When it comes to CNC machining in Missouri, precision is a key component for designing and crafting the best parts and products for the client. Many engineers and manufacturers will use CNC lathes and turning machines to shape and customize rounded objects. They might also use CNC milling machines to produce a wide variety of shapes like face-milled features or cavities in their workpieces.

Besides lathes and milling equipment, there are other methods of CNC machining in Missouri that are becoming more and more popular. In this article, we will discuss three other advanced CNC machining methods that are being used today.

- CNC Laser Machines

- CNC Electrical Discharge Machines

- CNC Plasma Cutting Machines

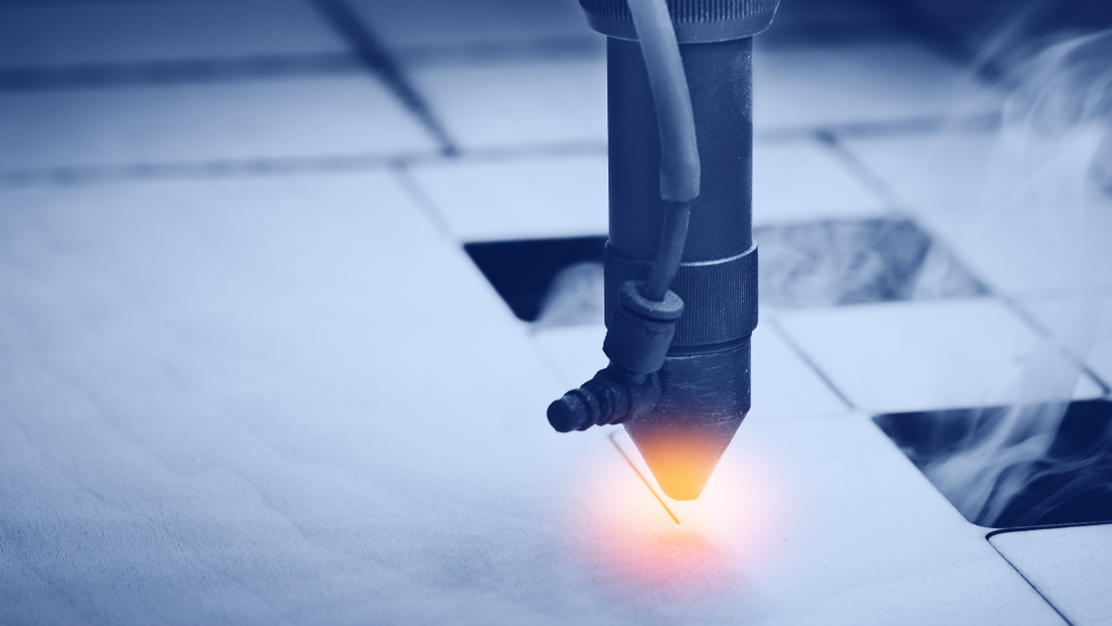

CNC Laser Machines

One of the more advanced Missouri tooling services in use today is the use of CNC laser machines. These state-of-the-art machines can make pinpoint cuts, slice materials, or make customized engravings on a wide variety of objects. The laser will heat a workpiece to a temperature so hot that It melts or vaporizes the material and creates a cut. Lasers allow for more customizations than lathes or mills and produce cuts so precise that no additional finishing processes are required.

CNC Electrical Discharge Machines

Another highly advanced method of CNC machining is the use of electrical discharge machines or an EDM. EDM machining in Missouri utilizes highly controlled electrical sparks to customize and manipulate materials into specific shapes. This process is also known as spark eroding, die sinking, or wire burning.

More specifically, EDM is when a component is placed underneath the electrode wire, and the machine is set up to create an electrical discharge from the wire. These discharges are done with extreme heat, sometimes in excess of 20,000 degrees Fahrenheit. The component’s material is then melted and flushed away with liquids to create the correct shape.

