In the heart of America’s manufacturing landscape, where innovation and precision intersect, the world of plastic injection molding in Kansas is undergoing a transformative evolution. The state of Kansas is widely known for its robust manufacturing sector. Kansas has been a key player in shaping industries through advancements in plastic injection molding. In this blog, our LeVic Plastics team will dive deeper into the latest developments and innovations that are reshaping the landscape of plastic injection molding in the Sunflower State.

The Foundations of Plastic Injection Molding in Kansas

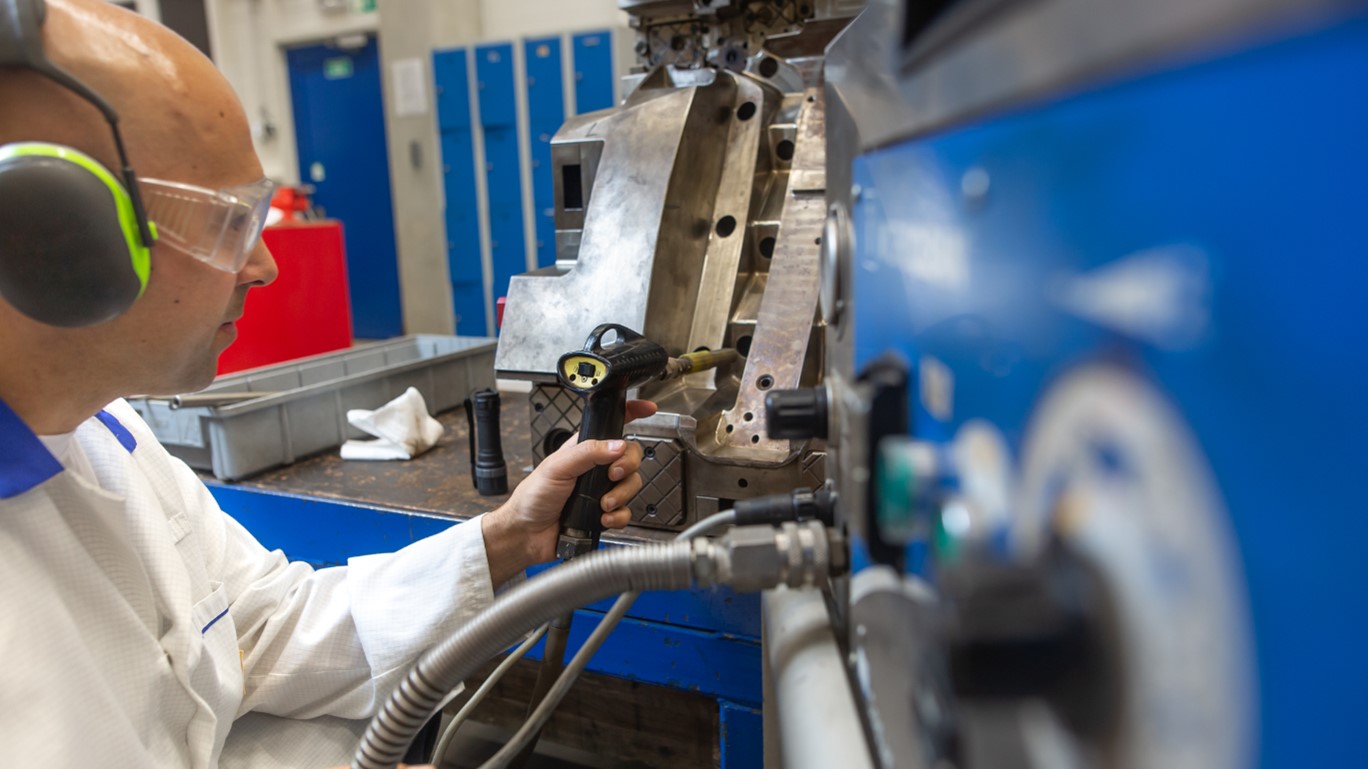

Before we explore the cutting-edge advancements, let’s revisit the foundational principles of plastic injection molding in Kansas. This widely used manufacturing process involves injecting molten plastic into a mold cavity, allowing it to cool and solidify, ultimately producing a wide range of plastic components with high precision and consistency. The process is characterized by several key steps:

Material Selection: The process begins with the selection of a suitable thermoplastic or thermosetting polymer. Factors such as material properties, durability, and intended application influence this critical decision.

