For the most complex designs, CNC machining in Missouri is the preferred manufacturing method for many experts to ensure the most accurate results. CNC (Computer Numerical Control) machining is widely regarded as the most precise method for creating the highest quality models in large quantities. Here are some of the reasons why CNC machining continues to be one of the most popular manufacturing methods over traditional tooling services in Missouri.

Fewer Workers Required

For many manual lathing methods, a skilled technician is required at each individual machine. One of the most significant benefits of CNC machining is that one trained employee has the capacity to operate multiple machines at once. CNC machines offer accurate cuts for the most precise and complex designs. These cuts are configured into the machines and require minimal human contact, which means significantly less risk of any production errors.

More Axes Means More Cuts

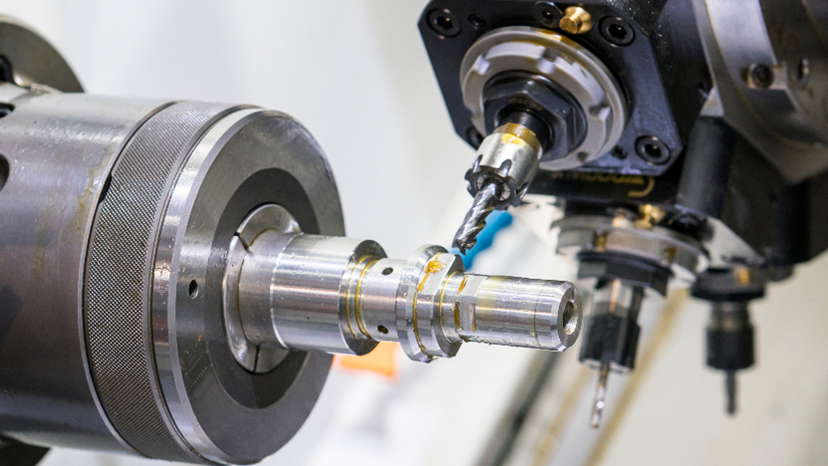

Some of the more basic machines, that don’t utilize CNC technology, only make cuts along the x and y axes of a specific design. However, CNC machining in Missouri automates any job that requires several different cuts.

A spindle or router will turn the cutting implement, which looks similar to a drill bit, and makes the proper cuts to the material. CNC’s programming during this process allows for high-speed movements to provide rapid production while still emphasizing all the fine details needed to make high-quality products.

Fabricating Metal and Plastic

Today, manufacturers require more and more shapes that simply cannot be done accurately using traditional tooling services in Missouri. CNC machining is quickly becoming the most popular manufacturing method for many industries that use more complex designs for their products.

Round the Clock Production

For some manufacturing processes, they must shut down after a certain amount of hours of operation. Or they are turned off when workers go home for the day. CNC machining in Missouri can keep going day and night, and only needs to be stopped if repair or routine maintenance is required.

Designs Can Easily Be Saved and Re-Used

CNC machines can retain all the design information used to make an original prototype and then use that information for the next run. This saves manufacturers the trouble of re-creating a design each time there is a new order.

Now that you’ve read about the advantages of CNC machining, let us know if you think CNC would be best for your next project. If not, we offer other production methods such as injection molding assembly or EDM machining in Missouri.

Whether it’s a large production run or limited production runs in Missouri, we will help you with each step at LeVic Plastics. Give our team a call today at (800) 231-1232 or go online for a free quote.