Nowadays, plastic injection molding services is an ever-growing industry. Custom plastic injection molds are used to make just about anything and everything you can think of. However, not every piece of plastic is made (or molded) the same way. There are many different types of plastic molding that people use depending on what is being made. This article is part two of the different types of plastic molding, where we will discuss thermoforming, compression, and extrusion molding.

Thermoforming

Thermoforming is a plastic molding technique where thermoplastic is heated to a flexible temperature, formed in a mold to produce a specific shape, and trimmed to create a usable product.

Conventional products produced from thermoforming include:

- Disposable cups

- Lids and clamshells

- Trays

- Blisters

- Automotive parts

- Food and retail products

Extrusion Molding

Extrusion molding is one of the more unique molding processes out there. It is fairly similar to the process for making custom plastic injection molds, except that it does not produce a long continuous shape. Instead, extrusion molding uses a custom die (not a mold), and the products are made by squeezing melted plastic material through the die, creating a long, tubular shape. The final product is determined based on the shape of the die rather than the actual mold.

Extrusion molding is ideal for creating:

- Tubes

- Pipes

- Straws

- Hoses

- PVC pipe

- Plastic gutters

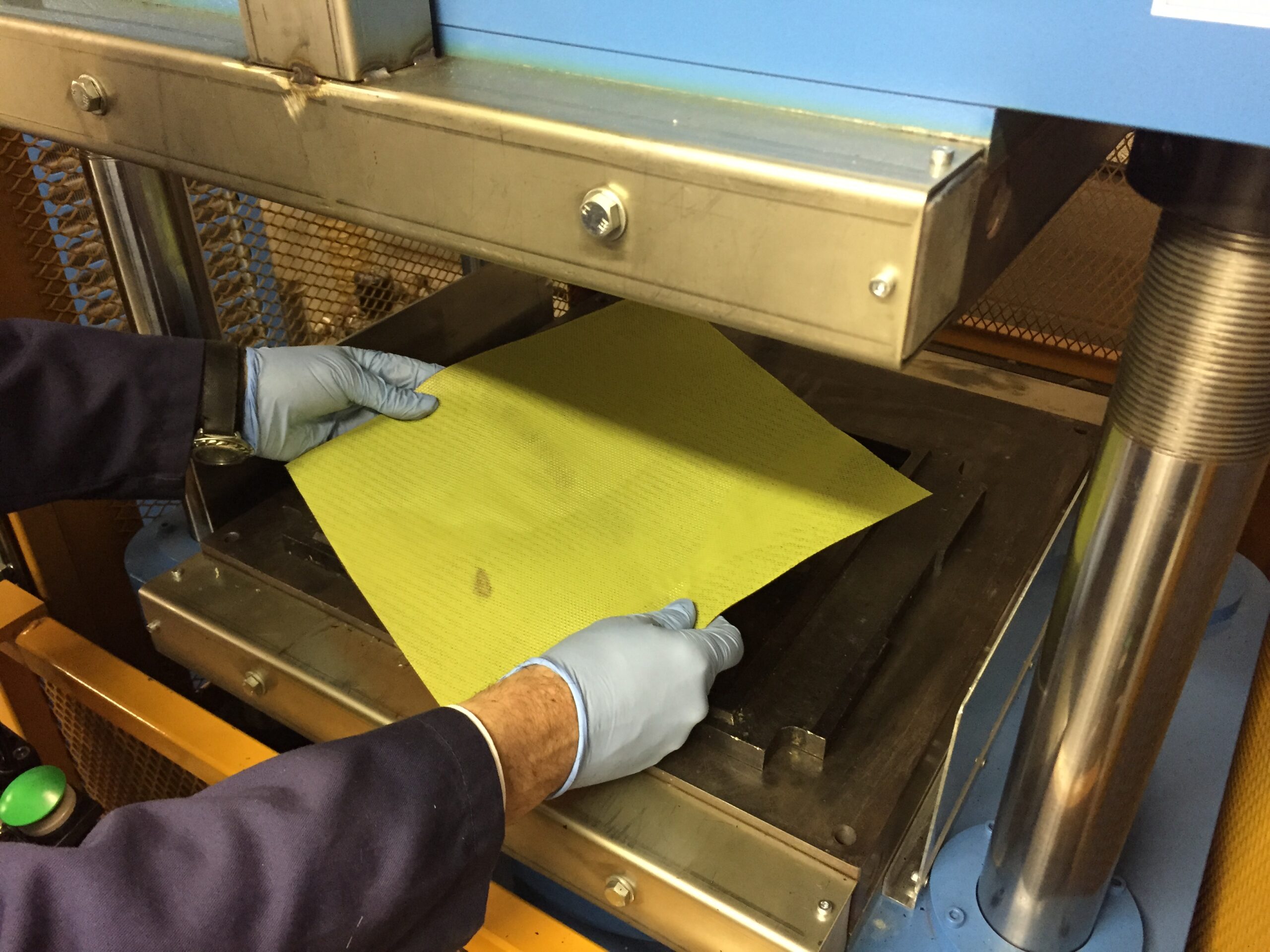

Compression Molding

During compression molding, heated plastic is placed in a heated mold and then is closed to compress the plastic into a particular shape. Once the compression happens, the heating process, known as curing, occurs to ensure the final product will maintain its shape and strength.

There are many advantages of compression molding. It is a cost-effective and very efficient process for producing a variety of products. Additionally, compression molding yields extremely strong and durable parts by using materials like fiberglass, thermosetting resins, and reinforced plastics.

Uses of compression molding:

- Replacing metal parts with plastic

- Automotive parts

- Household appliances

- Body armor

Contact LeVic Plastics

Contact our team here at LeVic Plastics for custom plastic injection molds in Missouri and the Kansas City area. Since 1971, we have continuously strived to offer the most precise, workable, and economic prototype research and production facilities available. We are your one stop shop for everything plastic injection molding related. We build, make, paint, assemble, and ship the part(s) you need. Give us a call today at 800-231-1232 to learn more about our plastic injection molding services in Missouri.