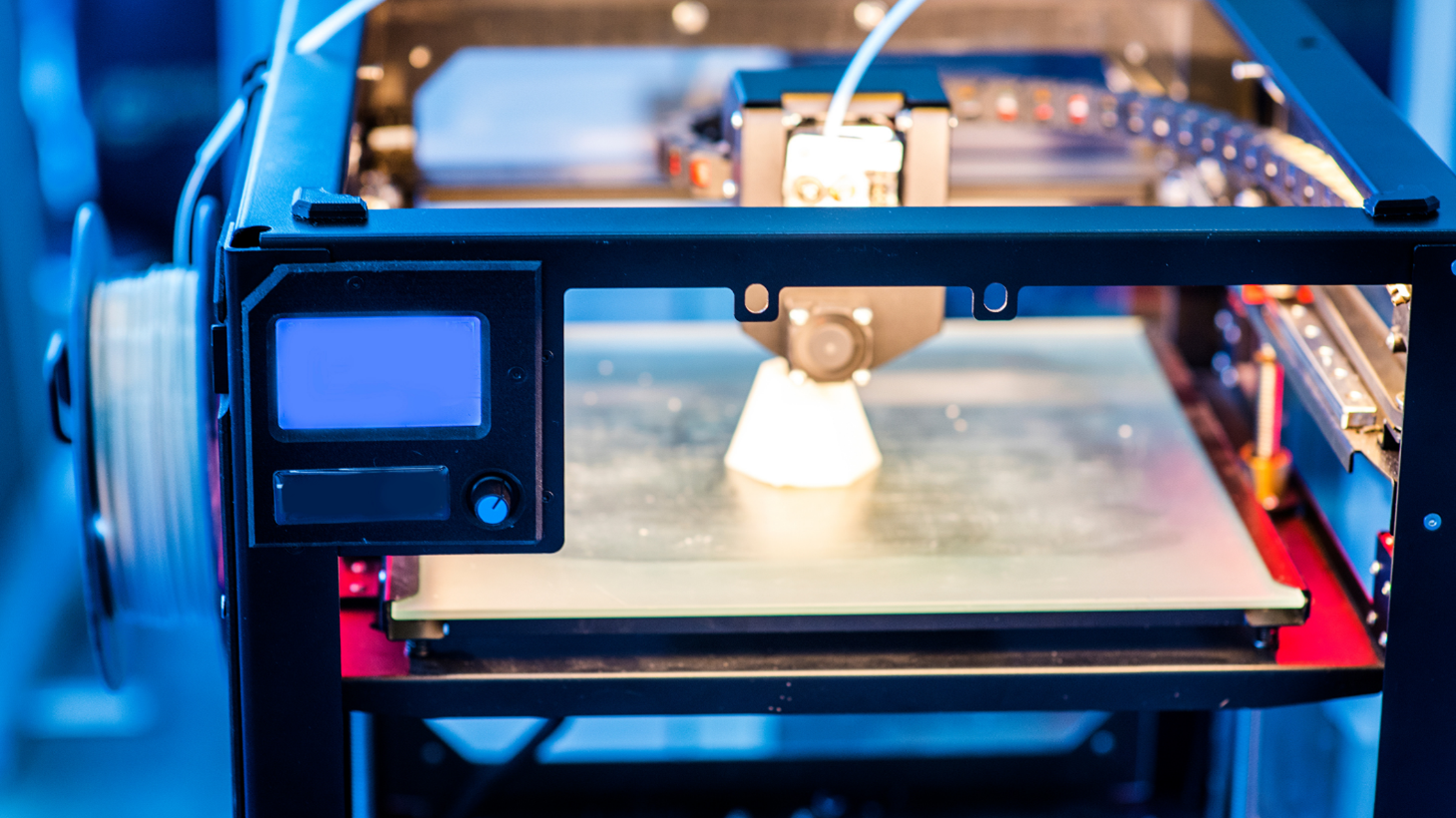

When companies need a large order fulfilled, whether it’s parts or massive quantities of a product, they often rely on plastic mold manufacturing in Missouri. This highly efficient production process can be repeated over and over with very few hiccups. It is efficient and can produce large volumes of plastic parts or products.

If you are searching for a reliable company for plastic mold manufacturing in Kansas City, LeVic Plastics is here to help. However, before we get started with your project, there are three very important factors to consider. In this blog, we’ll review each of these items to ensure you are fully prepared for your upcoming production run with a plastic injection molding company in Kansas City.

These three critical factors are:

- Designing the Item

- Producing the Item

- Overall Costs

Designing the Item

As a leader in plastic mold manufacturing in Missouri, our team at LeVic Plastics knows it is important to carry out your production run with quality and efficiency. A good design can go a long way towards ensuring a successful project. Take time to really consider the most important traits of your design. Do you want to keep production costs as low as possible? Do you want to keep the design simple? Do you know the fine details about what you’ll need to finish the project? Consider these questions and any other concerns before your get too far in the design process.

Producing the Item

An important part of any production run is knowing how many parts or units need to be produced. Most companies that specialize in plastic mold manufacturing in Kansas City will first determine if the project is “high volume” or “low volume.” High volume production runs can involve hundreds of thousands of parts, while low volume runs are commonly below 10,000 units.

