If you are in the planning phase of an injection molding project, you will have one very important question to ask yourself, “Should I use aluminum molds in Kansas City or steel molds in Kansas City?” This article will provide the pros and cons of each choice, which should help make your decision-making process a little easier.

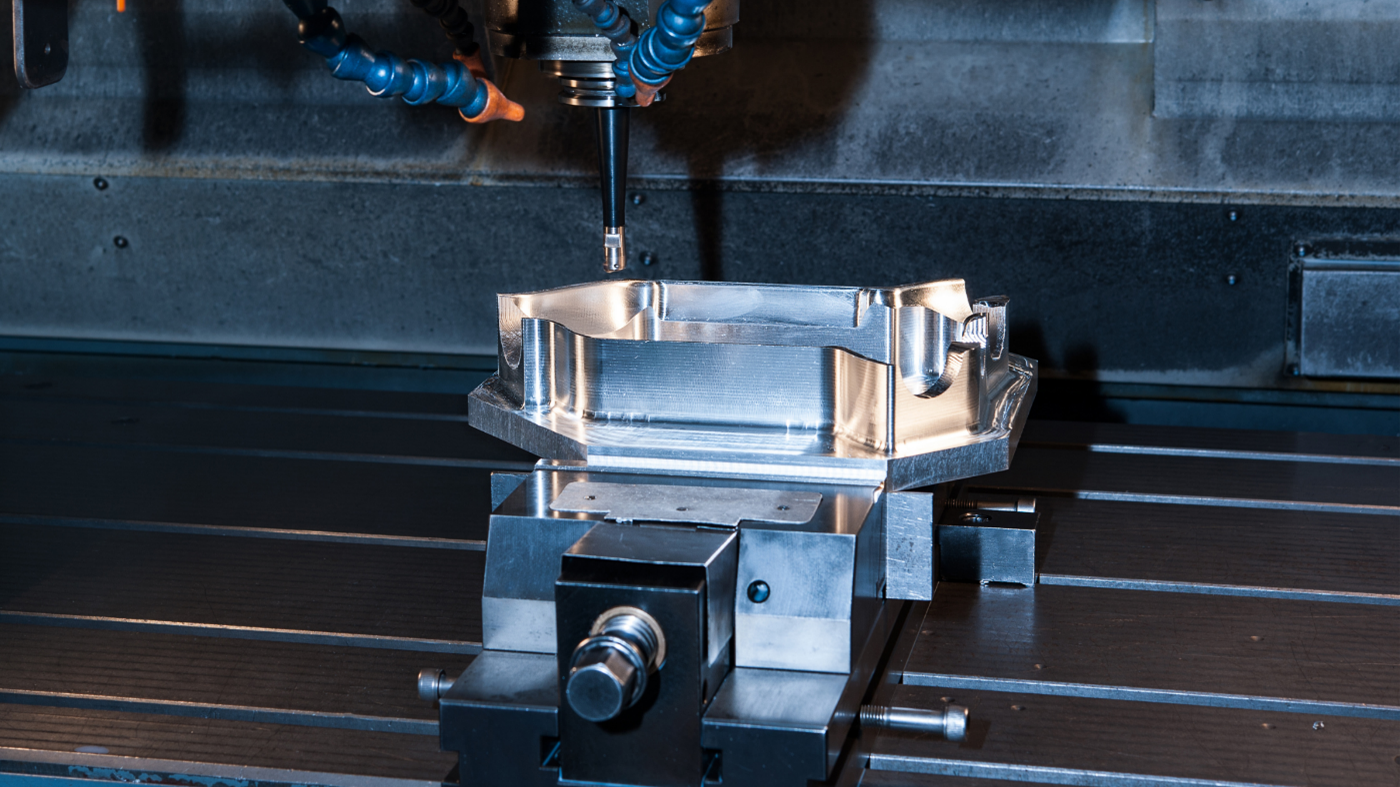

Aluminum Molds

Some of the most distinctive qualities of aluminum molds are that they are very lightweight, resistant to heat, easy to shape, and resistant to rust. Although steel is an excellent option, there are several reasons why many consider aluminum molds in Kansas City to be the better choice.

More Cost-Efficient

No doubt, you have probably heard through news outlets about the rising cost of steel in the United States. If you are looking for a way to cut manufacturing costs for your project, you may want to consider aluminum molds. Aluminum is widely known to be a less expensive option than steel for many products, molds in particular.

Less Temperature Fluctuation

Aluminum tends to stay closer to its original temperature compared to steel. This means aluminum will cool down to its ideal temperature quicker and configured to the ideal size. This helps speed up the manufacturing process because there is less time wasted on waiting for molds to cool down.

Easier to Repair or Adjust

The flexibility of aluminum makes it easier to make adjustments on the fly during production. This is very beneficial when there is some type of error during the production process.

Steel Molds

The defining qualities of steel compared to aluminum are that it is the more durable and rugged material of the two. Aluminum is a great option for specific types of production, but steel molds in Kansas City are widely regarded as being higher quality overall.

Ideal for High Volume

The strength of steel molds makes it the best solution for larger orders. As long as steel molds receive the proper maintenance, they will remain extremely durable for large production runs. Aluminum is typically used for limited production runs in Kansas City.

Highly Detailed

The hardness of steel makes it the perfect choice for items that require lots of detail. Aluminum can bend, especially in areas where detailing is very specific, so many manufacturers prefer steel to ensure the utmost accuracy during production.

Compatible for All Resins

Steel is versatile and can accommodate all types of plastic resins. No matter if it’s standard plastic or advanced formulas, steel has the strength and durability to handle any type of material.

Now that you know what separates aluminum molds in Kansas City and steel molds in Kansas City, you can make an informed decision on which will be best for your next project. If you still have questions, no problem, contact our team at LeVic Plastics today. You can give us a call at (800) 231-1232 or contact us online and receive a free quote.

We look forward to working with you.