Steel Milling in Kansas City: Why Precision and Durability Go Hand in Hand–When your parts need to hold up under pressure—literally—there’s no substitute for steel. At LeVic Plastics, we’ve carved out a strong reputation as a go-to source for steel milling in Kansas City. And while plenty of shops can work with steel, few have the systems and team in place to do it as precisely and consistently as we do.

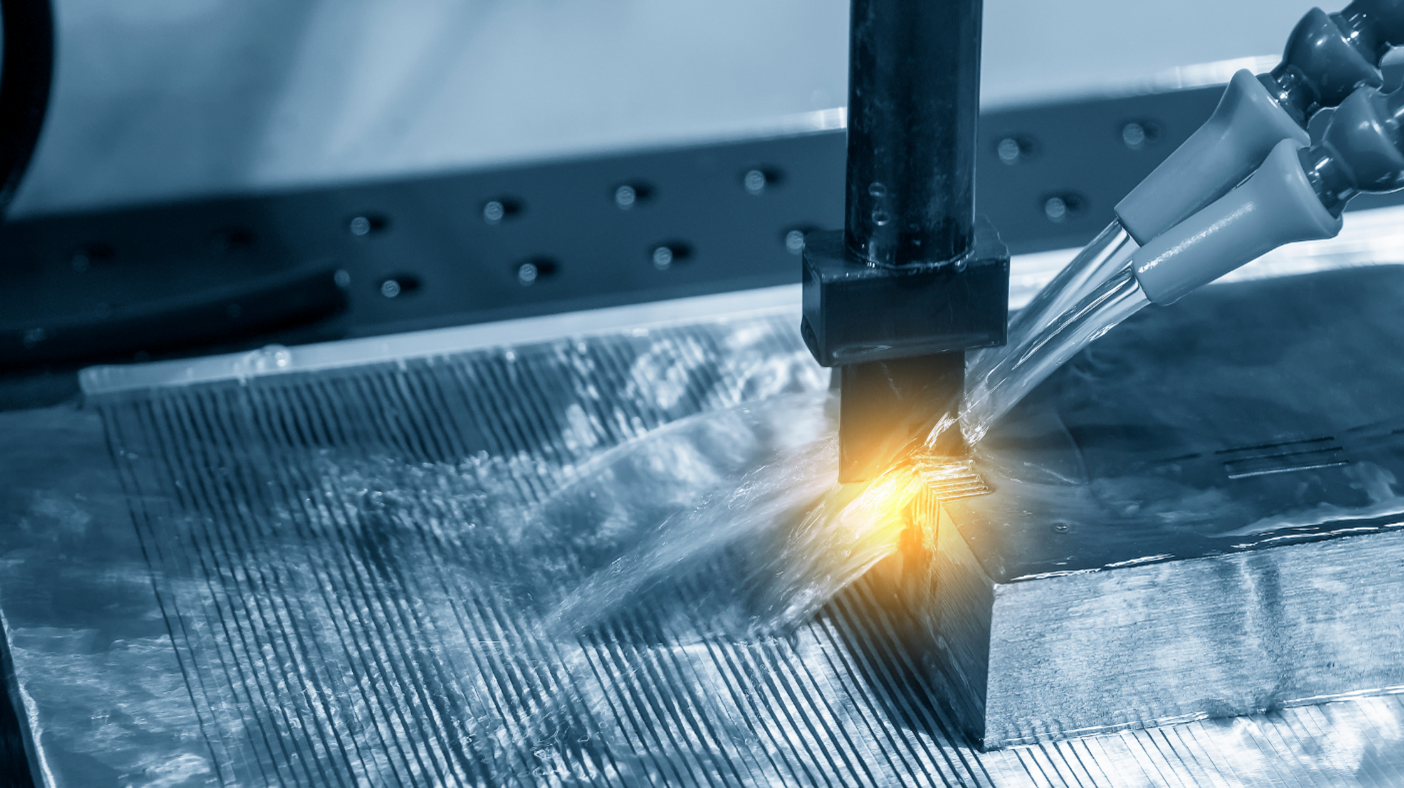

Steel is strong, but it’s also tricky. If your machining setup isn’t dialed in just right, you’ll burn through tools, lose accuracy, and waste both time and money. That’s why we’ve invested in high-performance CNC systems, smart tooling strategies, and a crew of machinists who treat every job like it’s for something critical—because it usually is.

