The Evolution of Plastic Injection Molding in Kansas: 50 Years of Progress

America’s heartland is home to a tale of creativity, advancement, and tenacity. Kansas has been a leader for plastic injection molding over the past 50 years, reshaping the global manufacturing scene and supplying high-quality plastic products. This article will examine the amazing history of plastic injection molding in Kansas, tracking its development, highlighting turning points, and honoring the noteworthy advancements made throughout the years.

Pioneering Days: Laying the Foundation

The early years of plastic injection molding in Kansas were marked by determination and resourcefulness. The pioneers recognized the potential of this manufacturing technique and its ability to revolutionize industries across the board. Companies like LeVic Plastics emerged as frontrunners, investing in cutting-edge technology, and creating a strong foundation for the industry to flourish.

Technological Advancements: Empowering Precision and Efficiency

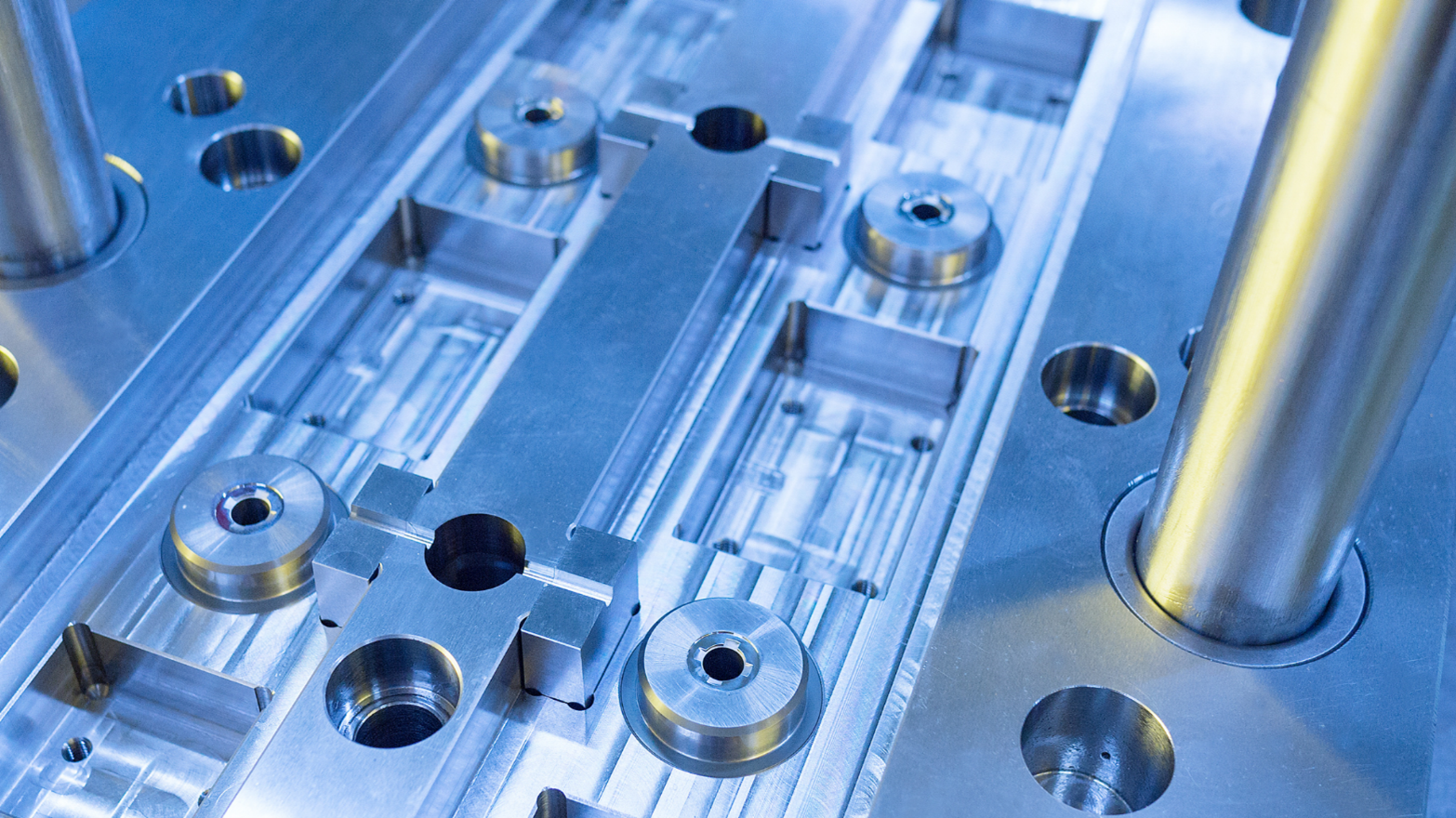

As plastic injection molding gained momentum in Kansas, technological advancements played a pivotal role in enhancing precision, productivity, and efficiency. The industry underwent a change thanks to innovations like computer-aided design (CAD), computer-aided manufacturing (CAM), and automated procedures.