Mold Design: The mold, typically made of metal, is designed to define the shape and features of the final product. It consists of two halves – the cavity and the core – and may include additional features such as runners and gates.

Injection: The chosen plastic material is heated to a molten state and injected into the mold cavity under high pressure. This ensures that the material fills every crevice of the mold, capturing intricate details and features.

Cooling and Solidification: Once injected, the molten plastic is allowed to cool and solidify within the mold. Cooling systems within the mold assist in achieving the desired properties of the final product.

Ejection: After solidification, the mold opens, and the newly formed plastic part is ejected. This marks the completion of one cycle of the injection molding process.

Innovations Shaping Plastic Injection Molding in Kansas

Advanced Materials and Composites: Kansas is witnessing a surge in the use of advanced materials and composite plastics for plastic injection molding in Kansas. Manufacturers are exploring materials with enhanced properties, such as high strength, heat resistance, and improved durability. The integration of innovative additives and reinforcements into the polymer matrix is enabling the production of components that meet the stringent requirements of diverse industries.

Fiber-Reinforced Plastics: Injection molding with fiber-reinforced plastics, including glass fibers, carbon fibers, and aramid fibers, is gaining prominence. These reinforcements impart increased strength and stiffness to the molded components, making them suitable for applications in automotive, aerospace, and industrial sectors.

Bio-Based Plastics: The emphasis on sustainability is driving the adoption of bio-based plastics derived from renewable sources. Experts on plastic injection molding in Kansas are exploring materials such as PLA (polylactic acid) and biodegradable polymers to align with eco-friendly practices and cater to environmentally conscious industries.

Industry 4.0 Integration:

The wave of Industry 4.0, characterized by the integration of smart technologies and data-driven processes, is making significant inroads into the world of Kansas plastic injection molding. Smart manufacturing practices are enhancing efficiency, precision, and overall operational excellence.

IoT-Enabled Monitoring: Internet of Things (IoT) devices are being integrated into injection molding machines to enable real-time monitoring of key parameters. Data on temperature, pressure, cycle times, and machine status are collected and analyzed, facilitating predictive maintenance and optimizing production processes.

Digital Twin Technology: Experts on plastic injection molding in Kansas are adopting digital twin technology, creating virtual replicas of the injection molding process. This allows for simulation, analysis, and optimization of manufacturing processes before actual production begins, reducing the likelihood of defects and improving overall efficiency.

Precision and Micro-Molding:

As industries demand smaller and more intricate components, the realm of micro-molding is expanding in Kansas. Micro-injection molding, characterized by the production of tiny and precise plastic parts, is finding applications in medical devices, electronics, and telecommunications.

Miniaturization: Advancements in tooling and machine technology are enabling the production of miniature components with high precision. Kansas plastic injection molding professionals are catering to the growing demand for miniaturized parts in industries where space constraints and lightweight designs are paramount.

Tight Tolerance Molding: The pursuit of perfection in component dimensions has led to the development of injection molding processes with tight tolerances. Kansas manufacturers are leveraging advanced molding techniques to achieve precise tolerances in the sub-micron range, ensuring the production of components that meet the most demanding specifications.

Multi-Material Plastic Injection Molding in Kansas:

To meet the evolving requirements of diverse industries, Kansas injection molders are increasingly adopting multi-material molding techniques. This involves the simultaneous or sequential injection of different materials into the same mold, creating components with varying characteristics in a single operation.

Overmolding: The term overmolding means a form of multi-material molding. The process involves the injection of one material over another to create a composite structure. This is utilized for applications where a soft, ergonomic grip is combined with a rigid structural component.

Soft-Touch Components: The integration of soft-touch materials, such as TPE (thermoplastic elastomer), with rigid plastics is gaining traction. This is particularly relevant in the production of consumer goods, electronic devices, and automotive interiors where tactile feel and aesthetics are crucial.

Rapid Prototyping and 3D Printing Integration:

The synergy between plastic injection molding and rapid prototyping technologies, including 3D printing, is fostering innovation and accelerating product development cycles in Kansas.

