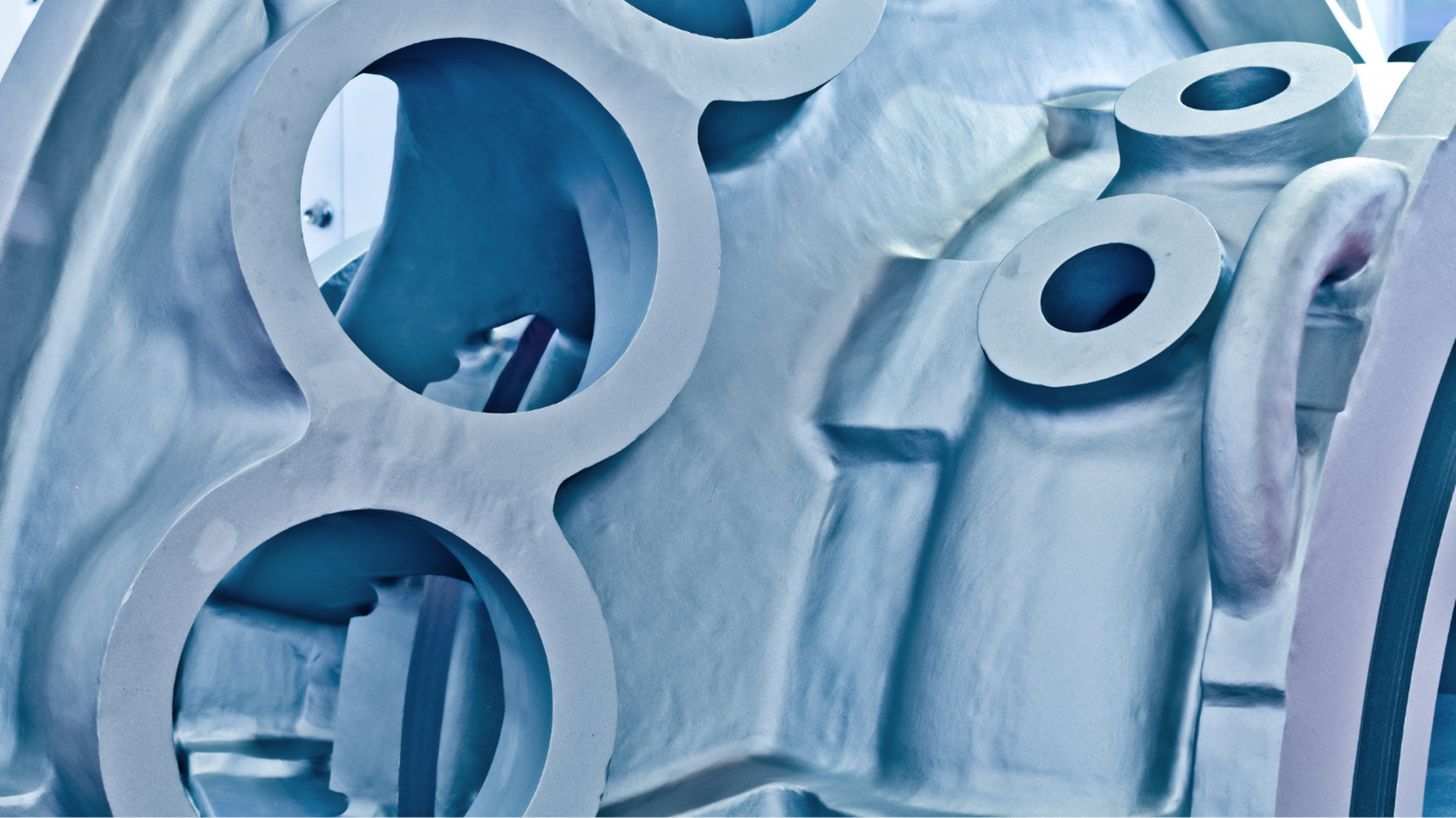

One of the great debates when it comes to manufacturing plastics parts is, “Do I go with steel molds or aluminum molds in Missouri?” There are advantages to using either option as they both have their strengths and weaknesses when they are compared to each other. However, in this article, we are going to focus primarily on the benefits of aluminum molds to help you determine if this is the best option for your next project.

