A common way of producing plastic parts today is through the process of custom plastic injection molding in Missouri. It is a fast process that is most beneficial for projects that require the production of the same part, in large quantities, and in a very short amount of time.

Although the process of making custom plastic injection molds in Missouri can be complex, this article will try to simplify the process for you. We will quickly cover some of the most important steps involved with plastic injection molding.

What types of plastic are used for custom plastic injection molding in Missouri?

Before the injection process can begin, manufacturers and designers need to ensure that they are using the correct type of plastic for a specific project. Some of the most commonly used plastics today are thermoplastic, elastomer, and thermoset. These high-performing plastics have actually replaced metals that used to be a staple in the plastic manufacturing industry.

Melting the Plastic

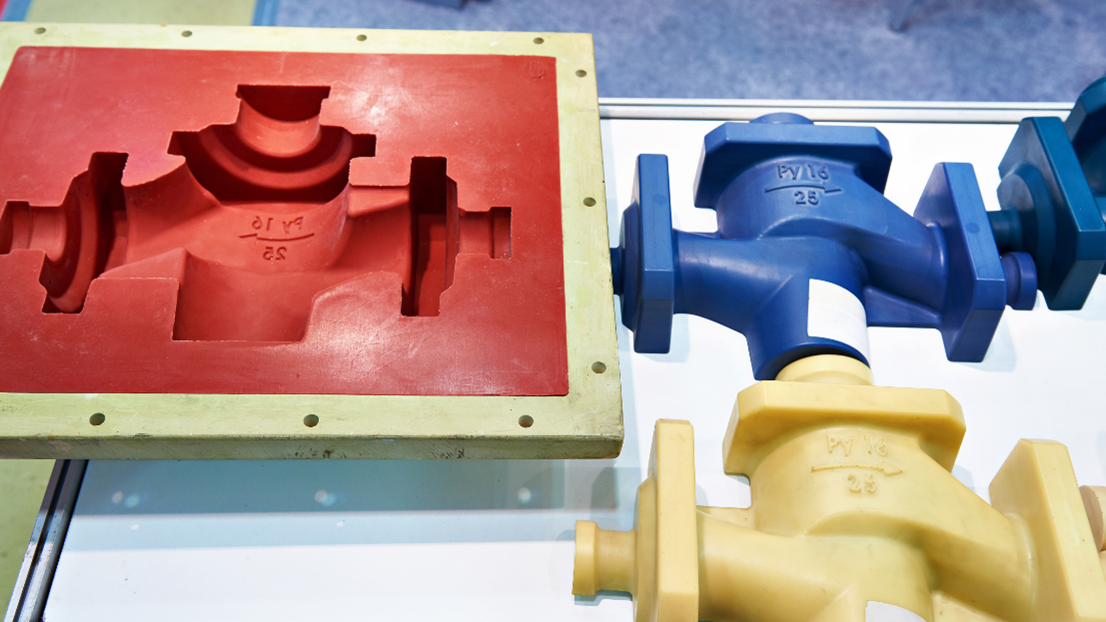

Plastic is initially put under intense heat and is melted inside a machine that is specifically designed for custom plastic injection molding. After the plastic has reached the desired temperature and consistency, it is injected into either aluminum or steel molds in Missouri and left to cool.

Once the plastic has cooled, the two halves of the mold are opened which allows the newly shaped plastic to be released. The plastic has now been formed into the exact shape of either the steel or aluminum molds in Missouri. These molds that helped shape the plastic were initially constructed by either an engineer or a designer before the plastic was injected.

Speeding Up the Process

Although the process of using custom plastic injection molds in Missouri should not be rushed, manufacturers are always looking for ways to speed up production and save on costs. Production costs can be lowered if any of the following items are decreased.

- Injection Time

- Cooling Time

- Changeover Time

The more frequently molds are changed, the more it allows inventory to be reduced and can result in faster responses to the market’s requirements. If molds are changed quickly, it could result in a decrease in overall manufacturing costs.

Again, this is just a brief outline of the detailed process known as custom plastic injection molding in Missouri. If you have any questions for our team at LeVic Plastics regarding injection molding or any of our other processes, give our team a call at (800) 231-1232 or contact us online for a free quote. We look forward to assisting you with your next project run.