At LeVic Plastics, we design and create custom parts and products using numerous production methods. We specialize in CNC machining, plastic mold manufacturing, and plastic injection molding in Missouri. On top of all that, we are also many customers’ trusted resource for EDM machining in Missouri.

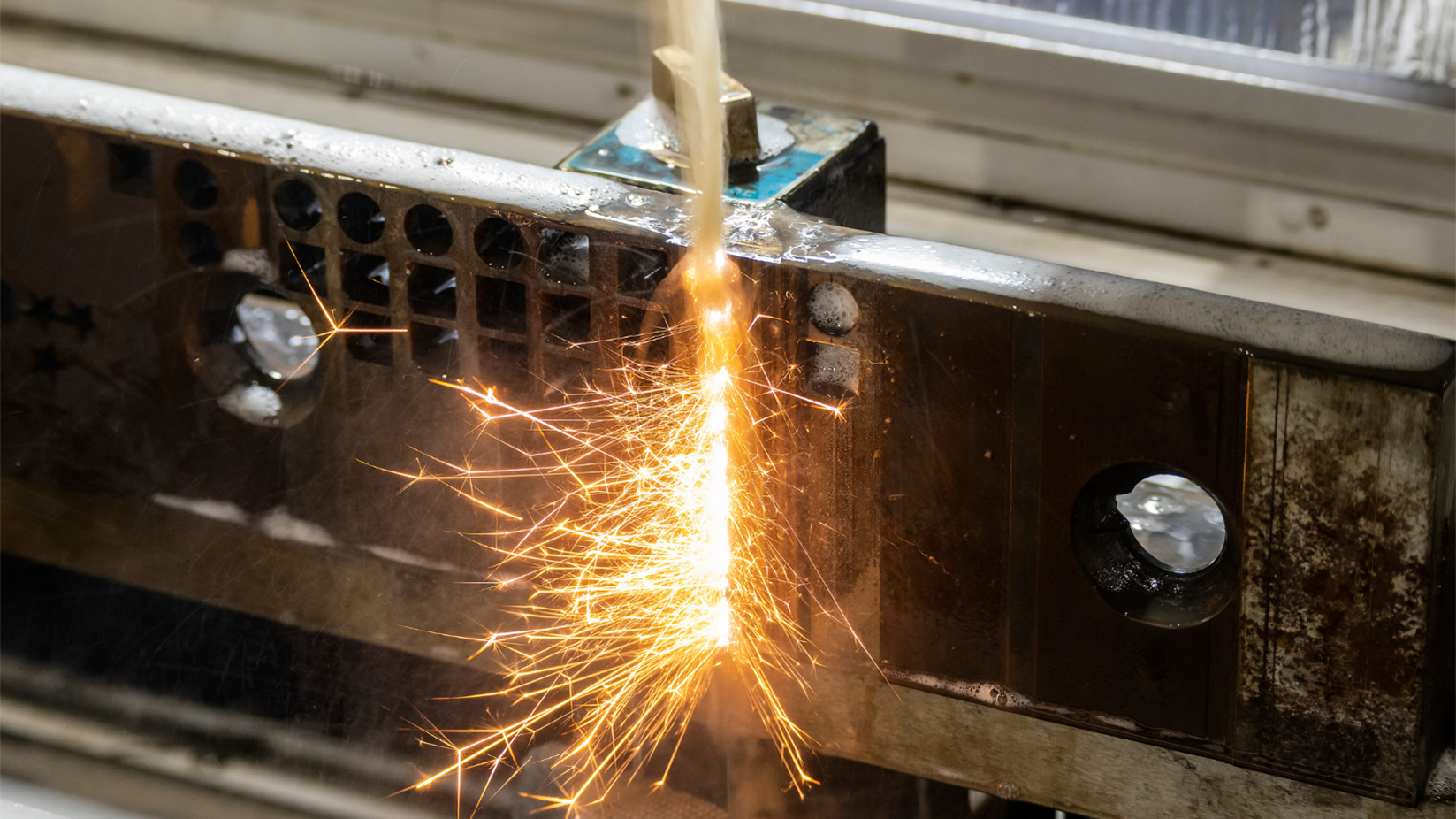

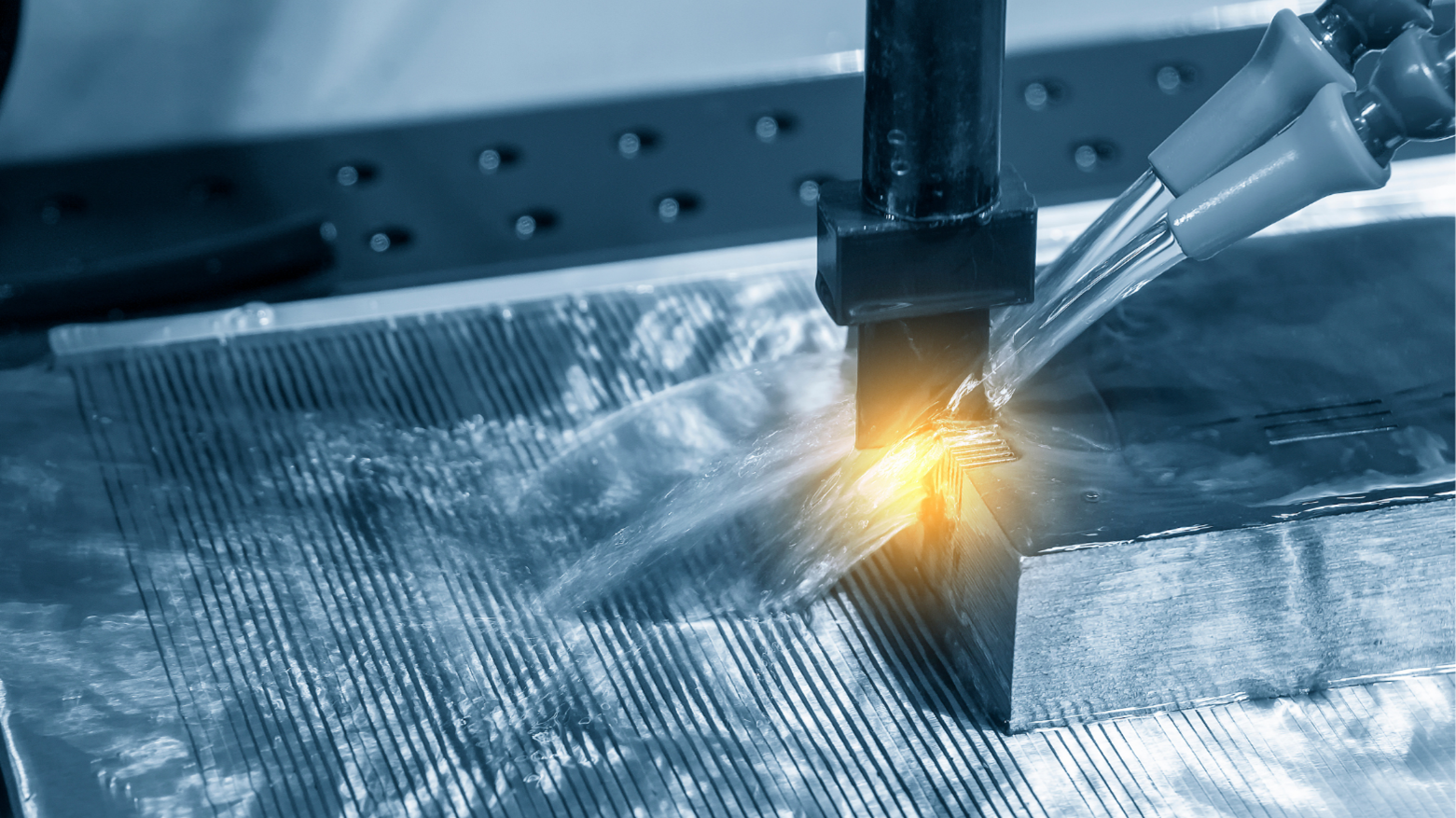

EDM machining is known by several other terms, including spark eroding, spark machining, wire burning, and die sinking. Many projects are completed using EDM machining in Kansas City because parts and products can be customized to the client’s needs using electrical discharges.

The machinery used during the EDM process is crucial to ensuring the highest quality and most accurate parts/products. Today we’re going to discuss some very important tasks that EDM operators should do to improve the performance of their machines. By following these steps, the machines are less likely to break down and are more likely to remain consistent during production.

Check and Replace Air Filters as Needed

Just like with our HVAC units at home or in our vehicles, air filters play an important role when it comes to EDM machining in Missouri. An EDM machine’s air filter protects one of the machine’s most critical components – the EDM center. This is where many boards, circuits, and electrical elements are located. To operate smoothly, these all require cool and clean airflow.

The machine’s small air filter is usually located in the generator’s door and is used to gather dust and small particles. The machine operator should make sure filters are replaced as needed to keep all sensitive areas clear of dust and debris.

