The process of CNC machining in Kansas City involves removing material from a block and customizing that block into a specific design, size, or shape. This process requires a variety of tools in order to achieve the desired results. Whether it’s milling or lathe tools, every machine shop requires the right equipment to ensure that all parts and products are engineered to meet exact specifications.

The process of CNC machining in Kansas City involves removing material from a block and customizing that block into a specific design, size, or shape. This process requires a variety of tools in order to achieve the desired results. Whether it’s milling or lathe tools, every machine shop requires the right equipment to ensure that all parts and products are engineered to meet exact specifications.

Here are some of the tools considered to be the most essential when it comes to CNC machining in Kansas City.

Face Mills

A machine typically will need to flatten a workpiece to meet the designer’s specifications. Face milling can aid in preparing a flat surface by using a variety of tools. Face mills have multiple interchangeable cutting inserts that allow for a variety of cutting profiles without the need to change an entire tool.

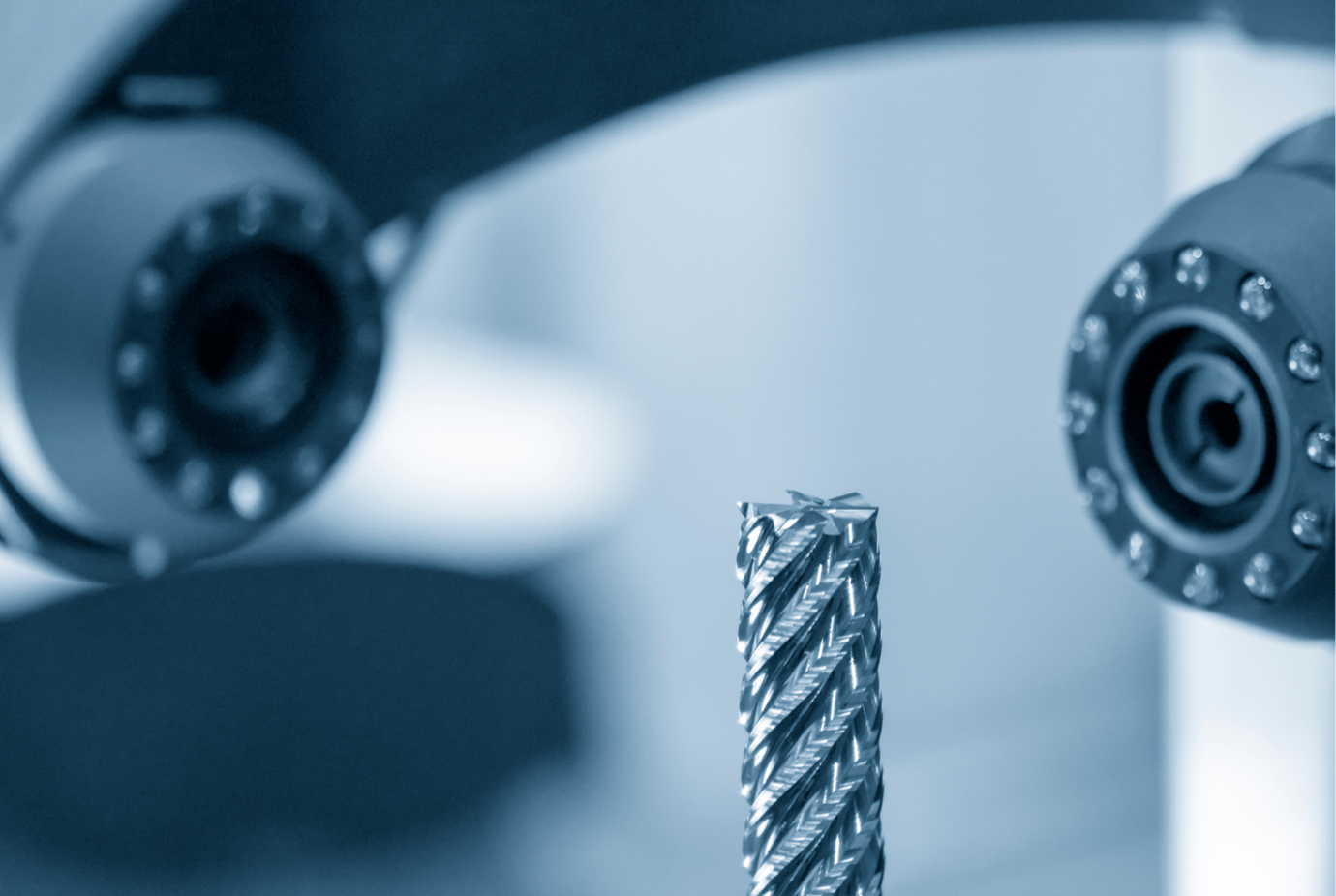

End Mills

Vertical CNC machining in Missouri is done frequently by using end mills. To create detailing on the workpiece’s surface, end mills are used to help finalize contours around the edges. Using their sharp flutes, end mills can cut and remove materials swiftly. The most common types of end mills are flat, ball nose, bullnose, and roughing. Each mill is used for specific shaping and customizing.

Slab Mills

Known to many as plain mills or slab cutters, slab mills are used to make cuts on flat surfaces. Slab mills can be used for wide, narrow, and deep cuts, depending on the size of the mill. You will typically see slab mills used with manual cutting more than with modern machines. Slab mills are also used on universal milling machines on large surfaces.

Hollow Mills

The best way to describe a hollow mill is a “pipe-shaped” cutting tool with multiple cutting edges on the inner face. Most hollow mills have a minimum of three cutting edges, but some have as many as eight. Hollow mills are commonly used for chamfering, facing, and centering.

Gear Cutters

The manufacturing industry would be lost without gear cutters. These specialty cutting tools are designed specifically to make metal gears needed for many manufacturing machines. Gear cutters can shape several different types of gears, including:

- Spur

- Bevel

- Screw

- Worm

- Single-Helical Gears

- Double-Helical Gears

Drill Bits

The most common tool used for CNC machining today is the drill bit. They are very similar to ones you would use at home or would buy at a local store. Like a regular drill bit, CNC machining drill bits are designed to quickly drill holes into a workpiece. Drill bits are typically broken up into three categories: twist, center, and ejector. Each type of bit is designed to created holes and shapes of different dimensions.

Thread Mills and Taps

External threads on a workpiece are created by using thread mills, while taps are used to create internal threads. Most thread mills and taps have a very small diameter to ensure that they are more precise. Threading while using a tool with a large diameter at times can end with very poor results.

Reamers

Rotary cutting tools used in metalworking to drill tiny, precise holes are known as reamers. Precision reamers are used to enlarge holes precisely and smooth the edges, while non-precision reamers are used to remove burrs and provide basic enlargement.

Fly Cutters

Fly cutters are used to machine larger surface areas. Although the cutting process takes longer than using a face mill, fly cutters typically provide a more uniform and smooth finish.

At LeVic Plastics, we used the highest quality techniques to make quality parts and products for our customers. Whether it’s EDM machining in Kansas City or plastic injection molding services in Kansas City, we will get your project complete in the most friendly and efficient way possible.

Give us a call today at (800) 231-1232 to find out about the latest tooling services in Kansas City and to get started on your next project.