These advancements allowed manufacturers to create intricate designs, streamline production processes, and reduce waste, leading to significant cost savings. By saving money on daily operations, it allowed plastic injection companies to invest in other areas of their business.

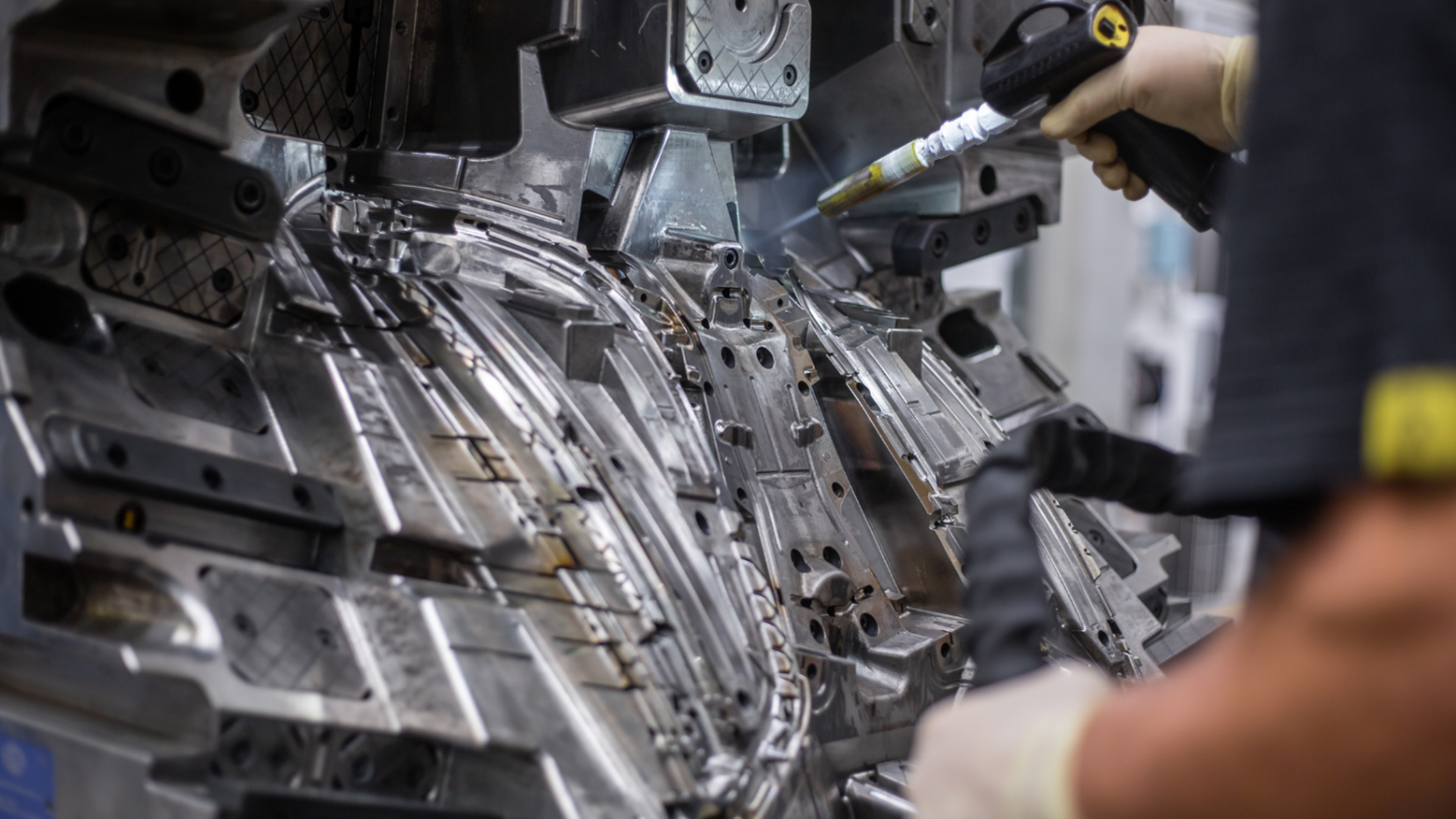

LeVic Plastics, a trailblazer in Kansas plastic injection molding, has embraced these advancements. We continuously update our equipment to stay at the forefront of the industry. The integration of robotics and automation allows us to achieve unparalleled levels of precision, speed, and consistency in our manufacturing processes.