Check and Replace the Power Feed Cables

One thing that can slow down EDM machining in Kansas City is when the power cables begin to age. The cables play an essential role in getting energy to the machine. When they are not functioning at 100% effectiveness, it can result in production slowdowns and inconsistent part/product quality.

Unlike a power board failure which results in a complete shutdown, damaged or ineffective power cables cause the machine to gradually slow down and reduce production. Missouri EDM machining operators are often wowed by how much more efficient the machine is after the cables are replaced.

Inspect All Cooling Fans

When an EDM machine overheats, it can completely stop production. A machine can overheat when it is asked to do too much in a short amount of time, or if it does not have an effective cooling system. Cooling fans play a key role in keeping EDM machines running at maximum efficiency. Their job is to provide air circulation to the generator cabinet, which then keeps boards and other components from getting too hot.

Cooling fans should be checked daily when starting up the machines. When the fans are working properly, they will extend the overall life of the power supply and the EDM system.

LeVic Plastics, Your Source for the Most Dependable Tooling Services in Missouri

If you are looking for a dependable, honest, Kansas City area company to assist with your next production run, look no further than LeVic Plastics. We have you covered for everything from plastic injection molding, to CNC machining, to Kansas City EDM machining projects.

To request a free estimate, fill out our contact form here. You can also call us at (800) 231-1232, and we will be glad to assist you.