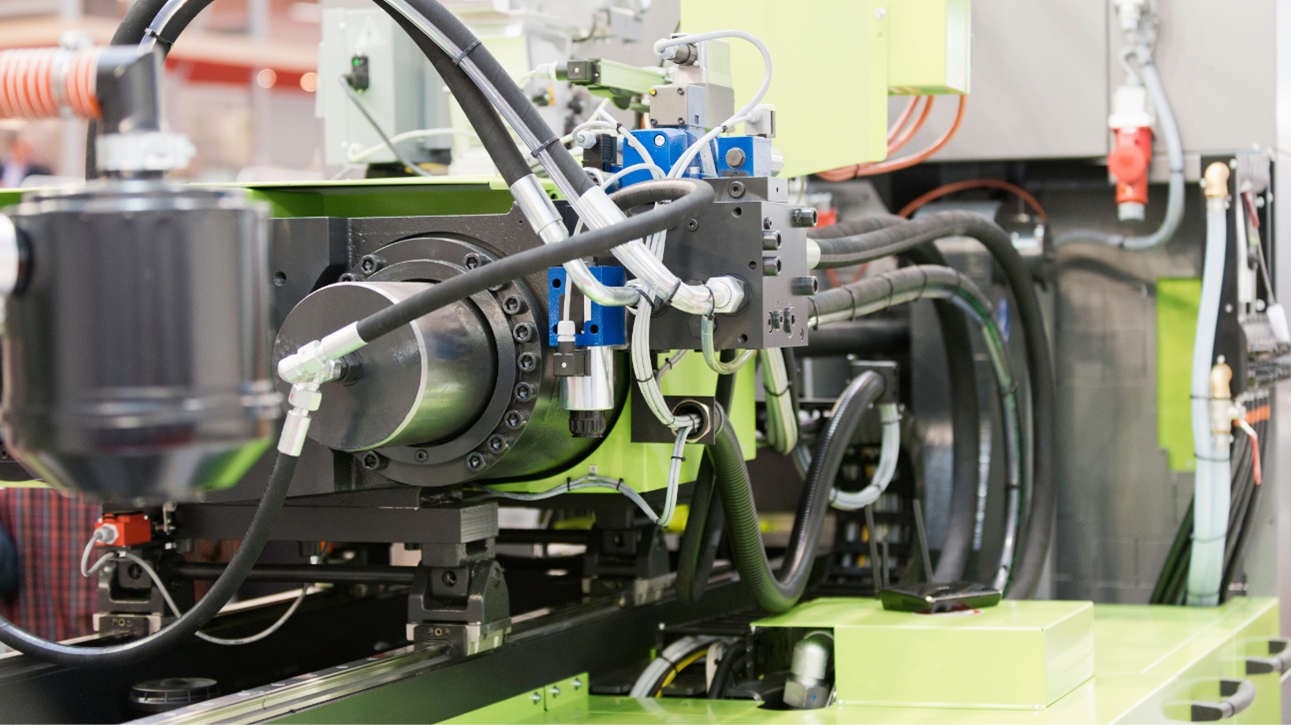

Faster Cycle Times

If you have an order for plastic parts that need to be completed as soon as possible, aluminum molds are a great option. For custom plastic injection molds in Missouri that use aluminum, you can expect the parts to be cycled through anywhere from 20% to 30% faster than steel molds. In fact, many equipment manufacturers in the automobile industry are suggesting that their suppliers switch completely to aluminum molds when possible. It only makes sense to use the mold material that is more efficient and can produce more parts in a shorter time period.

“…many equipment manufacturers in the automobile industry are suggesting that their suppliers switch completely to aluminum molds when possible.”

Aluminum Molds Cost Less than Steel Molds in Missouri

On average, creating an aluminum mold is about ¼ to ½ the cost of creating a steel mold. This makes aluminum molds in Missouri a far more cost-effective option. Also, if your mold requires modifications down the road, it costs far less to change than a steel mold. It is estimated that an aluminum mold modification costs about 10% as much as it would to change a steel tool. Another benefit of aluminum molds is that they can be adjusted much more quickly than steel because they are not as hard, they’re lighter, and overall, much easier to work with.

Aluminum Requires Less Time to Make

Designing and creating molds takes much more time than what most people think. A steel mold could take anywhere from 35 to 60 business days to create, while an aluminum mold is still time-consuming but can be created much more quickly than steel. Aluminum molds in Missouri usually take around 15 to 25 business days to create.

How Long Can Aluminum Molds Last for a Project Involving Custom Plastic Injection Molding in Missouri?

These numbers can vary depending on what type of plastic is used for the project. However, on average, a project that uses steel molds can have a lifespan ranging from 50,000 to 100,000 parts. Meanwhile, a large project involving custom plastic injection molds in Missouri made of aluminum; those molds could last anywhere from 10,000 to 25,000 parts. So you get plenty of longevity using aluminum molds for your parts, just not as much compared to steel. Be sure to consider how many parts you are going to need to be produced before you make your final decision on metal or steel for your molds.

As one of the leading companies for plastic injection molding services in Missouri, LeVic Plastics can answer all your questions and concerns regarding aluminum and steel molds. Give our team a call today at (800) 231-1232, or you can get a free quote for your upcoming project by clicking here.

Thank you for your interest in LeVic Plastics; we look forward to working with you soon.