Engineers across Missouri know that there are multiple ways to manufacture parts and products. For the most basic projects aluminum molds in Missouri or steel molds in Missouri will get the job done, but what about more complex designs?

EDM machining in Missouri may be the best option for manufacturing objects with very sophisticated design requirements. EDM (Electrical Discharge Machining) is most widely used to form complex shapes into very hard metals. Materials that are often difficult to machine using non-EDM methods are hardened steel, tungsten carbide, and machining dies.

EDM In-Depth

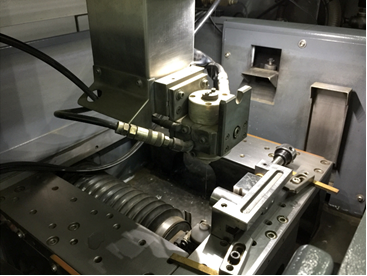

More specifically, EDM machining in Missouri uses timed electrical pulse to help remove material from the workpiece. During this process, a power supply controls both the intensity and timing of the electric charges, as well as the movement of the electrode. The entire process involves no touching of the workpiece which allows for tighter tolerances and cleaner finishes on each piece.

Different Types of EDM

There are multiple variations of EDM that are used for different functions. Three of the most common types of EDM are:

- Ram EDM

- Drill EDM

- Wire EDM

Ram EDM

Also known as plunge or standard EDM, Ram EDM is the oldest form of EDM machining. Ram EDM consists of an electrode made of graphite which will make a cavity on the workpiece. Another use of RAM EDM is to create holes that go completely through workpieces.

Drill EDM

It is no coincidence how Drill EDM got its name, as the main purpose of Drill EDM is to perform tasks similar to a drill press. A drill press would be ineffective in trying to drill through hard metals or steel, so that is where Drill EDM comes in. Also, the accuracy of Drill EDM is far superior to using a drill press, no matter what materials you are using.

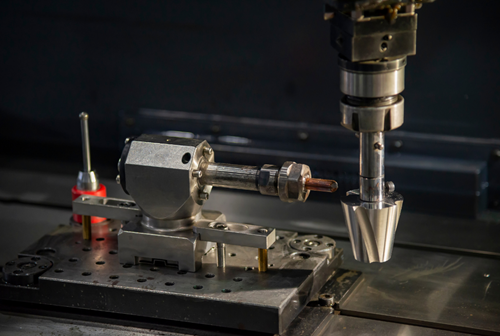

Wire EDM

When a traveling wire electrode goes through the workpiece and is controlled by a computer to make modifications, this is known as Wire EDM. The wire is typically .010” in diameter or smaller so that it can customize the workpiece down to the most exact specifications.

Now that you know more about the benefits of using EDM machining in Missouri, contact LeVic Plastics if you think EDM is the best option for your next project. Our team of experienced designers and engineers can help you get your order complete in a timely manner. We can handle the biggest orders or smaller requests with limited production runs in Missouri.

No matter your project, LeVic Plastics will provide the right tooling services in Missouri for you. Contact us online or call (800) 231-1232 to get started today!