When it comes to plastic injection molds, you will likely have two choices: steel molds in Missouri or aluminum molds in Missouri. At LeVic Plastics, we understand that there are benefits to using either steel or aluminum for custom plastic injection molds in Missouri. This article will focus primarily on the benefits of using steel molds.

Some of the areas we will cover today when it comes to steel molds in Missouri are:

- Higher Volume

- Aggressive Materials

- Durability

- Complex Parts

- Finish Options

- Design Modifications

Higher Volume

Steel injection molds have the strength to handle numerous cycles before they need to be replaced. Steel is more capable of handling high injection pressure and temperature than other molds.

Aggressive Materials

Over time steel molds in Missouri will become hardened and more durable through heat treatment. This hardening process makes the molds stronger and capable of handling the most aggressive of materials. Many aggressive materials require higher temperatures and injection pressure, which only steel molds can handle.

Durability

Many facilities specializing in custom injection molding in Missouri prefer steel molds because of their durability. Steel is corrosion resistant while maintaining thermal stability. Steel can stay intact longer and achieve higher production cycles.

Complex Parts

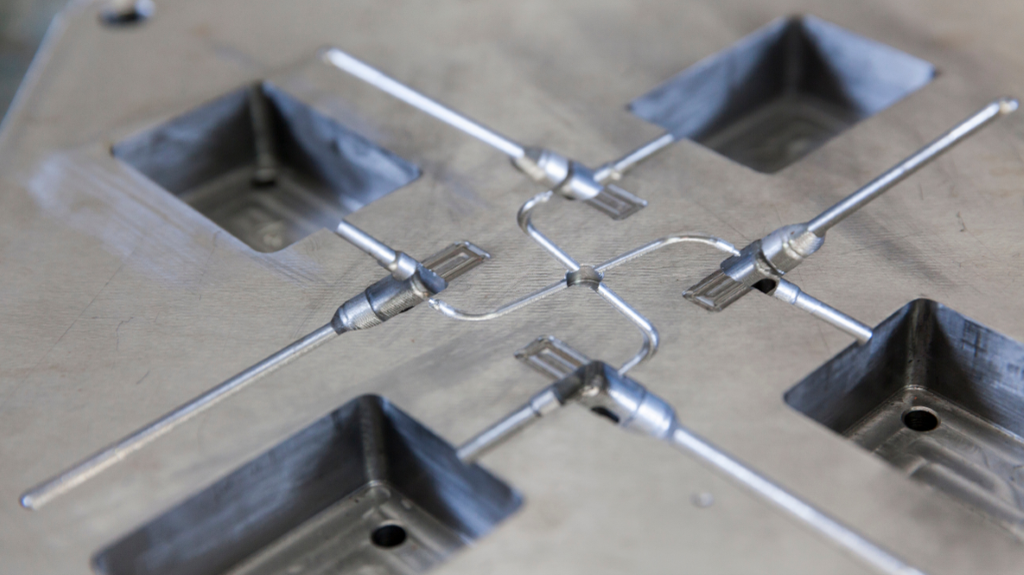

If the design of a part is unique, and a detailed mold design is required, a steel mold may be the only option. The durability of steel will help ensure accuracy in all parts, no matter how unique the design.

Finish Options

When it comes to the final details and finishes for parts, steel molds are the best option. Steel is high in density and allows for more texture selections, which gives parts the extra detail to make them stand out. Steel inserts can be added to the tooling to allow taller, more in-depth details for each part.

Design Modifications

A steel mold can be modified by welding if a part re-design is required. If your part is likely to undergo design revisions, then steel molds are the right choice for you.

Flash

The hardness of steel molds significantly decreases the risk of flash on a part. Aluminum molds in Missouri are at a greater risk of flash since it is a softer material.

If you are unsure whether your project is best suited for steel or aluminum molds, LeVic Plastics can assist you with any questions you might have. Call our team today at (816) 761-8484 to discuss your next plastic injection project.

We offer service for limited production runs in Missouri as well as the most extensive projects for plastic injection services. LeVic Plastics looks forward to working with you!