Sustainable Solutions: Embracing Environmental Consciousness

With growing awareness of environmental issues, the plastic injection molding industry in Kansas stepped up to address sustainability challenges. LeVic Plastics and other manufacturers made significant efforts to reduce their carbon footprint and embrace more eco-friendly practices. By incorporating recycled materials, optimizing energy usage, and implementing efficient waste management systems, they minimized the environmental impact associated with plastic manufacturing.

Kansas plastic injection molding companies also actively explored bio-based and biodegradable materials, providing sustainable alternatives without compromising on quality or performance. These initiatives demonstrated the industry’s commitment to preserving the environment for future generations.

Collaborative Ecosystem: Nurturing Growth and Innovation

The collaborative ecology that has flourished throughout time is one of the major factors influencing the success of plastic injection molding in Kansas. Government agencies, business leaders, and educational institutions have joined forces to promote innovation, spread information, and promote growth.

Partnerships between plastic manufacturers and universities, for example, have resulted in groundbreaking research and development initiatives, leading to novel materials, improved manufacturing techniques, and expanded applications.

The establishment of specialized training programs and apprenticeships has also played a crucial role in nurturing a skilled workforce. These initiatives ensure that Kansas plastic injection molding companies have access to well-trained professionals who can effectively operate advanced machinery and drive continuous improvement.

Diverse Applications: Impacting Industries Across the Board

Plastic injection molding in Kansas has left an indelible mark on a wide range of industries, transforming the way products are designed, manufactured, and delivered. From automotive components to consumer goods, medical devices to electronics, the versatility of plastic injection molding has enabled businesses to achieve unprecedented levels of customization, functionality, and cost-effectiveness.

At LeVic Plastics, our extensive experience and expertise, has successfully served diverse sectors, delivering innovative solutions that meet the unique requirements of each industry. Our commitment to quality, precision, and customer satisfaction has earned them a reputation as a trusted partner for businesses around the globe.

Quality Assurance: Ensuring Excellence at Every Stage

One critical aspect that has propelled the progress of plastic injection molding in Kansas is the unwavering commitment to quality assurance. LeVic Plastics and other manufacturers understand that delivering superior products is paramount to their success and customer satisfaction.

To achieve excellence, rigorous quality control measures are implemented at every stage of the manufacturing process. Advanced inspection technologies, such as automated vision systems and coordinate measuring machines, are employed to meticulously assess the dimensional accuracy, structural integrity, and surface finish of the molded parts. This guarantees that every product satisfies or surpasses the exacting quality criteria established by the sector.

Moreover, Kansas plastic injection molding companies adhere to industry certifications and standards, such as ISO 9001, to demonstrate their commitment to quality management systems. These certifications provide assurance to customers that their products are manufactured with precision and consistency.

The journey of plastic injection molding in Kansas over the past 50 years is a testament to the spirit of innovation, collaboration, and progress. From humble beginnings to becoming a powerhouse in the manufacturing world, Kansas has consistently pushed the boundaries of what is possible with plastic injection in Kansas.

LeVic Plastics, along with other industry leaders, has played a significant role in this journey. Embracing technological advancements, sustainability practices, and fostering a collaborative ecosystem, they have elevated the standards of a plastic injection molding in Kansas and set a benchmark for the industry worldwide.

As we look to the future, Kansas will continue to be a hub of innovation and excellence in plastic injection in Kansas. The industry has a strong foundation, a skilled workforce, and a commitment to sustainable practices. Knowing this, the industry is poised for even greater achievements in the years to come.

Are you searching for top-notch injection molding services in Kansas? Look no further than LeVic Plastics. Our team of injection molding professionals provide the best quality and fastest production run possible. We offer EDM machining in Kansas, CNC machining, and other tooling services to ensure your project is completed properly and on time. At LeVic Plastics, we have the staff, expertise, and equipment to assist with your next project.

From large-scale orders to limited production runs in Kansas, our LeVic team will complete your order with the utmost service, quality, and efficiency. We are located just outside the Kansas City area in Grandview, MO, and would love the opportunity to assist with your next project.

We specialize in numerous production methods, including injection molding, CNC machining in Kansas, and other tooling services in Kansas. We’ll work closely with you to find the best option for your next production run.

To get started, call LeVic Plastics today!

OR

Click here to get a free quote.