When it comes to the mass–production of parts or products, there are many different techniques that companies use. One method that is gaining momentum is EDM machining in Kansas City.

The EDM Machining Process

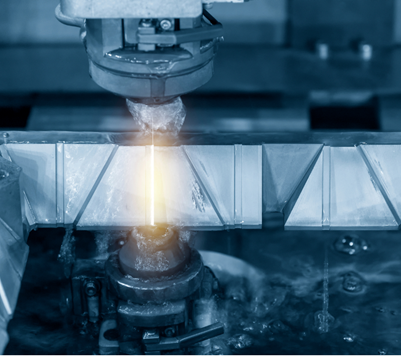

Electrical Discharge Machining in Kansas City (EDM) is a controlled metal-removal process. More specifically, EDM uses two electrodes separated by a dielectric liquid. This liquid is used so that the metal can be removed by electric spark erosion.

The electric spark in EDM is used to cut and shape the piece into the final model of your desired shape or size. After the cutting process, a high–powered electric charge pulsates the finished product; this removes all tiny pieces of metal from the model in a controlled fashion.

Benefits of EDM Machining in Kansas City

You may ask yourself, “Why should I choose EDM instead of another process like CNC machining in Kansas City?” Some of the advantages of EDM that we will explain more in-depth are:

- Creates Complex Designs or Shapes

- Cost-Efficient

- Clean Surface Finish

- Precise Holes

Creates Complex Designs or Shapes

Companies specializing in tooling services in Kansas City, such as LeVic Plastics, know that EDM is the best option when it comes to the most unique shapes or designs. Even the thinnest, most fragile designs can be completed in less than time than using conventional cutting tools.

Cost-Efficient and Versatile

EDM can handle high-precision material components and cut them much more accurately than traditional cutting methods. The risk of having to redo any work is minimal, thanks to the accuracy of EDM Machining in Kansas City. Also, the process of EDM is typically much more energy efficient than traditional drilling or milling machines.

Clean Surface Finish

EDM machinery is designed so that the most delicate portions of the work pieces are machined without any flaws. There is very little polishing required at the end of the process, which helps ensure that each piece’s shape is not disrupted.

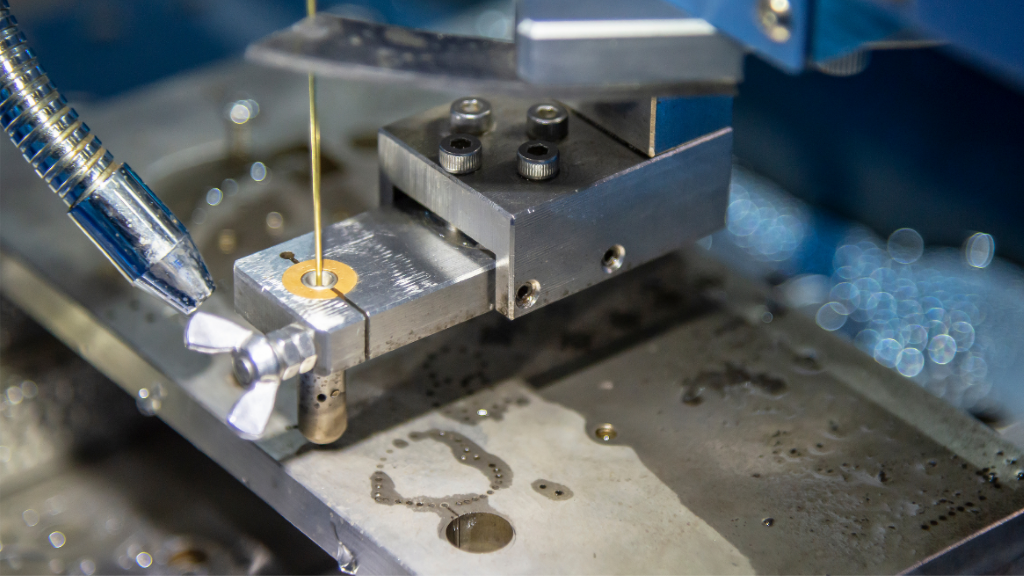

Precise Holes

Small holes are required for many work pieces, and the hole’s size must be extremely accurate. EDM has pinpoint precision and the process creates no mechanical stress between the work pieces and tool as they do not make contact at any point.

If you are looking for an experienced company when it comes to EDM Machining or any other tooling services in Kansas City, give LeVic Plastics a call at (800) 231-1232 or contact us online to receive a quote from one of our team members.

Since 1971 Levic Plastics has been the best “one vendor” answer for or smaller, limited production runs in Kansas City or the largest projects. We can truly handle it all, so give us a call and let us know how we can assist you.