection molding and insert placement into a single operation. By encapsulating pre-placed inserts with molten material, it creates integrated components that offer improved strength, reliability, and design flexibility.

Kansas insert molding services streamline production, reduce assembly costs, and enable the development of innovative and compact designs. With its numerous advantages, insert molding has become a valuable manufacturing technique across various industries, contributing to the production of high-quality and cost-effective products.

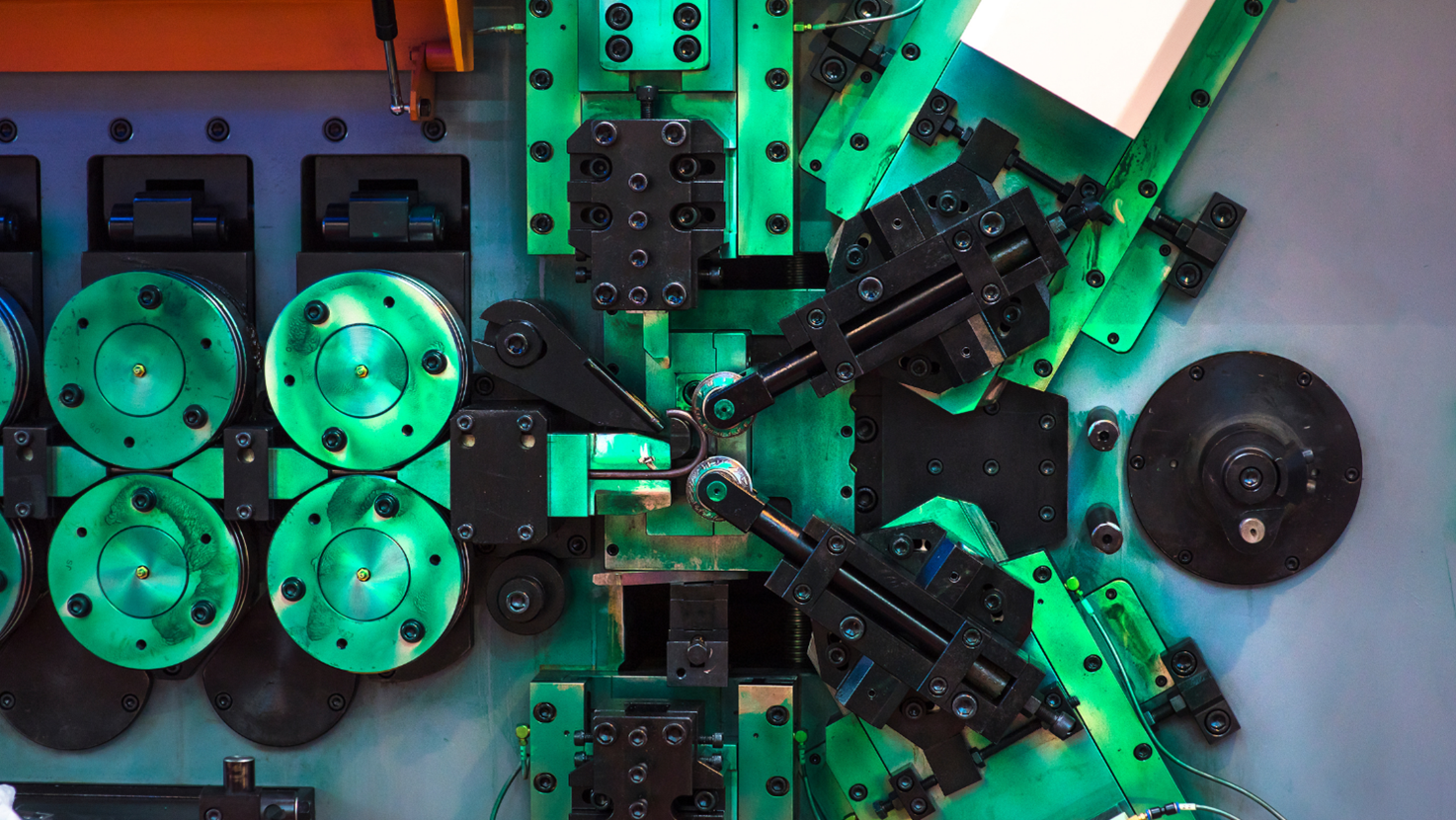

Are you searching for top-notch injection molding services in Kansas? Look no further than LeVic Plastics. Our team of injection molding professionals provide the best quality and fastest production run possible. We offer EDM machining in Kansas, CNC machining, and other tooling services to ensure your project is completed properly and on time. At LeVic Plastics, we have the staff, expertise, and equipment to assist with your next project.

From large-scale orders to limited production runs in Kansas, our LeVic team will complete your order with the utmost service, quality, and efficiency. We are located just outside the Kansas City area in Grandview, MO, and would love the opportunity to assist with your next project.

We specialize in numerous production methods, including injection molding, CNC machining in Kansas, and other tooling services in Kansas. We’ll work closely with you to find the best option for your next production run.

To get started, call (800) 231-1232 or click here to get a free quote.

We look forward to hearing from you soon!