The process of injection molding assembly in Kansas City involves creating a mold that can be used to produce plastic parts through the process of injection molding. The process of assembling an injection mold can be broken down into several steps, including design, prototyping, tooling, and production.

Getting Started With Injection Molding Assembly in Kansas City

The first step in the process of injection molding assembly in Kansas City is the design phase. This is where the part to be produced is designed and the mold is created based on the part’s design. The design of the part and mold is typically done using computer-aided design (CAD) software, which allows for detailed and accurate modeling of the part and mold.

Once the design of the part and mold is complete, a prototype of the part is typically created. This is done using a rapid prototyping process such as 3D printing or CNC machining. This allows the design to be tested and any necessary changes to be made before the tooling process begins.

The Tooling Process for Injection Molding Assembly in Kansas City

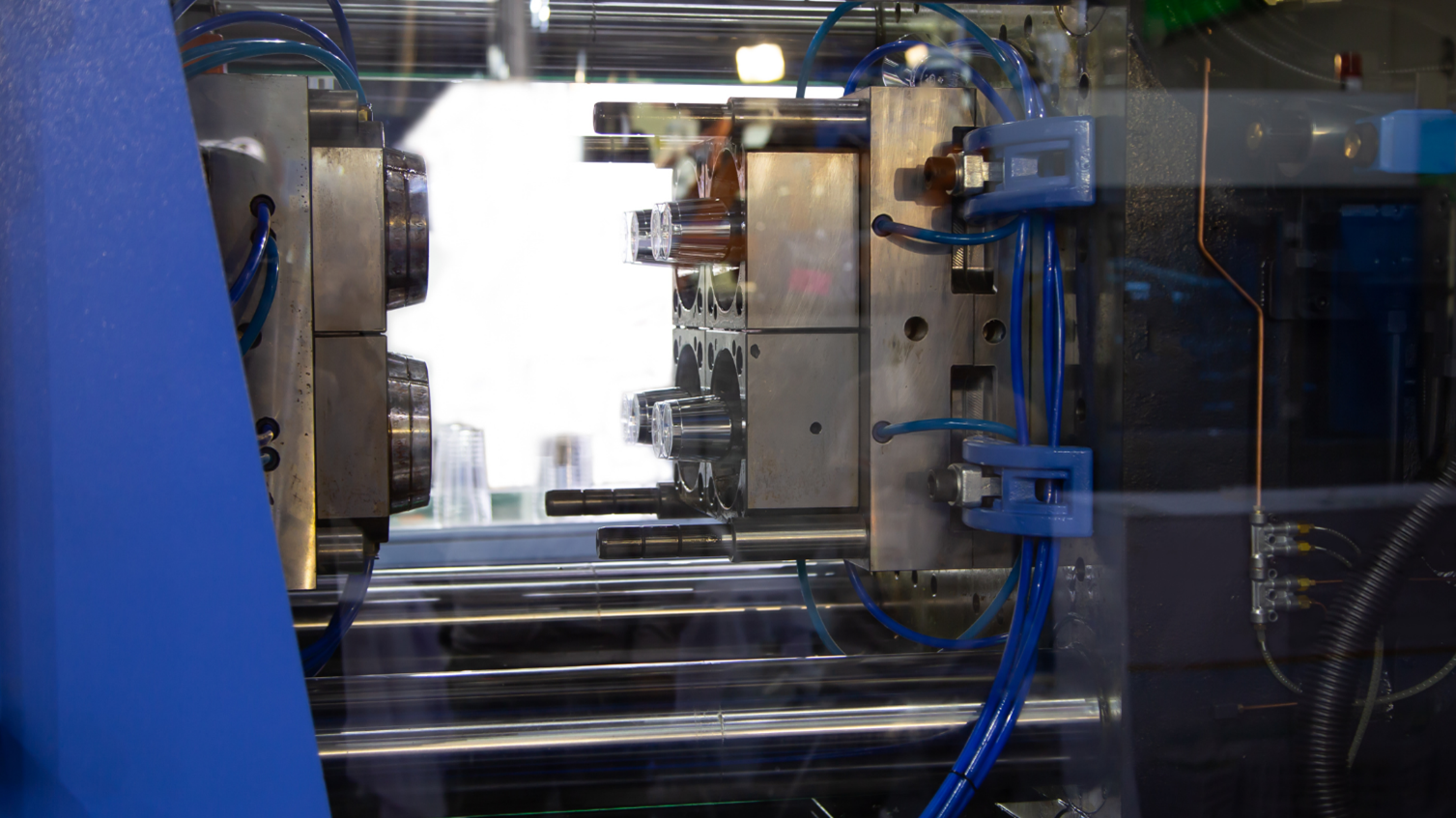

The tooling process is where the actual mold is created. This can be done using a variety of methods, such as CNC machining, EDM (electrical discharge machining), or even hand-scraping. The method used will depend on the complexity of the mold, the materials it will be made from, and the production quantities required.

Once the mold is complete, it is then prepared for production. This includes cleaning and polishing the mold, as well as installing any necessary components such as cooling lines or ejector pins.