It All Starts with the Right Machines

We don’t just “make it work”—we’re built for it. Our Kansas City facility runs a range of mills designed to cut cleanly through even the hardest grades of steel. Whether we’re creating large components or small, complex geometries, we rely on our CNC machining in Kansas City capabilities to keep things smooth, fast, and precise.

Tight tolerances? No problem. Complicated features? Bring them on. We run everything through toolpath simulation first to avoid costly mistakes, and our quality control team checks dimensions during and after production to make sure nothing slips through the cracks.

When you ask us for steel milling in Kansas City, you’re getting parts that are built to hold their shape, perform under pressure, and fit exactly how you need them to.

3-Axis Milling That Works Fast—and Smart

Let’s talk efficiency. Our 3 axis CNC machining in Kansas City setups allow us to handle most milling jobs with speed and accuracy. For clients, that means lower costs, shorter lead times, and fewer surprises.

And we don’t just program and press start. We monitor each run to ensure the feed rates and tool life are balanced, making adjustments on the fly when needed. That’s the kind of attention you only get when you’re working with a team that actually cares about the outcome.

Tough Materials Need Smart Machining

We love working with steel, but we respect it, too. It takes the right RPM, the right coolant flow, and the right tool strategy to get clean edges and a flawless finish. That’s why so many clients trust us for steel turning in Kansas City and milling—because we know how to do it right, the first time.

And whether we’re making parts for construction equipment, aerospace tools, or medical devices, our crew approaches every job with the same level of care. No shortcuts. No guesswork.

Where Lathe Work and Milling Meet

Many of our projects start with turning and finish with milling—or vice versa. These two processes are essential for creating complex, high-quality components with precise specifications. Since we handle both turning and milling in-house, it’s easy to streamline your entire project right here in our shop. This seamless workflow not only saves time but also ensures consistency and accuracy throughout the manufacturing process. It’s especially beneficial for clients who require a combination of precise diameter cuts and detailed features, such as milled slots, holes, or grooves. By managing everything under one roof, we can deliver efficient, reliable results for even the most intricate designs.

We’re often asked to finish components that start on our lathes, thanks to our reputation for quality lathe work in Kansas City. It’s this full-package approach that helps reduce handoffs and speed up final delivery.

Your Kansas City CNC Team

Sure, you could ship your job to another state. But when you choose Kansas City CNC machining, you get the kind of speed and support that only comes from working with a local team. We’re easy to reach, fast to respond, and right here when you need to tweak a spec or accelerate a job.

We also know the Kansas City market inside and out—whether it’s manufacturing, aerospace, medical, or other industries—we have a deep understanding of the unique timelines, challenges, and expectations our clients face. Our team leverages years of experience in these sectors to anticipate needs and deliver tailored solutions. We’ve designed our systems to be flexible and efficient, ensuring we can help meet your goals, deadlines, and quality standards time and time again.

You’ve Got an Idea. We Know How to Build It.

Whether you’ve got a sketch on a napkin or a full-blown product line, we’ll help you get your parts made—without the runaround. At LeVic, we’ve been doing this a long time. We handle the tooling, the molding, the painting, the whole thing.

No minimums. No nonsense. Just a team that picks up the phone and gets to work.

Want to see if we’re a good fit? Call us at 816-761-8484 or reach out here.

We’ll walk through it with you—plain and simple.

We look forward to hearing from you soon!