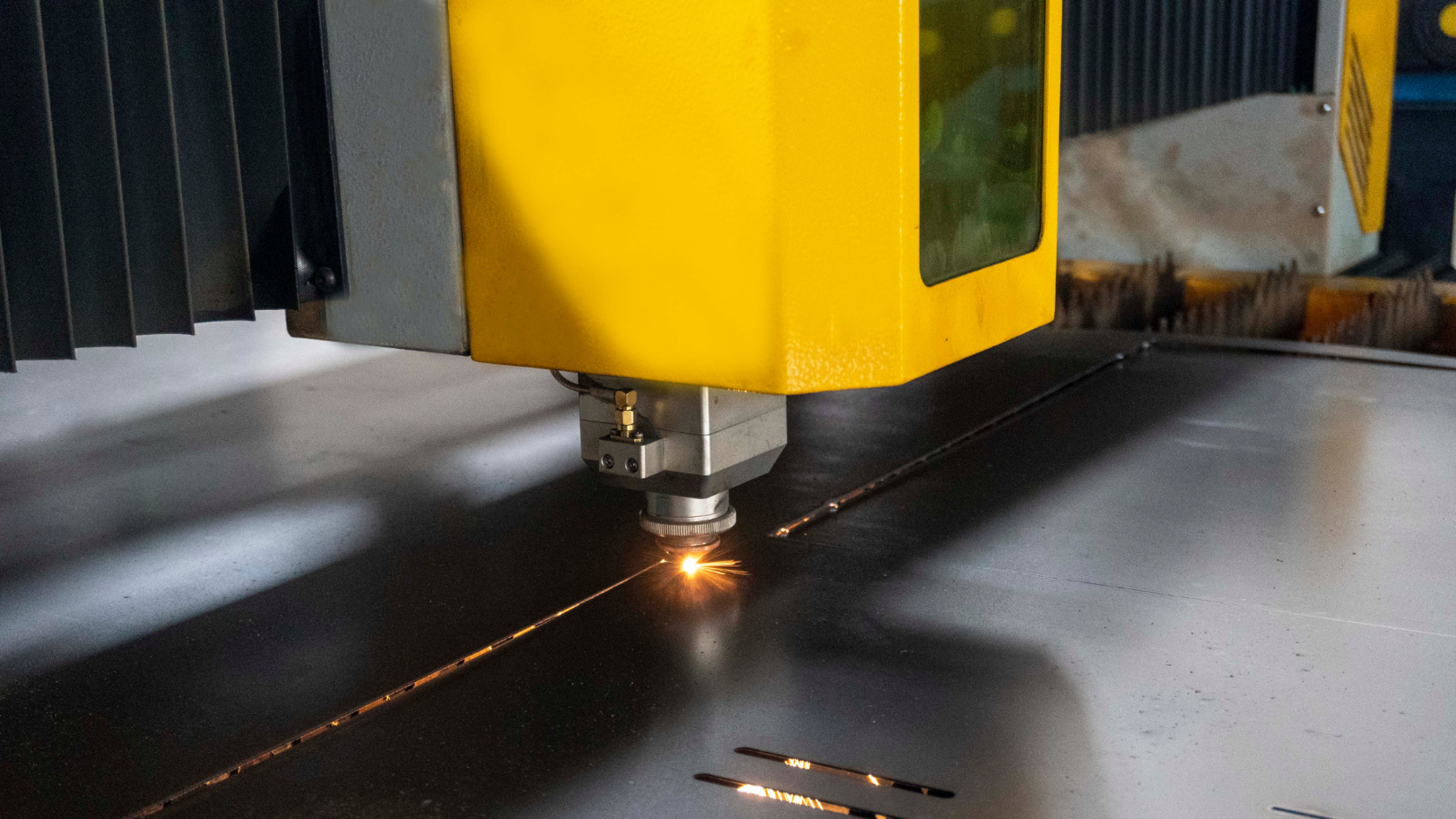

CNC Plasma Cutting Machines

Materials can also be cut by using CNC plasma cutting machines. Some of the highest-powered, electronically-ionized gas torches are used for this method. Similar to other Missouri tooling services involving CNC, plasma cutting involves melting the materials to create precision cuts. What sets this method apart is the amount of heat generated during the process. Plasma torches can produce heat in upwards of 50,000 degrees Fahrenheit.

If you are considering using any of these methods of CNC machining in Missouri for your next project, contact our team at LeVic Plastics today. You can reach us at (800) 231-1232 or contact us online to receive a free project estimate.

We sincerely thank you for considering LeVic Plastics and look forward to speaking with you soon.