The Production Process for Injection Molding Assembly in Kansas City

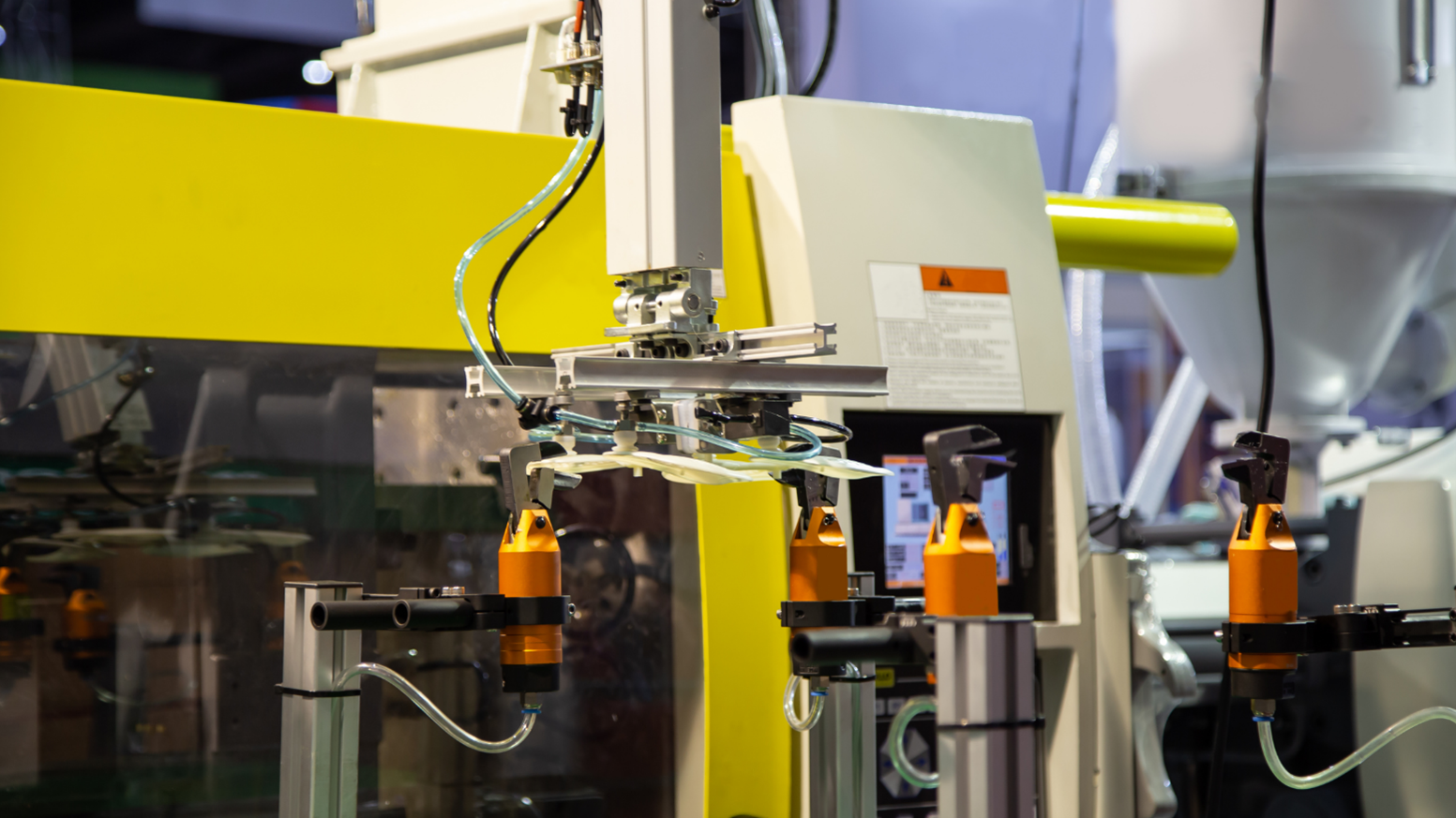

The production process begins with the injection of raw plastic material into the mold. The mold is then closed and the plastic is allowed to cool and harden. Once the plastic has hardened, the mold is opened and the part is ejected. The process is then repeated to produce more parts.

The process of injection mold assembly is a complex and detailed process that requires a high level of precision and expertise. It is important to work with a plastic injection molding company in Kansas City that has experience in injection molding and can guide you through the process. This will ensure that your parts are produced to the highest quality standards.

In summary, injection mold assembly in Kansas City is a fascinating technique. The process of creating a mold can be used to produce plastic parts through the process of injection molding. The process includes several steps: design, prototyping, tooling, and production.

The design and prototyping phase is typically done using computer-aided design software. Tooling can be done using various methods like CNC machining, EDM, or hand-scraping. Once the mold is complete, it is prepared for production, which involves injection of raw plastic material into the mold, cooling, and hardening of plastic, opening the mold, and ejecting the part.

It is a complex process that requires a high level of knowledge & experience, and it is crucial to work with an experienced plastic injection molding company in Kansas City.

Contact LeVic Plastics Today!

At LeVic Plastics, we have the staff, expertise, and equipment to assist with your next project. From large-scale orders to limited production runs in Kansas City, our LeVic team will complete your order with the utmost service, quality, and efficiency. We are located just outside the Kansas City area in Grandview, MO, and would love the opportunity to assist with your next project.

We specialize in numerous production methods, including injection molding, EDM machining in Kansas City, and other tooling services in Kansas City. We’ll work closely with you to find the best option for your next production run.

To get started, call (800) 231-1232 or click here to get a free quote. We look forward to hearing from you soon!