Prototyping with Additive Manufacturing: Experts on Kansas plastic injection molding are leveraging the capabilities of 3D printing to produce rapid prototypes of molds and components. This facilitates quick design validation, iteration, and testing before committing to full-scale production.

Bridge Tooling: The integration of 3D-printed molds for low-volume production, known as bridge tooling, enables manufacturers to bridge the gap between prototyping and full-scale manufacturing. This approach allows for cost-effective production of limited quantities while final tooling is being developed.

Plastic Injection Molding in Kansas and Sustainable Practices:

The growing emphasis on sustainability and environmental responsibility is influencing plastic injection molding practices in Kansas. Manufacturers are adopting eco-friendly materials, optimizing energy consumption, and implementing recycling initiatives.

Recycled Plastics: Injection molders incorporate recycled plastics into their processes, contributing to circular economy practices. This not only reduces the environmental impact but also addresses the demand for sustainable solutions from conscious consumers and industries.

Energy-Efficient Processes: Optimizing energy consumption in injection molding machines is a priority in Kansas. Efforts to reduce energy use during heating, cooling, and overall machine operation are contributing to both cost savings and a reduced carbon footprint.

LeVic Plastics: Embracing Innovation in Kansas Plastic Injection Molding

As a leading player for plastic injection molding in Kansas, LeVic Plastics is at the forefront of embracing innovation and pushing the boundaries of what’s possible in plastic component manufacturing. Our commitment to delivering high-quality, precision-engineered components aligns with the evolving needs of industries across the state and beyond.

Key Pillars of Innovation at LeVic Plastics:

Investment in Technology: LeVic Plastics continually invests in state-of-the-art injection molding machines, tooling, and automation to stay at the cutting edge of technology.

Material Expertise: Our team’s deep knowledge of plastic materials allows us to recommend and utilize the most suitable materials for each project, considering both performance requirements and sustainability goals.

Customization and Prototyping: We understand the importance of customization and rapid prototyping in today’s fast-paced industries. LeVic Plastics leverages rapid prototyping technologies and flexible manufacturing processes to deliver tailored solutions to our clients.

Quality Assurance: Stringent quality control measures are ingrained in our processes, ensuring that each molded component meets or exceeds industry standards. Our commitment to precision is unwavering.

Collaboration and Problem-Solving: At LeVic Plastics, we believe in collaborative partnerships. We work closely with our clients to understand their unique challenges, providing innovative solutions and problem-solving expertise.

Looking Ahead: The Future of Plastic Injection Molding Services in Kansas

As we look to the future, the landscape of plastic injection molding in Kansas holds exciting possibilities. The convergence of advanced materials, smart manufacturing practices, and sustainability initiatives is poised to reshape the industry. LeVic Plastics, with its forward-looking approach and dedication to excellence, is well-positioned to contribute to and lead this transformative journey.

Innovation is not merely a buzzword at LeVic Plastics; it’s embedded in our DNA. As Kansas continues to thrive as a hub of manufacturing excellence, the role of injection molding in driving progress, meeting evolving needs, and contributing to sustainable practices will only become more pronounced.

In conclusion, the world of plastic injection molding in Kansas is not just adapting to change; it’s driving change. From the adoption of advanced materials to the integration of Industry 4.0 technologies, Kansas injection molders are pioneering new frontiers.

LeVic Plastics, standing tall in this dynamic landscape, invites you to explore the possibilities that innovation in plastic injection molding can unlock for your projects. As we journey into the future, the Sunflower State’s contribution to the world of plastics will undoubtedly continue to blossom.

Are you searching for top-notch injection molding services in Kansas? Look no further than LeVic Plastics. Our team of injection molding professionals provide the best quality and fastest production run possible. We offer EDM machining in Kansas, CNC machining, and other tooling services to ensure your project is completed properly and on time. At LeVic Plastics, we have the staff, expertise, and equipment to assist with your next project.

From large-scale orders to limited production runs in Kansas, our LeVic team will complete your order with the utmost service, quality, and efficiency. We are located just outside the Kansas City area in Grandview, MO, and would love the opportunity to assist with your next project.

We specialize in numerous production methods, including injection molding, CNC machining in Kansas, and other tooling services in Kansas. We’ll work closely with you to find the best option for your next production run.

To get started, call (800) 231-1232 or click here to get a free quote.

We look forward to hearing from you soon!