Next, consider any time constraints that might get in the way of completing the project. Set realistic deadlines to ensure that the project can be finished on time, even if there are a few hiccups or delays during production.

Overall Costs

It is important to know what your budget is from the very beginning. One important thing to consider is that plastic mold manufacturing in Missouri typically costs extra upfront. This is due to prototype designing, creating the molds, and product testing.

Then, make sure your production run is cost-effective. Get accurate quotes on the total costs if you need 10,000 units, 20,000 units, or whatever number you might need. The size of your order could significantly change the price per unit. Make sure you consider this before deciding on how many units to purchase for your project.

Contact LeVic Plastics Today!

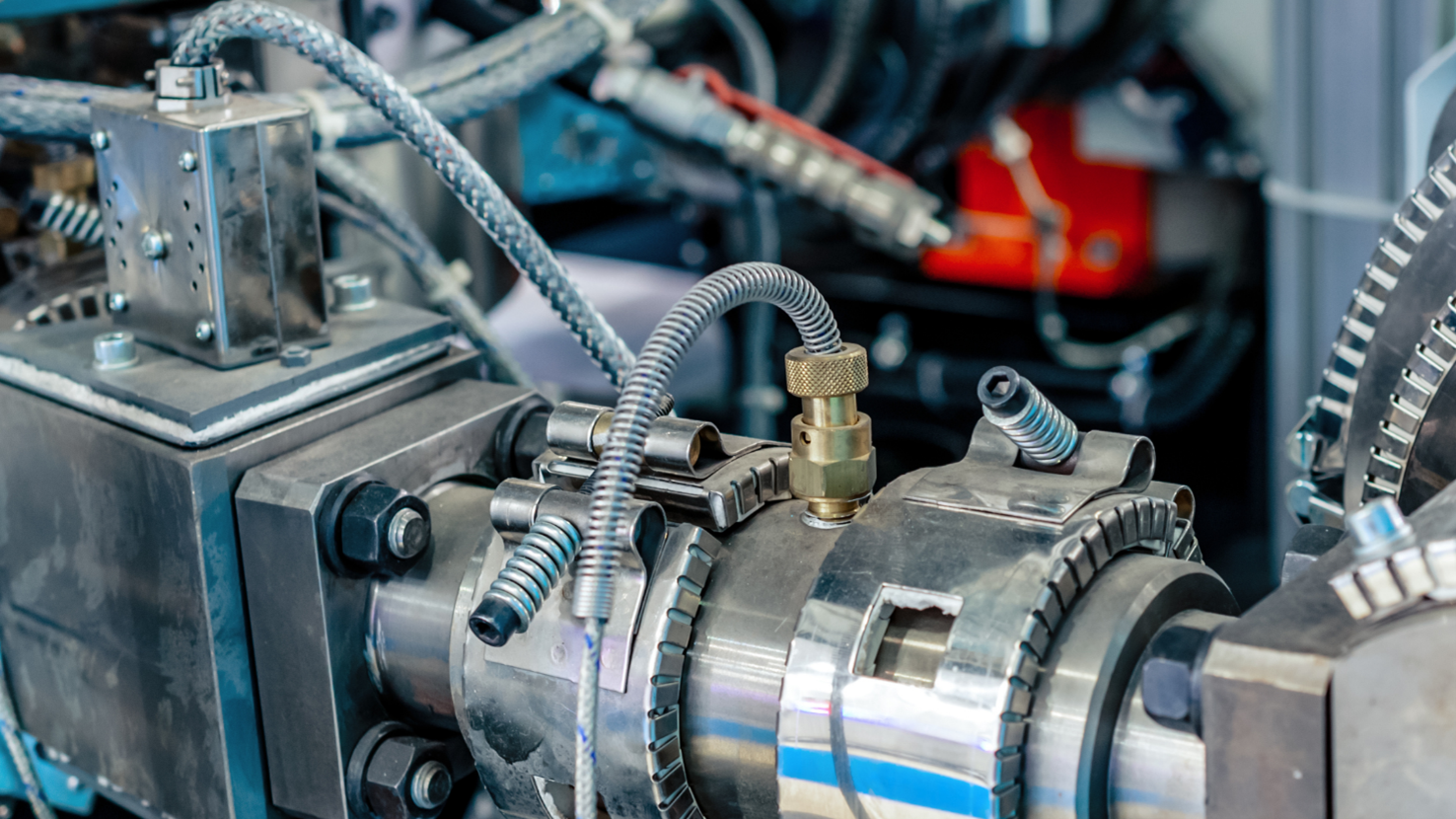

Do you have a project involving plastic injection molding, EDM machining, or CNC machining in Missouri? If so, LeVic Plastics is ready to help. Since 1971, we have been assisting clients by designing and creating the best products and parts through our proven tooling services in Missouri. We thrive on consistency, hard work, and customer service at LeVic Plastics, and we’ll make sure your next production run is completed as efficiently as possible.

To get started, give us a call today at (800) 231-1232 or contact us online to get a free quote. We look forward to working with you!