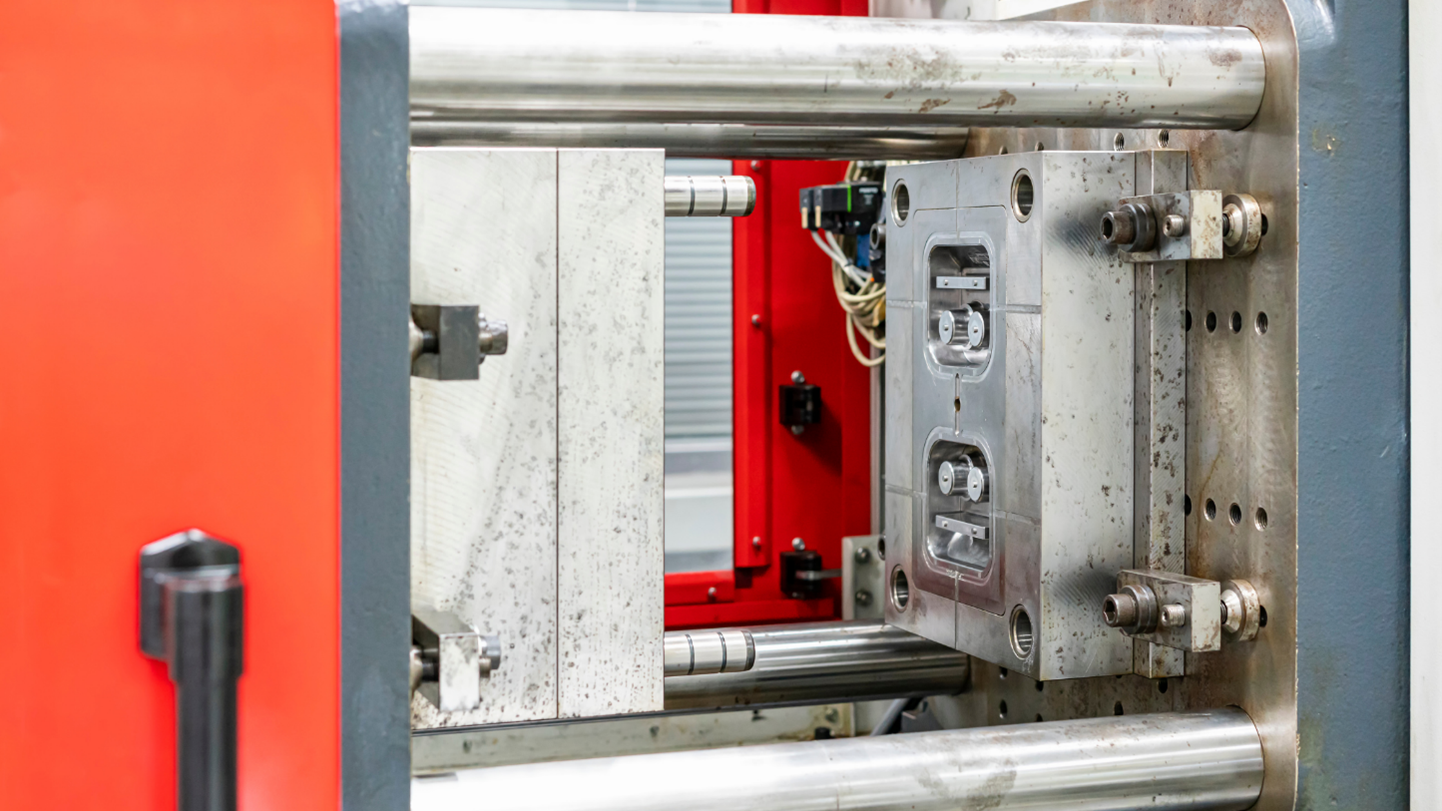

For thicker parts made with custom plastic injection molds in Kansas City, one thing to be aware of is sink marks. These defects can originate from a variety of reasons, including tooling design, material selection, and part geometry. Sink marks can occur when the thickness of the part is oversized for the type of resin that is being injected into a mold. They can also be caused by low pressure in the mold’s cavity or excessive temperatures where the material is injected.

Sink marks don’t have to be the end for parts, and many times they can actually be fixed. As a leader for injection molding assembly in Kansas City, LeVic Plastics has compiled a list of the best ways to resolve sink marks. These include:

- Decrease Mold Temperature

- Add More Holding Pressure

- Extend the Holding Time

- Decrease Wall Thickness

Decrease Mold Temperature

When heat is pulled away quickly from a thicker area, the chances of thicker and thinner areas cooling at completely different temperatures is reduced. Coolant temperatures can be adjusted from the core side to the cavity side, which moves the sink mark. This process must be done carefully to ensure the workpiece does not become distorted.

Add More Holding Pressure

When it comes to plastic injection molding services in Kansas City, sink marks can be caused by low pressure in the cavity. To prevent this, the holding or packing pressure can be increased, since the pressure of molten plastic can have a significant impact on the mold’s stress levels. Although changing pressure levels can be beneficial, they must still be carefully monitored and controlled.

Extend the Holding Time

One way to ensure that each workpiece cools evenly is by holding them for an extended period. Sink marks can be controlled depending on the location of the gates, how close they are to the thicker sections, and if there is time to fill the cavity before freezing occurs. Holding time is a crucial component of injection molding assembly in Kansas City.

Decrease Wall Thickness

When the walls of a given workpiece are too thick, it can result in inconsistent cooling and shaping. As a leader in custom plastic injection molds in Kansas City, LeVic Plastics recommends making walls thinner for quicker and more consistent cooling to help reduce the risk of sink marks.

If you are considering injection molding assembly in Kansas City for your next big project, contact the experts at LeVic Plastics. You can contact us online to receive a free estimate or give us a call today at (800) 231-1232.

We look forward to working with you.