At LeVic Plastics, we are one of the leaders in plastic injection molding in Kansas City, and we take great pride in our work. Our team knows that plastic injection molding is a highly successful production method for numerous reasons. This article will outline some of biggest the advantages of Kansas City plastic injection molding over other production methods. They are:

- Strength and Durability

- The Automated Process

- Can Use Multiple Plastics at the Same Time

- Detailed Designs

- Efficient Process

Strength and Durability

Adding fillers to the molds is a common practice used by a typical Kansas City plastic injection molding company. This reduces the density of the plastic but adds extra strength to the parts once they have been molded. Fillers are typically not offered by other manufacturing processes, making injection molding one of the best options for creating parts with high strength and durability.

The Automated Process

One way to keep costs down during production is by finding automated processes that require less energy and human labor. Plastic injection molding in Kansas City is performed mostly by machines and robotics, which can be controlled by one sole operator. With only one worker needed, this reduces manufacturing costs and reduces overheads rather significantly. This helps keep prices lower for clients and encourages repeat business.

Multiple Plastics Can Be Used at the Same Time

Many clients prefer to use multiple types of plastic to complete one project or production run. This isn’t an option with many commonly used manufacturing methods. However, this is possible when you hire a Kansas City plastic injection molding company, like LeVic Plastics. Through a process called co-injection molding, parts and products can be made as needed using multiple plastics.

Detailed Designs

Injection molds are often subjected to high pressure, which means the plastic will be pressed very hard against the mold. When there is high pressure, it allows for the engineers and design team to add some significant detailing to the part. Highly-detailed designs can often be quite expensive and too complicated when using other methods. The high pressure allows for more options and it’s why many people choose a Kansas City plastic injection molding company, like LeVic Plastics, for their production runs.

Efficient Process

After the molds have been designed, created, and pre-programmed, the process of making the parts goes rather quickly. Swift manufacturing times make plastic injection molding companies in Kansas City a very economical choice for production runs of any size. This efficient process also results in more parts per mold, meaning that far less molds need to be made in order to complete the project.

Are You Ready to Hire One of the Top Kansas City Plastic Injection Molding Companies?

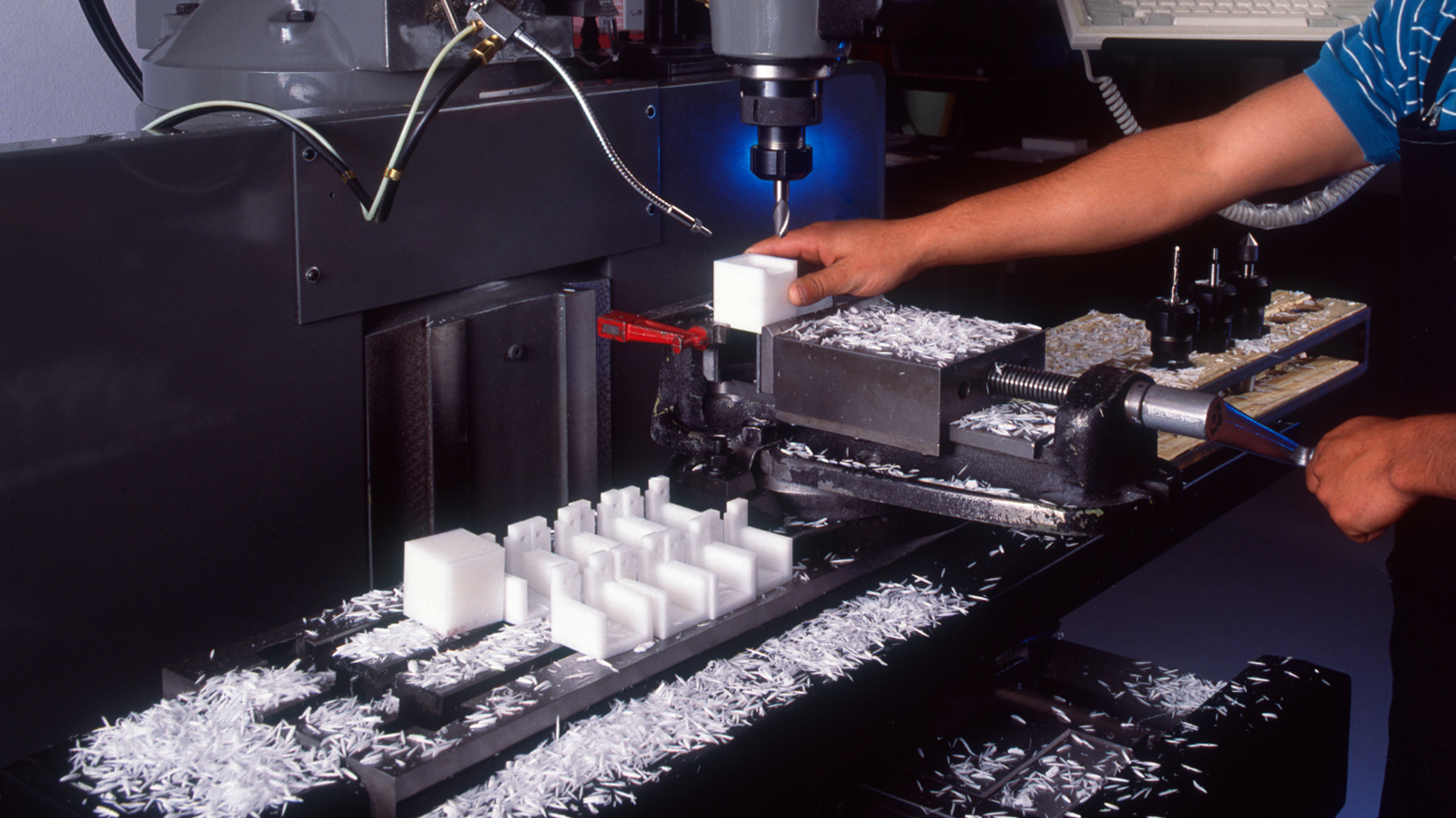

At LeVic Plastics, we offer premium solutions for large part orders or limited production runs. With our years of expertise in CNC machining, EDM machining, and injection molding, we’ll complete your project with utmost service and quality every time.

Call us today at (800) 231-1232 to discuss your next project. You can also contact us online to receive a free quote.